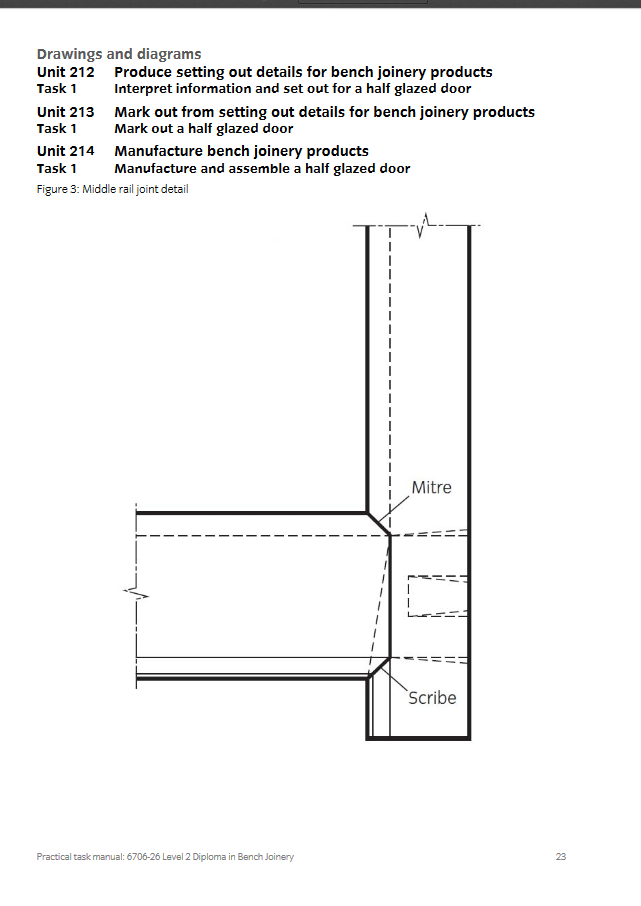

Thanks for your thoughts, both Doug71 and Jacob. When I looked at the picture I came to the conclusion that probably what was going on was what you've both described, i.e., essentially it was a means to bring together edge mouldings or treatments that either didn't match, or edge mouldings that ran only part way along a member's length, e.g., the inside edge of the stile, where there's a stopped chamfer above the lock rail, but a through chamfer below it (which is stopped above the bottom rail).

It all just seemed odd to me, and unlike Jacob, I don't think it's an attractive "little stylistic flourish ... showing off a bit of skill", rather the opposite, it being unattractive. But on that front, i.e., aesthetic attractiveness, there's nothing to to say my taste or preference is right and Jacob's is wrong.

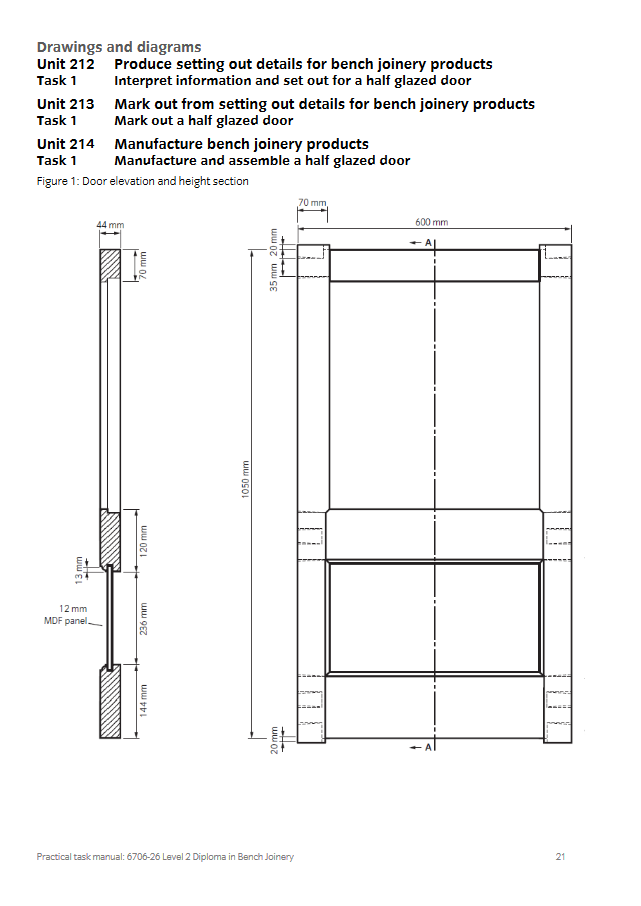

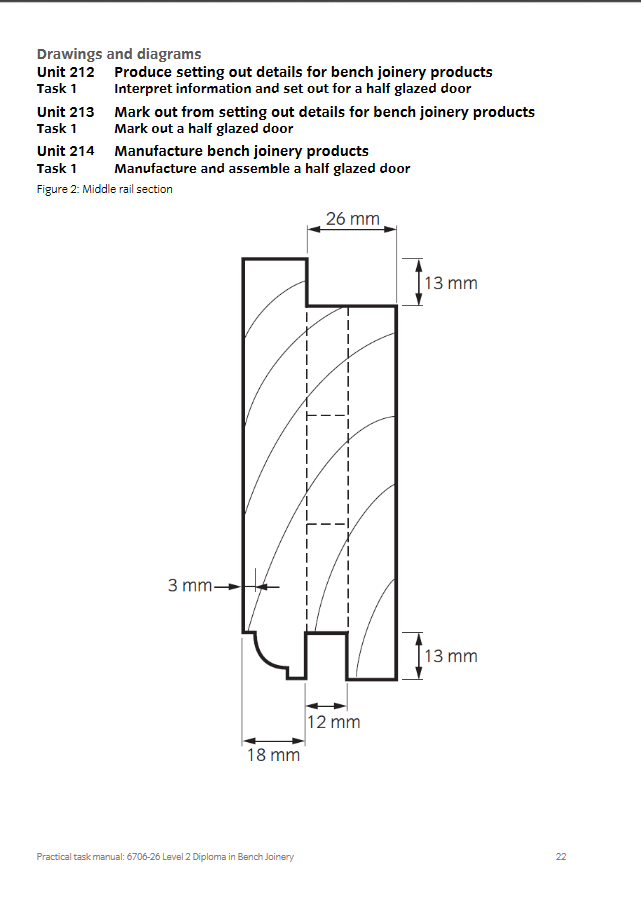

In reality, what most struck me when I looked at that photograph of the door in page 2 of this thread, was how similar the lock rail/stile intersection was in appearance to a similar exercise undertaken by bench joinery apprentices in their college based training. Over the last couple of years I've done some part-time teaching on both citb and C&G validated bench joinery courses at local colleges. In both cases the apprentices had to put together miniature architectural doors with what I could only describe as 'false diminished stile doors'. Again, the main reason seemed to be to make discordant edge mouldings or treatments, plus glass rebates come together. It all seemed a bit artificial to me, in the sense that I couldn't imagine anyone would really set out to make a door that gave a superficial appearance of being a diminished stile type, but actually wasn't.

In addition, it was all more difficult to execute than doing a real diminished stile door. I know that because for a bit of fun I had a go at doing both forms of joint in a miniature form, i.e., the citb false diminished stile, and a true diminishing stile ... the latter form was easier, and in my opinion, visually more attractive. In addition, made for a full architectural door, it would have increased the glazed area to let in more light, which I strongly suspect is the main reason for such a door pattern.

Anyway, I appreciate the thoughts of you both. Thanks. Slainte.