DBT85

Established Member

Out of interest, why did you cut the tongue so thin?

You really did a great job! It's amazing how the right techniques and a little patience can make you do things you never thought of before. I recall watching his very first few youtube videos when I found them 6 months ago or so. He looked like a wizard. Cutting to lines. Things fitting. Sharp tools! And now you're doing it too (hammer)

BurnTheWitchAgain.gif

I'll have a think. I'm sure I've seen him do something about fitting one of these to the tail, I seem to recall him mentioning having to cut one of your braces short toallow the screw through so I must have seen a blog post or something. As to a second bench. Tish and guffaw! I've not even started my first yet!

Also just found this, some useful bits in there that you might like for your new bench. It's Sellers talking about finishing his off from 2015. little clips and hanging things and stuff to make it more ergonomic.

https://paulsellers.com/2015/01/closing ... -fitments/

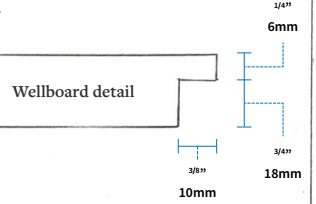

NickN":26drw4nb said:Yes, I did surprise myself, a LOT, actually, I thought it was going to be a complete nightmare disaster zone like my previous attempts at bodging have been, and somehow for the first time this all went together really well, even the trickiest bit, the sliding wellboard. I believe Mr Sellers uses an outdoor furniture oil of some sort but some of his benches have really darkened so perhaps he stains too - well, I don't mind mine staying light coloured, it's there to do a job ultimately.

I don't know that I'd want to fit two 52 1/2 vices to the bench, increases the footprint substantially if one on each side, and would get in the way if one each end of the same side, and the design doesn't end itself to that as a tail vice. I'd stick your working one on and leave it at that, restore the other and keep it for your next bench

You really did a great job! It's amazing how the right techniques and a little patience can make you do things you never thought of before. I recall watching his very first few youtube videos when I found them 6 months ago or so. He looked like a wizard. Cutting to lines. Things fitting. Sharp tools! And now you're doing it too (hammer)

BurnTheWitchAgain.gif

I'll have a think. I'm sure I've seen him do something about fitting one of these to the tail, I seem to recall him mentioning having to cut one of your braces short toallow the screw through so I must have seen a blog post or something. As to a second bench. Tish and guffaw! I've not even started my first yet!

Also just found this, some useful bits in there that you might like for your new bench. It's Sellers talking about finishing his off from 2015. little clips and hanging things and stuff to make it more ergonomic.

https://paulsellers.com/2015/01/closing ... -fitments/