I sometimes use the old door as a template too, but make sure you mark where it needs to be bigger than the original and also, if it has a leading edge planned on it, make sure you take that into account!

I fit a lot of reclaimed doors into old door frames.

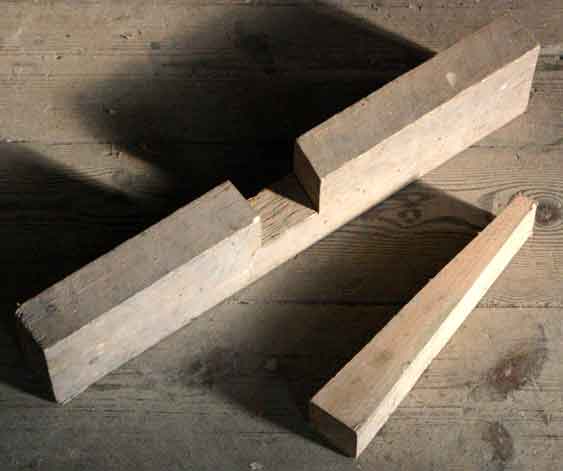

I like to make sure the stiles are equal, so measure the width at the top and bottom, (making sure it doesn't bow in or out too much) and then take the same amount of both side of the door so it is about 4 mm narrower than the frame. (I cut a leading edge with the saw at this stage)

I then stand it in the opening tight against the upright of the frame and mark along the bottom, parallel to the floor.

(This isn't the line to cut too) Measure how much height you need to remove in order to make the top rail the same width as the stiles and mark another line on the bottom of the door, parallel to the first line using this measurement and cut.

This should now be a perfect fit on both sides and bottom.

Then measure the height of the frame both sides, transfer this to the door minus about 8mm and cut.

Hopefully, you should now have a perfectly fitting door to hang.

Hopefully that all made sense!