Ttrees

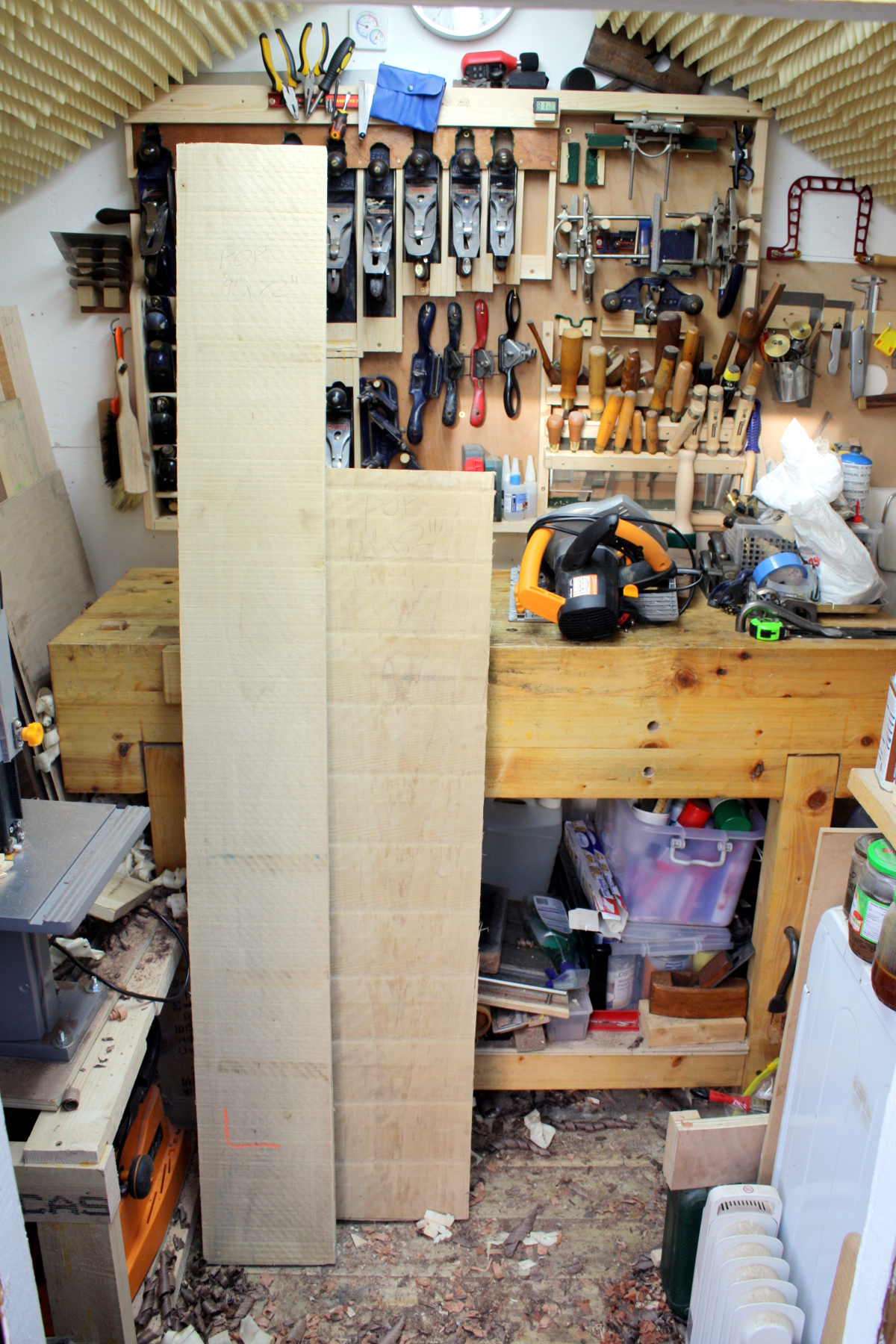

Iroko loco!

Some nice work folks

Donovan, that crib is fantastic, you will get lots of commissions for them by the looks of things.

Naz nice looking wee drawknife , did you temper the steel on it?

I just made use of a plumbing ferrule yesterday, they're interesting to work with.

Donovan, that crib is fantastic, you will get lots of commissions for them by the looks of things.

Naz nice looking wee drawknife , did you temper the steel on it?

I just made use of a plumbing ferrule yesterday, they're interesting to work with.