Time to start work on the rendering of the porch. For a start, all of the Savolit panels were sitting loose in rebates, deliberately, because I wanted to do a little lead detail at the bottom. Here's the lead:

And here is the bottom of a panel:

The panel at the bottom sits in front of an upstand, designed to have the lead between the two. It's easier to show a photo than explain. Inside first, then outside:

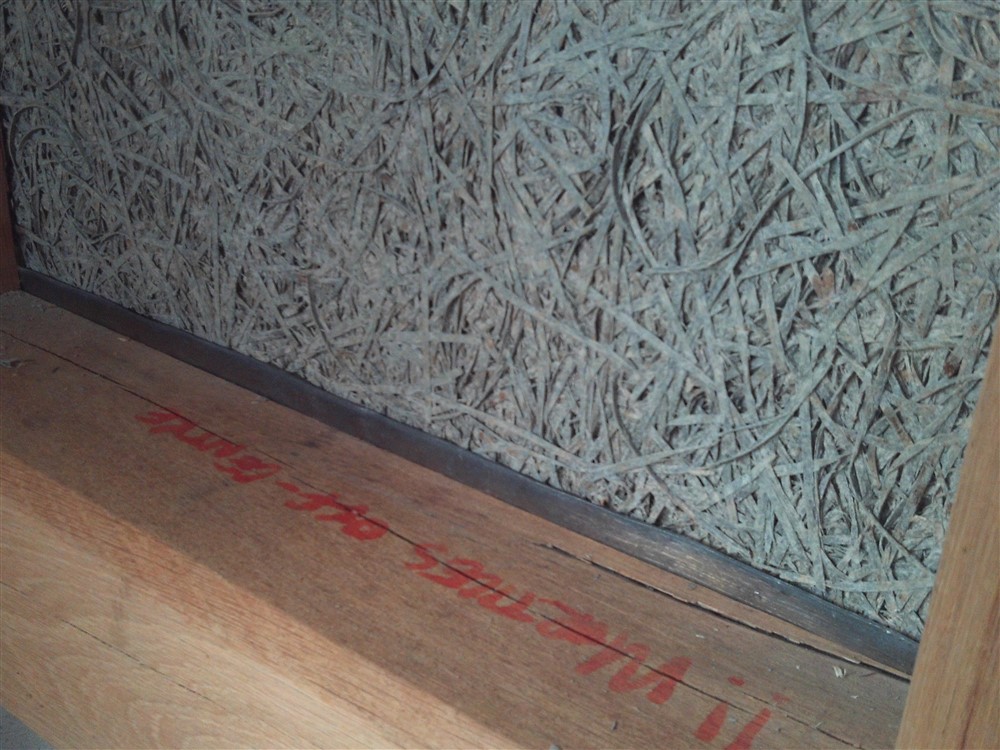

Here is a view into the side rebate, with the board fixed back properly in position. This shows the strategy with these render panels, which is to allow for movement and shrinkage in the oak framing. The render will squeeze into the rest of the rebate, meaning that even if the oak frame shrinks considerably there will be no path into the structure for water (or light, for that matter):

I taped up the oak with Duck tape because masking tape is porous enough that it doesn't prevent the lime from immediately discolouring the oak. There is an immediate and dramatic reaction between lime render (and cement, too) and green oak, leading to permanent discolouration. Anyway, I was now ready for render:

The render depth is about 30mm here, which is a lot. So, I am going to build it up in two layers. Here is the first coat, called a scratch coats because it gets scratched to form a key for the second coat:

Oh, and as a fun little aside, you know how it is when you knock something together quickly as a temporary measure just to get yourself out of an immediate problem? Well, those things, in my experience, usually hang around for at least 30 years. Here is my plasterer's hawk, made decades ago for 5 minutes of plastering, and still going strong (= as badly as ever):