We left off last time with the drawers completed - coplaner with one another, and then finished in white shellac (Ubeaut).

It was was nice to work at a relaxed pace this weekend, since the goal was to install the drawer handles, wax the drawers (Renaissance), and complete the rear of the carcase. All nice and easy.

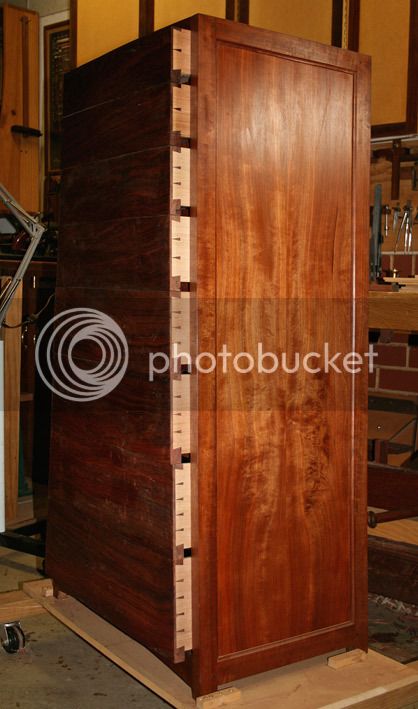

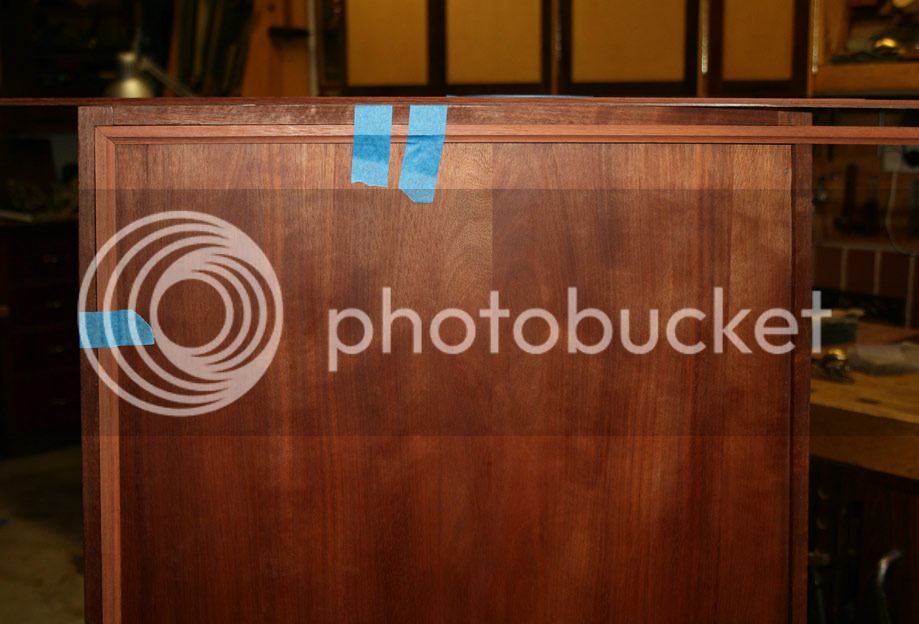

The panel for the rear is 1/4" thick Makore, as are the carcase frame-and-panel sides. I made the panel at the start of the build. It had begun as one of the side panels, but it lacked any figure, and consequently I set it aside for the rear of the carcase. This was finished inside with wax and outside with Livos Universal Wood Oil (an Aussie product), which was used on the all the other parts of the carcase.

The panel is secured with nails into the frame. The panel can move laterally via widened (drilled) nail holes. There is a coved attached moulding that tidies up the fitting. The cove matches the cove that is part of the frame-and-panel sides (which were shaped into the frames).

I got to use my restored mitrebox

Before the rear could be done, the handles needed to be attached to the drawers. The handles had been a major headache for a long time. I knew what I wanted but could not find ready-made versions. I hunted everywhere like an obsessed dervish!. I was about to build them in Jarrah (my wife's choice to go with the Jarrah drawer fronts) when I found them about 6 weeks ago on eBay! According to the advert they are "antique bronze".

After building a template, and carefully marking, triple checking measurements, I drilled the holes and screwed them on ...

What do you think?

Here is a side. The bow is very subtle, softening the profile ...

What's there to do? Well, I am starting on the top section. The chest needs a crown moulding. This will hide a lid. Raising the lid will reveal a mirror on the underside, plus a recess to place jewellery or cosmetics. The recess will be leather lined.

Then there are jewellery trays to fit (also leather lined). This will go in the top drawer ..

All the drawers have good extension, held horizontal by the last 1 1/2" -2".

Until the top is done ...

Regards from Perth

Derek