Had banter with my workmates kid about how he needs to earn a spare electric screwdriver i have, by behaving- then dad decides when he's earned it.

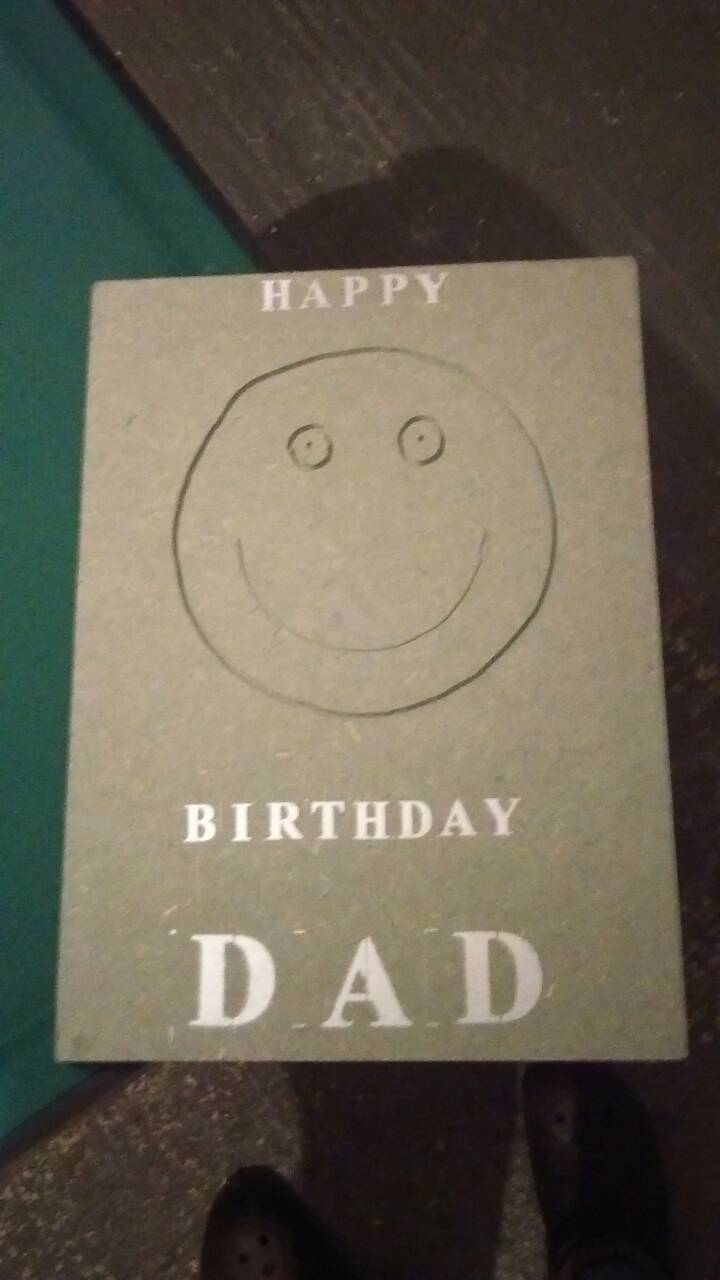

Got him on a router with a v groove cutter.

I think he's done a really good job making a postcard/birthday card for his dad's 40th.

First time he's ever used a router. I was well happy he made something that him and his dad will remember.

I told him he did such a good job I'd give him the charger to his electric screwdriver he hasn't earned yet as a reward ! :lol: there were chuckles !

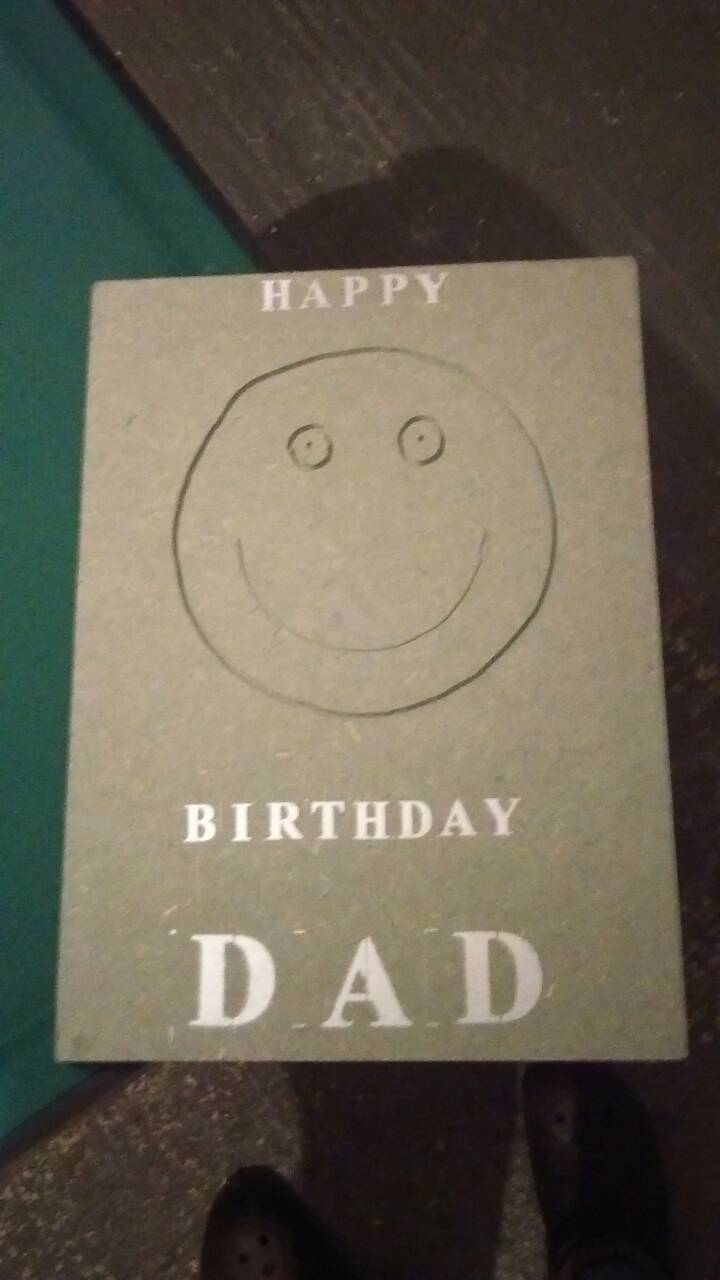

Got a lick of paint on......

I ain't afraid of no ghost !

Coley

Sent from my SM-G900F using Tapatalk

Got him on a router with a v groove cutter.

I think he's done a really good job making a postcard/birthday card for his dad's 40th.

First time he's ever used a router. I was well happy he made something that him and his dad will remember.

I told him he did such a good job I'd give him the charger to his electric screwdriver he hasn't earned yet as a reward ! :lol: there were chuckles !

Got a lick of paint on......

I ain't afraid of no ghost !

Coley

Sent from my SM-G900F using Tapatalk