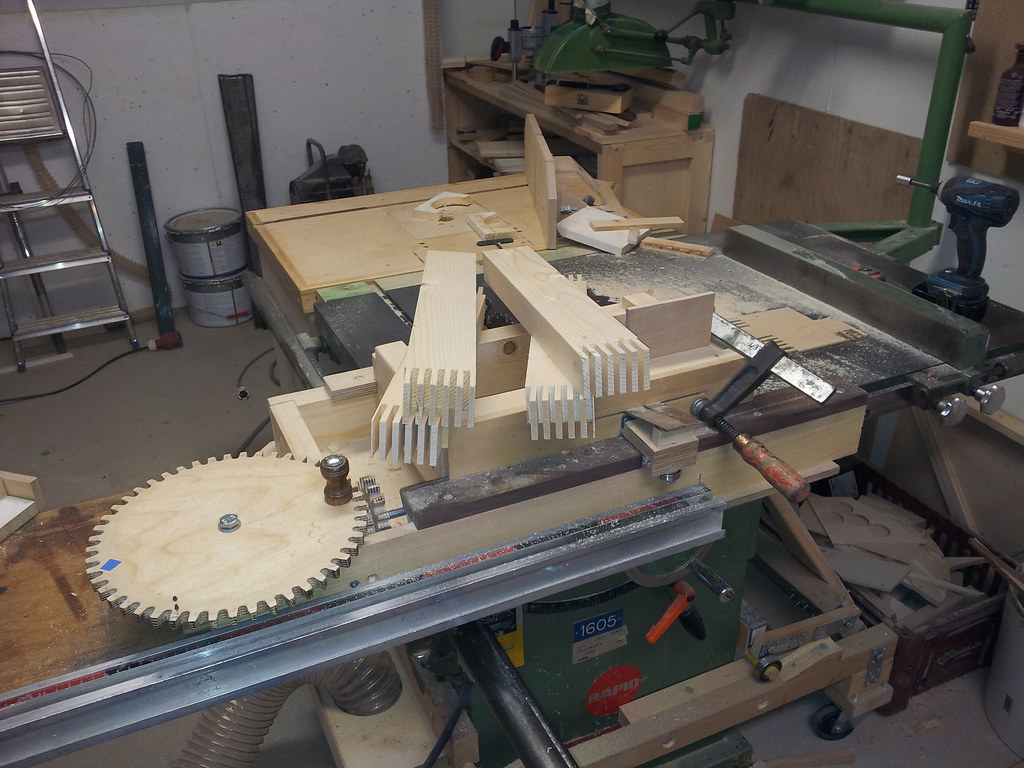

Screw advance box joint jig using Matthias Wandel plans:

Instead of a guide bar I have it bolted to the sliding table. I put threaded inserts in the table that line up with the jig, so it'll always clamp down in the same place.

Instead of a guide bar I have it bolted to the sliding table. I put threaded inserts in the table that line up with the jig, so it'll always clamp down in the same place.