Bodgers

Established Member

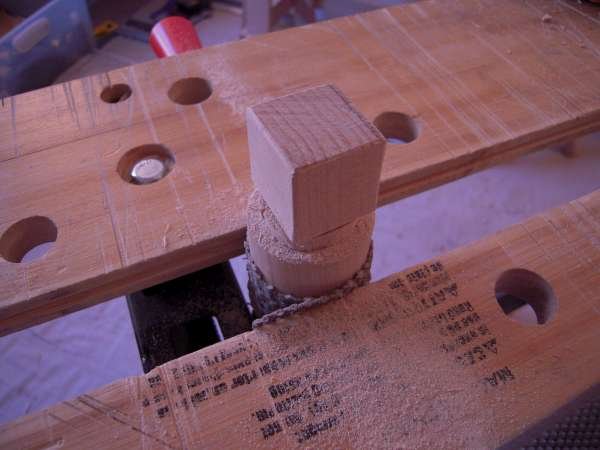

I need to mortise a 38mm dowel into the end of a 60mm dowel.

The 60mm dowel will be the 'head' end of a large wood screw with a handle drilled through it.

Any ideas on how to accurately scribe a proper square on to the end on the dowel? I have used a combination square to attempt it, but I don't seem to be able to get the lengths of the sides correct. Hard to explain. Is there a jig for this?

I could just drill a round hole into the 60mm dowel and push it in, but I don't have a 38mm forstner, and there will be a fair amount of twisting force and I want to have some mechanical connection.

Sent from my Redmi Note 5 using Tapatalk

The 60mm dowel will be the 'head' end of a large wood screw with a handle drilled through it.

Any ideas on how to accurately scribe a proper square on to the end on the dowel? I have used a combination square to attempt it, but I don't seem to be able to get the lengths of the sides correct. Hard to explain. Is there a jig for this?

I could just drill a round hole into the 60mm dowel and push it in, but I don't have a 38mm forstner, and there will be a fair amount of twisting force and I want to have some mechanical connection.

Sent from my Redmi Note 5 using Tapatalk