I picked up my latest Axminster delivery from the Post Office on Saturday morning Plenty of sanding sheets, some more stain and, er, that spare set of knives for my planer I've been meaning to buy for over a year now!

After a couple of hours sanding on Saturday, I'm pleased to report that the velcro-backed sheets from Hermes held on very well. I still managed to get through three of them at 80g but, they've got more stamina than the aluminium oxide stuff, that's for sure.

I then a applied a thin coat of sanding sealer (50/50 with thinners) to each board and the inside edges of the frame components. Got back in to it today and spent another couple of hours applying a coat of Mid Oak stain, after Pete and SWMBO's confirmation. :wink:

(That white MDF box/cupboard is another job I'm doing for someone else...)

This second shot will show you just how stuffed I am when it comes to finding space in my workshop to let things dry! I wasn't able to do any other work around it.

Fortunately though, this stuff dries within ten minutes, just like they said it would.

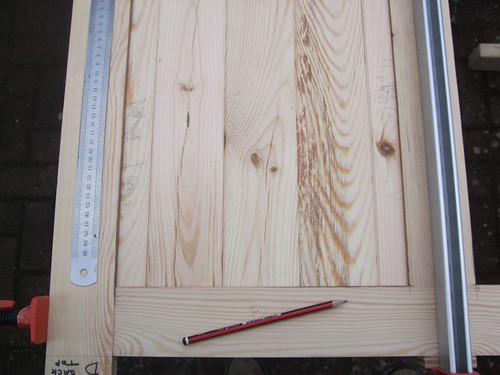

Oh! This is how the boards join together with the chamfers, if I haven't shown you already... I've hand-planed 1mm off the tongues to allow for movement (and, to ensure a tight fit on the face side :wink

.

What I didn't realise until I'd already started staining was that my sander had left some tiny little swirls on the surface which weren't visible before. :shock: They're not noticeable unless you get

really close. There are a couple of scratch marks too. Hopefully, I'll be able to hide the worst offenders round the back... Sorry about this Pete; it's probably not as bad as it sounds but, I hope it doesn't cause you any bother...

I probably did get a little carried away with that 80 grit paper - there was plenty of evidence to show that my planers knives aren't in great nick (

no pun intended! :shock

and the boards aren't as tight a fit in the grooves as they were fresh out of the thicknesser.

Knotting came next and was applied to all the dead knots. I almost made the mistake of applying this

before the stain - until I read the label on the side of the bottle; that's not what you're supposed to do! :roll:

I guess it would show through if you applied the knotting first? Anyway, it's looking pretty good, if I do say so myself.

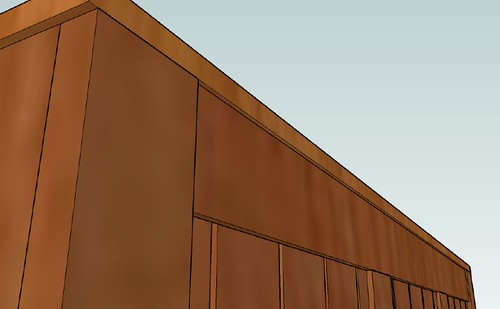

I'll apply a final coat of sanding sealer tomorrow. I won't be waxing all the boards as I did with the samples. I'll wax the top and maybe the outside faces of the frame... Otherwise, I'll never get this done!! :wink: