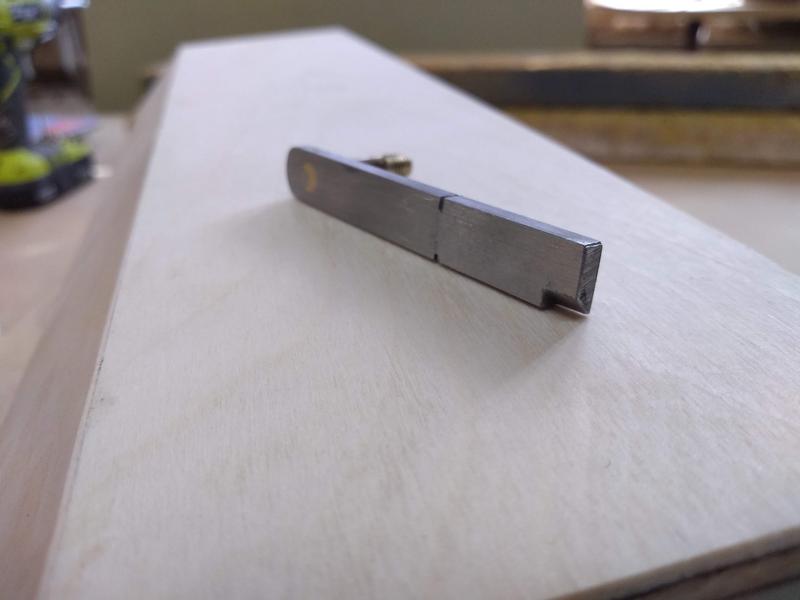

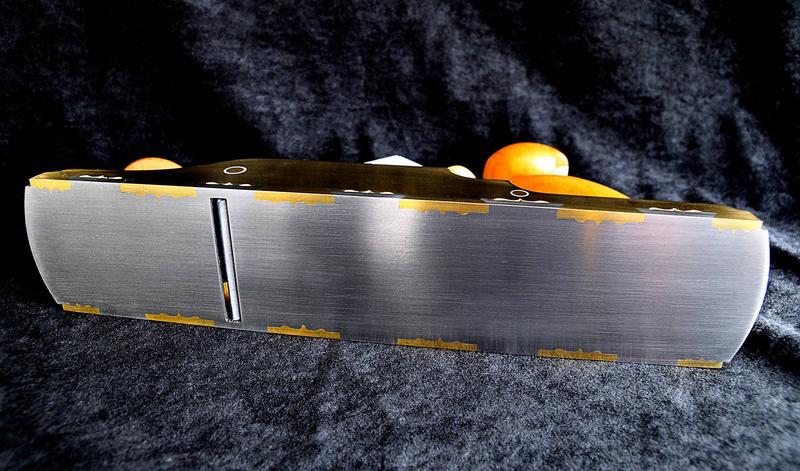

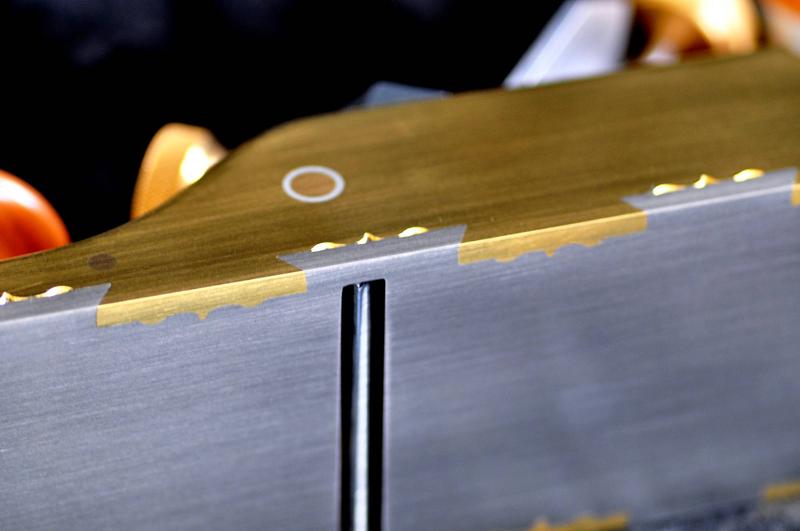

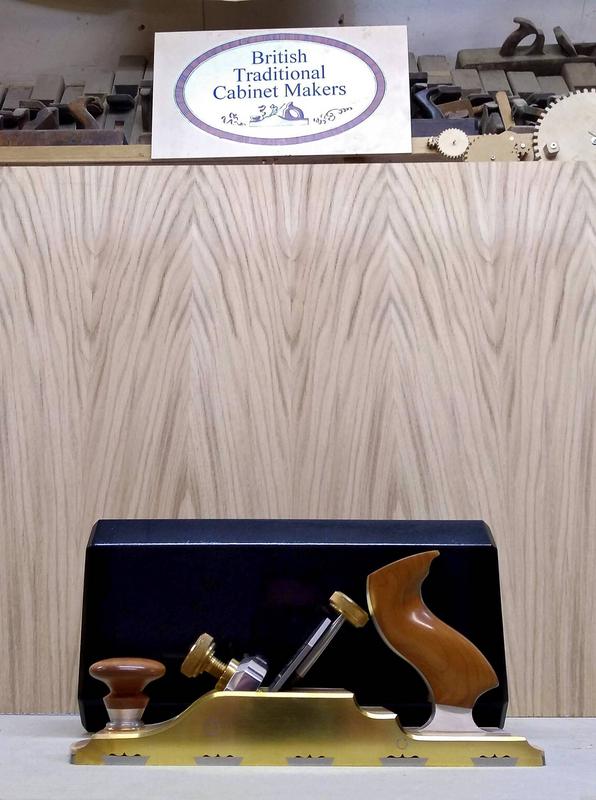

With the box complete I could add the finishing touches to the plane.

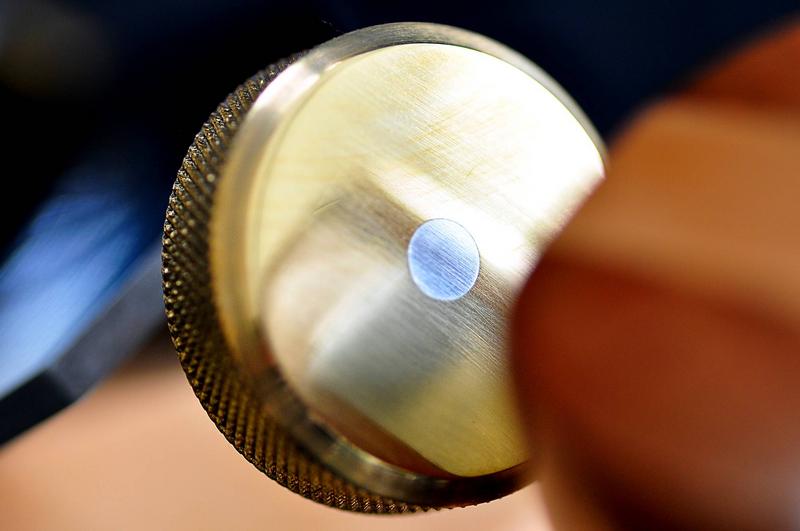

I started by making the brass collar to go under the front knob, this was purely for aesthetics as I thought the transition from cherry wood to aluminium to brass looked nicer.

I forgot to take pictures of this but here it is fitted to the plane.

Finally the plane was complete. I took a few hours to clean and wax every part before reassembling.

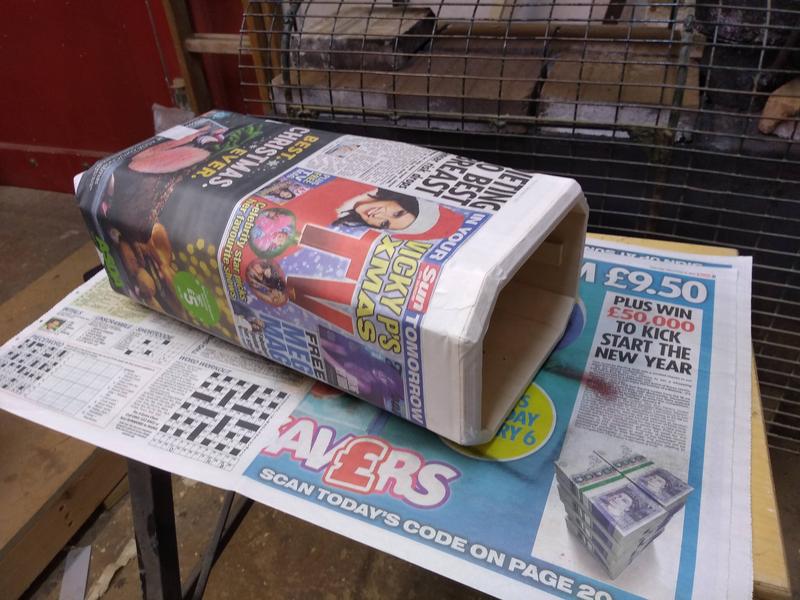

When I started this project I didn't realise how far it would take me. I've learnt so much along the way, so many new skills and techniques that I can develop further.

I've probably gotten more enjoyment from making this plane than I will using it, (if I use it!)

Its been the combination of 4 months in the making and over 100 hours work.

It's been quite the journey of late nights, hard work, concentration, patience and ups and downs.

I'd say I'm 90% happy with the end result, there are a few things which let it down but for a first attempt at a metal body plane it far exceeded my expectation.

I think it's important to constructively critique your own work and people have told me I'm my own worst enemy but the day I make something that's perfect is the day I've lost myself.

Thank you for all of the messages along the way, I really appreciate every one.

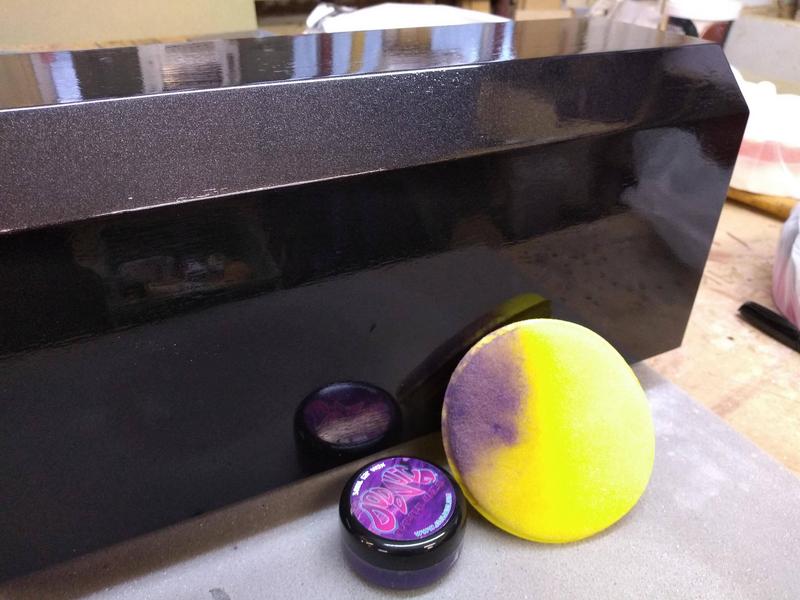

They say a picture is worth a thousand words so I'll stop my rambling now and just show the finished plane, there's a lot of pictures!

1

2

3

4

5

6

7

8

9

----------------------

10

11

12

13

14

15

16

17

18

19

----------------------

20

21

22

23

24

25

26

27

28

29

---------------------------

30

31

32

33

34

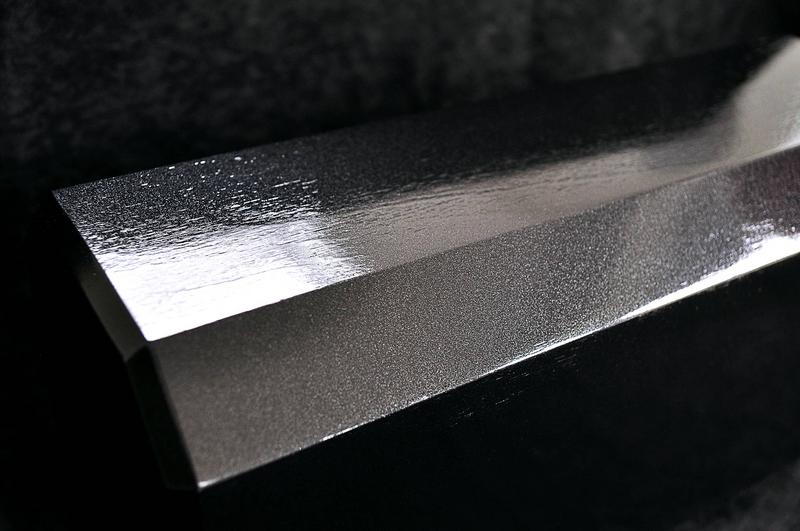

I hope you've enjoyed following the project as much as I have making it.

I'm going to miss having the evenings back to my self, won't know what to do!