You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting a square tenon on the end of a round dowel

- Thread starter Bodgers

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

peter-harrison

Established Member

What I do for things like this is to cut a square piece of scrap, whose faces are as long as the diameter of the rod. Stick it on the end of the rod using superglue. Use the square as your reference against fences etc. When the work is done, cut it off.

Bodgers

Established Member

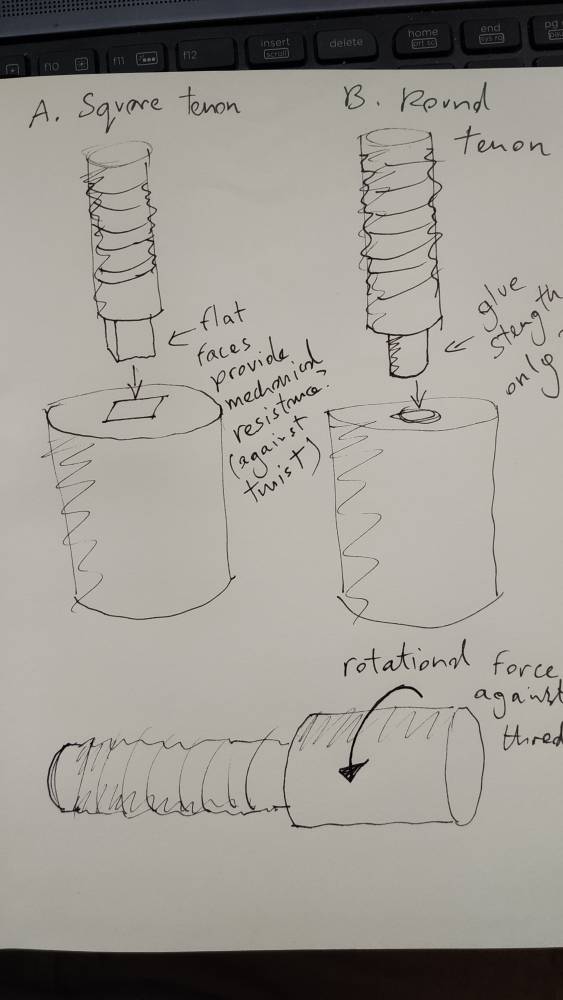

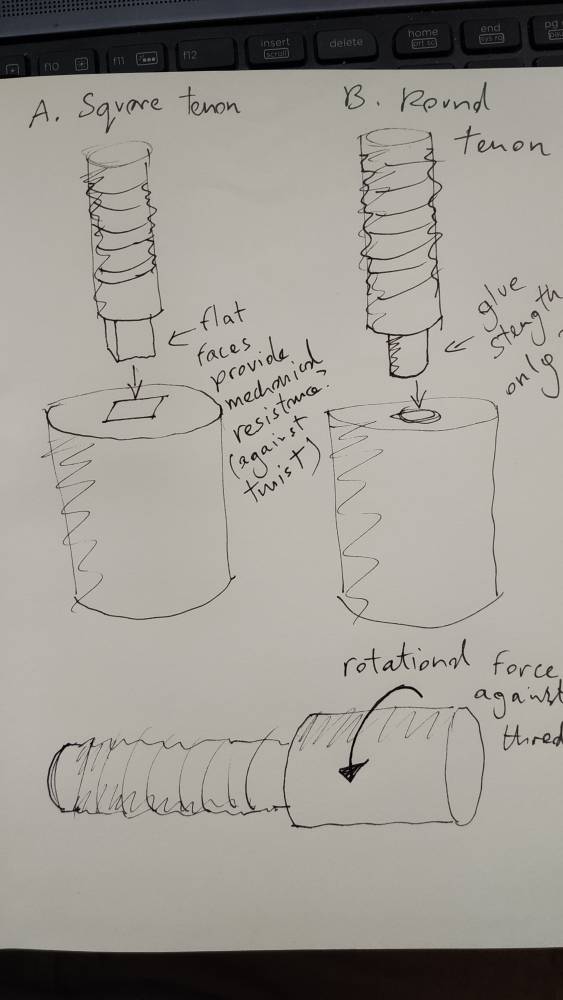

Out of curiosity I posted the question on Lumberjocks with the following sketch. Consensus seemed to tend towards the square tenon

Sent from my Redmi Note 5 using Tapatalk

Sent from my Redmi Note 5 using Tapatalk

Bodgers

Established Member

Mine is probably somewhere between the two 38mm to 60mm dowels. Not sure if that makes much difference.sunnybob":3qluvrpz said:look at the distance between the corners of the square to the outside of the round on the sketch, then on the picture posted.

The sketch shows at least twice as much wood than the pic.

The weakness of the joint is in the distance between the corner and the diameter. Ignore the thickness of the square, imagine how much (or how little) force it would need to split that amount of wood, using a twisting lever as long as the cross bar youre fitting.

If this is a vice handle, then the first time you need to lean on it that amount of wood will give way. If this were made of metal, then it would be impossible to break, but made of wood.....

If this is a vice handle, then the first time you need to lean on it that amount of wood will give way. If this were made of metal, then it would be impossible to break, but made of wood.....

Bodgers

Established Member

sunnybob":30na9opb said:The weakness of the joint is in the distance between the corner and the diameter. Ignore the thickness of the square, imagine how much (or how little) force it would need to split that amount of wood, using a twisting lever as long as the cross bar youre fitting.

If this is a vice handle, then the first time you need to lean on it that amount of wood will give way. If this were made of metal, then it would be impossible to break, but made of wood.....

By making the tenon longer and the mortise deeper should resolve that. I think that would be the same issue with the round tenon as well.

Phil Pascoe

Established Member

Except you would not have four weak spots with a round tenon. Any stress/weakness would be on the the circumference (the whole glued area) and not the four corners outwards.

Bodgers

Established Member

I see what you mean there. But...if you think of the joint without any glue in it, the failure is immediate on the round tenon version as it would just slip around.phil.p":2a1fr91y said:Except you would not have four weak spots with a round tenon. Any stress/weakness would be on the the circumference (the whole glued area) and not the four corners outwards.

The break on the square corners on the square version suggests the mechanical resistance that it offers breaks before the glue. And if that's the case the round tenon has no mechanical resistance so would fail instantly.

Sent from my Redmi Note 5 using Tapatalk

Bodgers

Established Member

I was just surprised by the initial comment/observation that's all, and genuinely interested in why. That's why I asked the same question on Lumberjocks (and got the opposite answer)sunnybob":30kyb8sb said:I think we've spent enough time trying to convince you.

its your work, do what you will.

We wont say "we told you so"

honest.

As I say, it is already done now, although I will extend the depth.

Sent from my Redmi Note 5 using Tapatalk

Similar threads

- Replies

- 44

- Views

- 5K

- Replies

- 8

- Views

- 2K

- Replies

- 20

- Views

- 3K