Before I get in to the troubles I'm experiencing with the lid supports I bought from Rockler, here's where I am in terms of progress. I haven't had much time on this at all lately; believe it or not, I've been working for most of the past two-weeks :shock: (though, technically, I'm still unemployed! :roll: :wink

!

Bits of sealing and staining here and there. I bought the acrylic lacquer from Yandles last Saturday but instead opted for the melamine lacquer, purchased at the same time. Lid has now had a couple of coats and the finish is building up well. Still needs some more work.

When I was staining the top, I thought I'd be clever and try to save space by using the carcase as a 'finishing bench'... A scrap of ply went on top to protect it - it was plenty wide enough but, about 2" short... Anyway, after the photograph below, you can see why I ended up scraping off this layer and re-staining it! :x

The base has been given a couple of coats of beeswax and it's come out quite nicely. That's now fixed in place and there's nothing more to be done, there!

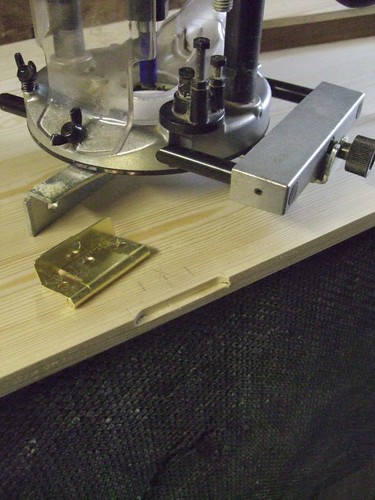

Today, I wanted to crack on and get those hinges fitted. I started by screwing them directly to the underside of the top (no recess). Then, I could centralise the middle one, chop out the waste and from that, mark out and chop the other two in to the back rail.

A scrap of MDF here prevents breakout. :wink:

This part went well and, I'm very pleased to say, the hinges sunk in neatly first time. 8)

However, I've wasted several hours this afternoon fiddling with and re-positioning

these lid supports from Rockler. I've been following the

instructions, working off the pivot point of the hinges but, I just can't get them to work without lifting the hinges, as this next photo' will show:

Thank God I only used short screws to hold these in place - had I found any longer ones, I'd have ripped the back rail to shreds by now!! :shock: My first reaction was that I'd miscalculated and bought the wrong ones; there felt like an awful lot of resistance, until I realised what was happening with the hinges... :? :x

I'm using the side-mounted hinges. Perhaps I would've been better off with two back-mounted ones? Could it be the hinges; should I have stuck with butt hinges?

I can see the appeal of using these

Cranked Hinges; I can fold the lid right back to 180° before it feels as though something wants to give. If it's any consolation, these lid supports do appear to work - I've only got one fitted here and there's no hint of any strain or struggle.

I really don't know what to do right now and would greatly appreciate any advice.