Not quite today, but I did finally finish the crib/cot bed I'd been working on for a *very* long time. I did it all with hand tools except for resawing the wood for the curved rails.

It was definitely an experience. The lumber was horribly expensive, and I'd paid to have it jointed/thicknessed for me since I didn't want to do it with the few planes I had at the time. Unfortunately I'd just assumed that it had arrived properly dimensioned, and properly dried... which was foolish of me. everything was cut wrong, thicknessed wrong (no two pieces the same thickness, no board the same thickness at both ends), and it wasn't until half way through the project that I realised the wood was still very wet when it had arrived. I'd made the side pieces and then moved on to the end sections, and when I'd come back to fit all the parts together the sides had warped significantly. Then I watched the end sections warp as they dried too. Doing the math I figured the wood must have been around 16-18% moisture when it arrived, rather then the 8-10% I'd have expected.

Still, aside from a glue discoloration from having to scrap through an entire layer of veneer on two of the end pieces (which I can still fix, once I get to where the crib is again), the thing turned out reasonably well. In January I'll go to where the crib is and to the last bit of tweaking and apply another layer of beeswax, but all in all it was a messy, frustrating, expensive, and downright horrible experience that I'd do again in a heartbeat. A bad day in the workshop is still a pretty darned good day.

the lighting isn't good in these pictures - it's not ultra shiny, but it does have a lovely lustre to it when you see it in person. The finish is simply oil (Osmo top oil I think?) and beeswax.

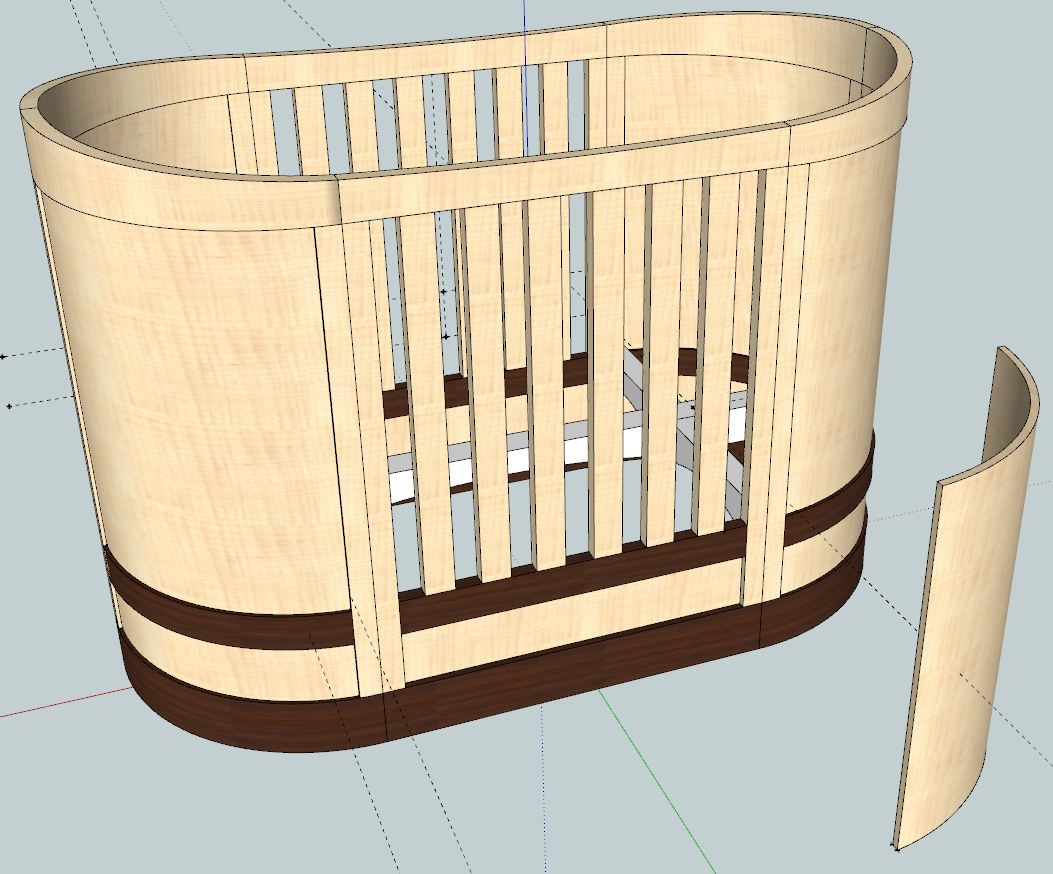

the internal frame didn't end up being needed, but the sketchup model was pretty close to the finished project.

Sketchup

finished crib with height adjusting platform.