wobblycogs":3fdimb9b said:

Hope you don't mind me asking but I for one would be really interested in hearing about what your SE has to say about your basement works. My long term goal is to turn our smelly damp basement into a useful fairly dry space, probably not living space more like somewhere I can store garden tools and logs etc. Any hint / tips / info is always well received

Cheers

If folk are interested - I can continue the thread with the garage\basement build or do a new thread? Or no thread? There will be a bit of a pause between the shop being plastered, to when the internal fitting out takes place. That will have to wait a little as I'm going to have to empty the garage out and it has to be stored somewhere.

For the basement - I'll be excavating about 1m down from the current level between the existing garage & shop. (Not looking forward to that as it's about 24 cubic meters, a damn sight more than for the 'shop). The drystone wall will be taken down and replaced with the Heras fencing.

SE is fully on board with the basement side of things.

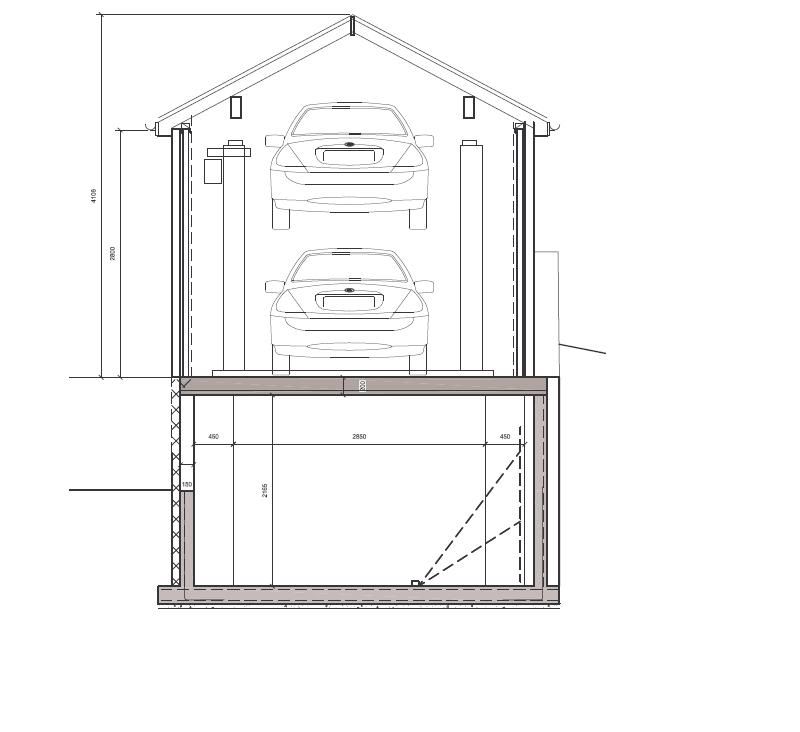

Approx details are 1' reinforced raft\slab with a ground beam where it adjoins the end of the 'shop. Along the back wall there will be a retaining wall which will be finished with 1 skin of drystone wall, so the neighbours side looks like it currently does. Cast pillars going up the side - which should protrude into the basement once it's been finished, but by how much isn't yet finalised. These will tie in with a large amount of rebar in the garage floor - creating a localised reinforcement in the garage floor, going across the garage floor. This is to take a 2 post car lift in the garage - and the floor to effectively take the load of a car on the floor, lift in the floor and a car on the lift. The garage floor will be cast in-situ using the metal deck that you see used in commercial builds.

On the garden side there will also be a retaining wall, but not as high as our garden will be re-leveled. I also suspect the short side towards the drive will also have a retaining element. The initial thoughts are to fit a rubber type of membrane to the outside and cover it with a protection board. And\or internally render it with some of the Cementious slurry type of product and then couple of coats of Synthaprufe. The retaining walls - I'm expecting to be block - space with mesh and then block. The gap will be filled with concrete. Will be discussing whether waterproof concrete might be an option.

For an existing space - it's a bit different. Is your space ventilated? You'd be surprised how much difference that can make.

Dibs

p.s. Here's a picture - sort of WIP, need to finalise a few things yet.