devonwoody

Established Member

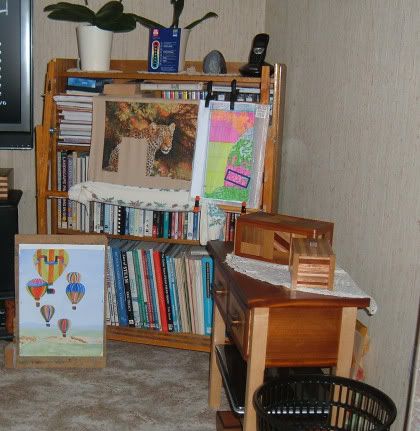

Tinytim, I suspect the boxes come out at around £3 in materials, so I suppose last year if I made forty boxes that's around £120. That makes it a very cheap hobby compared to other pursuits. I am retired so do not take part in any business activities.