devonwoody

Established Member

Started up in the workshop the past few days, like clearing the covers and old carpets of machine tables and pleased to say they have come through this winter well.

However, wooden tenon gauge as seized up, I shall bring it indoors to dry out.

I am now starting my fourth season using the same planer/thicknesser blade ( which was sharpened by Ian when he was Dragon saws) . Over those past years the blade did get a nick almost the first week but around the 9" from table edge so not a disaster and I can plane the nick out. The machine is the SIP 01332 model and that must now be seven years old with just one belt replaced. (it does rattle)

Prepared a piece of black walnut yesterday using the newish bandsaw and then used the thicknesser not the planer to clean up, and that will be OK for tissue boxes I hope.

Made a higher MDF fence for the B/Saw one that will hold in place with hand sprung clamps and I will make some wedges in case I get any drift when blade changing in the future. The fence idea came from a link I saw this week on the forum.

Got in mind making a tissue box in the pattern of a chess board (like L.Nibs the other week) but 12mm squares, any tips greatfully received.

Finished off the kitchen spatula stand complete with Asda tools for the daughter, it awaits a varnish when weather warms up. (its minus 2C in Paignton at the moment)

See ya.

However, wooden tenon gauge as seized up, I shall bring it indoors to dry out.

I am now starting my fourth season using the same planer/thicknesser blade ( which was sharpened by Ian when he was Dragon saws) . Over those past years the blade did get a nick almost the first week but around the 9" from table edge so not a disaster and I can plane the nick out. The machine is the SIP 01332 model and that must now be seven years old with just one belt replaced. (it does rattle)

Prepared a piece of black walnut yesterday using the newish bandsaw and then used the thicknesser not the planer to clean up, and that will be OK for tissue boxes I hope.

Made a higher MDF fence for the B/Saw one that will hold in place with hand sprung clamps and I will make some wedges in case I get any drift when blade changing in the future. The fence idea came from a link I saw this week on the forum.

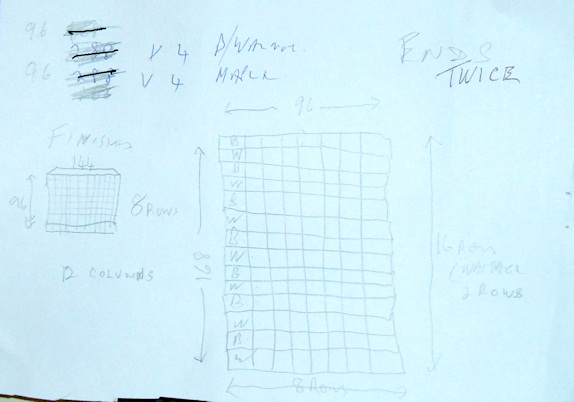

Got in mind making a tissue box in the pattern of a chess board (like L.Nibs the other week) but 12mm squares, any tips greatfully received.

Finished off the kitchen spatula stand complete with Asda tools for the daughter, it awaits a varnish when weather warms up. (its minus 2C in Paignton at the moment)

See ya.