Lord Nibbo

Established Member

OK, Keep me down for ally.

Dibs-h":1aqsmzdv said:Looks like we have about 8 for Aluminium - I think it would be safe to say, there will be a batch of Aluminium ones (can't see us not getting 2 more - ). :lol:

As well as a batch of Mild Steel.

Now for those wanting Steel plates - I suppose there would now be the option of getting all the rings in Aluminium. We'd just increase the rings for the Aluminium batch. Although the Aluminium rings are a little more - would this interest folk?

head clansman":flsct0jl said:hi dibs-h

can you include me please , if you can , can i have the alum 8m + all alum rings with all holes drilled and tapped, hope that is not a problem is it?.

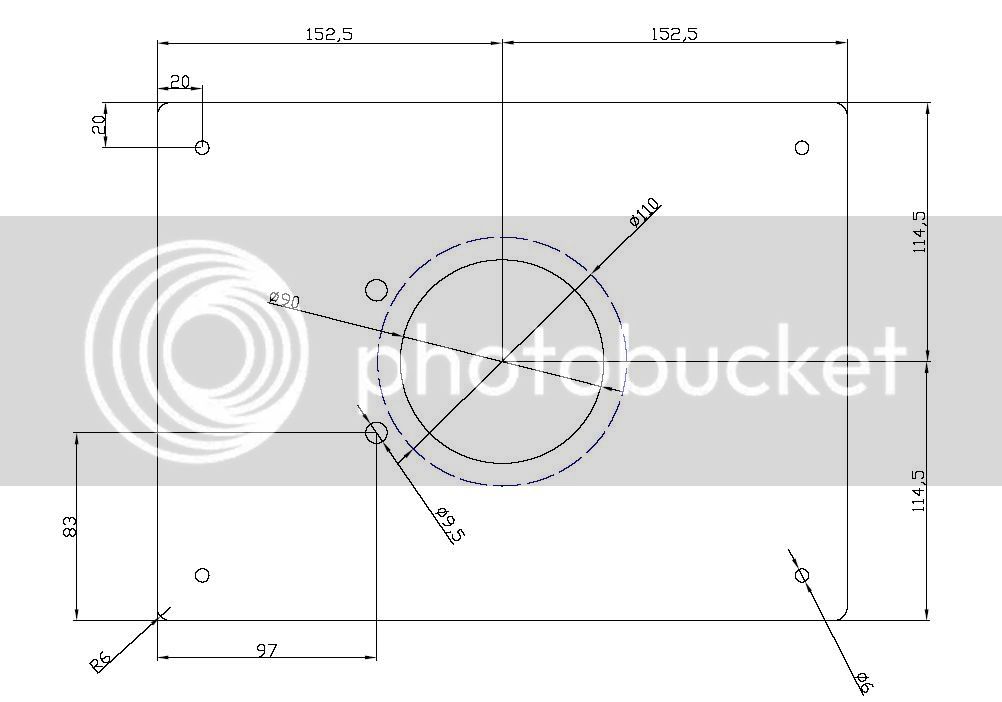

I think you will find the 9.5mm is the larger size (on the MLCS it is) the reduced bit on the MLCS is 6.3mmDibs-h":3oiovxms said:Now on the web - the Trend lead on pin is listed as

25.4mm long x 9.5mm diameter

so I've put the dia of the hole as 9.5mm. Could someone measure the diameter of the reduced bit to confirm?

Looks near enough.I've set the corner mounting holes 20mm away from each edge (again just "looks about right") so if you want different, I'll change it. Also the corners have been radiused at 6mm?

I hope the shoulder depth will be the same for both Aluminium and MS, and the slightly deeper recess on the plate also seems a good idea.The shoulder - someone mentioned insetting it by 3.1mm not 3.0mm - allowing the use of a paper shim? Good idea, bad idea? I think the shoulder should be the same depth for both Aluminium and MS - allowing folks to use rings\discs interchangeably.

chris_d":y1epjtk2 said:Hi Dibs,

Thanks again for all your hard work in facilitating this opportunity!

A minor comment on your dimensioning style - the use of a fixed datum point is encouraged from which all other dimensions are referenced to prevent acculmulation errors?

Apologies if you know this and were just showing a quick sketch.

Cheers,

C

Enter your email address to join: