Hi folks,

I'm new in this section, so please forgive me if it's been asked before?

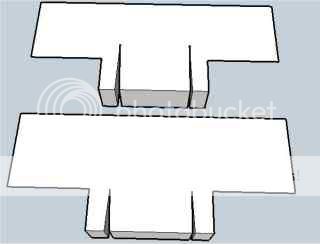

Is there a mathematical formula for positionig the kerf for a wedge, when cutting mortice & tenons? I'm currently planning a shelf / display unit, and drawing it in Sketchup, I'm not sure where to put the cut-out. I've not seen it mentioned in books, but looking at photo's of work done, it seems intuitive, or is that just "it looks good, 'cos a professional's done it"?

I was working on a 1:4:1 spacing - is that too much?

Overall length of mortice is 1 1/2", equal sided 'v' cut-out (should it slope to the 'outside'?), width & length (thickness of planks) 1/2", if that helps - not made any sawdust yet - so all help gratefully received before I ruin it...

I'll see if I can post a pic from sketchup on here in a bit.

Help! Thanks,

'Bvt

I'm new in this section, so please forgive me if it's been asked before?

Is there a mathematical formula for positionig the kerf for a wedge, when cutting mortice & tenons? I'm currently planning a shelf / display unit, and drawing it in Sketchup, I'm not sure where to put the cut-out. I've not seen it mentioned in books, but looking at photo's of work done, it seems intuitive, or is that just "it looks good, 'cos a professional's done it"?

I was working on a 1:4:1 spacing - is that too much?

Overall length of mortice is 1 1/2", equal sided 'v' cut-out (should it slope to the 'outside'?), width & length (thickness of planks) 1/2", if that helps - not made any sawdust yet - so all help gratefully received before I ruin it...

I'll see if I can post a pic from sketchup on here in a bit.

Help! Thanks,

'Bvt