MattRoberts":22tjzfe8 said:

woodbrains":22tjzfe8 said:

MattRoberts":22tjzfe8 said:

Check out woodgears.ca - Matthias created some deep throat C clamps

https://youtu.be/5U7ufIyBaos

Hello,

They look absolutely useless! Sorry to sound negative, but the pressure required for a glue up would exceed the destruction point of that clamp by a phenomenal amount. But then I don't think the guy understands how glue works, from some of the things he's witten.

Mike.

Interesting, what are you basing your views on? He's been using the clamps for years, and has built two large bandsaws, a home made surface planer, multiple clamps, a panto-router, two dust extractors and various other woodworking machinery using wooden components.

But you could be right - he might not have much of a clue.

Hello,

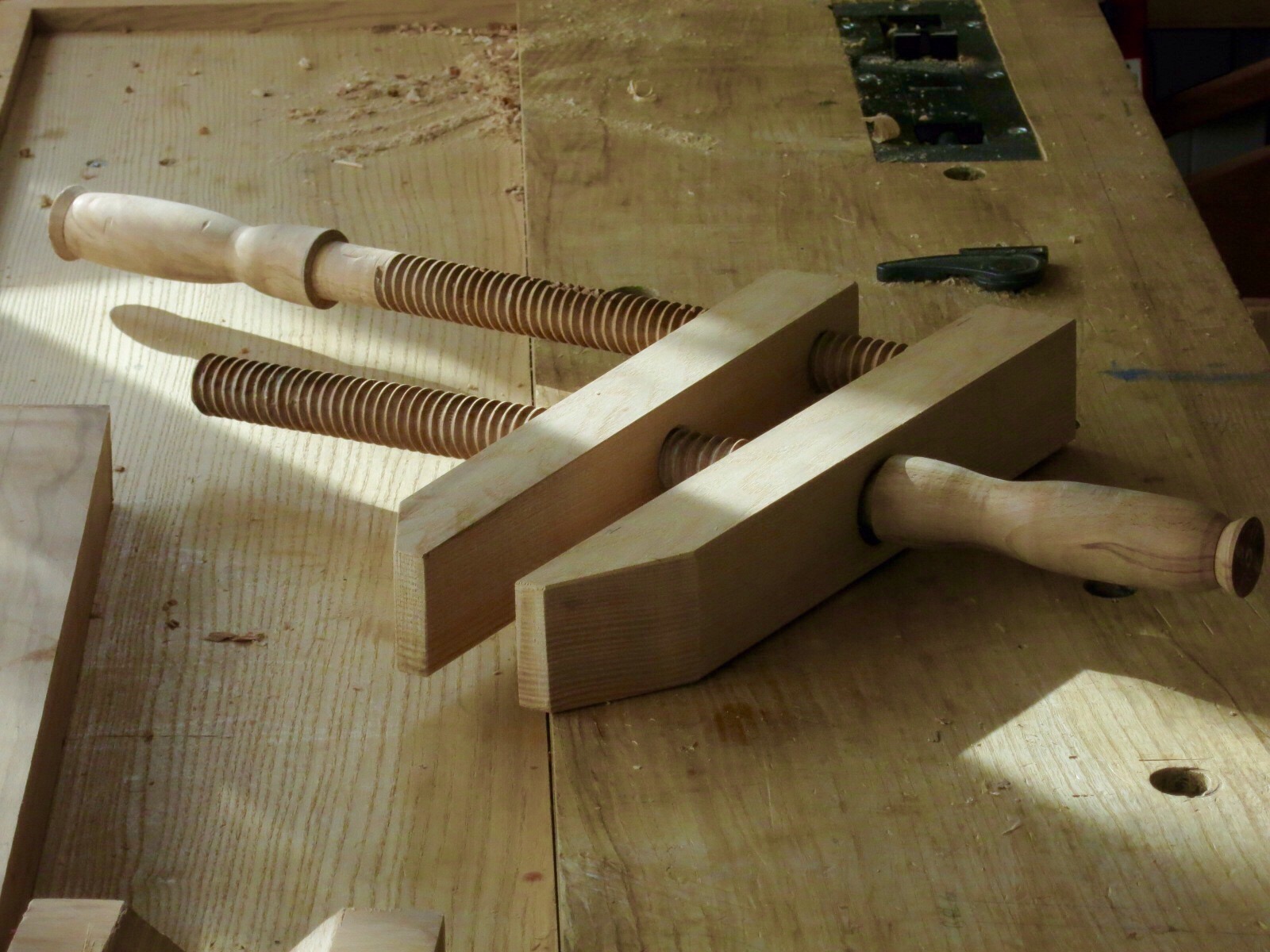

Look, for some light duty work, they may be OK, but consider this : I have destruction tested bridle joints, mortice and tenon etc, and what did i use to apply the pressure: G cramps! They did not even come close to the maximum pressure available to the g cramps, nor my hand strength. I generally apply more pressure with my clamps during my glue ups. Those wooden clamps are a lever where the load is the joint, and the mechanical advantage is the length of the arms. The force applied to the workpiece by the screw needs to be quite high and this is magnified by a great many times at the joint, and the deeper throat the clamp the greater the strain on the joint.

Also, when clamping, the pressure applied to the workpiece is only available in an area below a 'cone' spreading out 45 degrees beneath the clamping pad. So there is very little spread of the clamping pressure on the work piece. Since glue requires continuous pressure across the entire area to be stuck, we have to either use many, many clamps, usually too many to fit into the space without causing clashes, or use thick clamping blocks to increase the size of 'cone' to spread the pressure over a larger area. Since pressure decreases as the area increases, we have to add even more clamping force to the clamp screw to get enough pressure. The strain on the wooden clamp's joints is immense.

As another poster said, the French have used wooden clamps, historically. But I would suggest they were gluing their work with hot hide glue, which does not need the high clamping pressures of PVA, it's derivatives, polyurethane and UF etc. If wooden clamps were practical, there would be vast quantities of them in every wood shop everywhere as, after all they can be made as easily as any frame that is made commonly and cheaply by woodworkers. But wooden clamps are very rare and the often expensive cast iron variety are ubiquitous. For a good reason.

Incidentally, Mr. Wendell is indeed a talented Inventor. But the internet has given him notoriety over the many others who make their own tools without advertisement. Before I was 20 or so, long before YouTube video was even thought of, I had made a 3 wheeled bandsaw, wood turning lathe (2) tablesaw and fence system, sliding table, crosscut saw for a plunge cut circular saw that was more versatile than a tracksaw with parf dogs as I could trench on mine and dimension narrow stock etc, more like a RAS. Using materials like old bikes, wheelchairs and scrapped pillar drills. I had no welding gear nor any machinery better than an electric drill and the machines I previously built. All metal was joined with rivets and everything else was made with mostly reclaimed wood. Every sort of fixture and accessory you could think of.

Obviously, since then, I've made every sort of router jig, tenoning jigs, router tables by the shed load, several cabinet makers benches, a 5 by 6 metre workshop, hand planes and other hand tools, the list is endless.

I'm not short of a little experience with these sorts of thing!

Mike.