Late to the party, only just seen this post, sorry.

As a Brit living in Switzerland (and with a Swiss wife) German is my 2nd language, used daily, so perhaps this can illuminate the previous posts a little more.

Basically the previous posters have got it right but a couple of clarifications:

1. Fohren (as someone said, there's an umlaut over the O so it should be written FOEHREN on a keyboard such as English, without umlauts) - this is simply the name of the place where it's made and shouldn't be translated (any more than one should try to translate, say, Manchester into German). The clue is in the "D-54343" - this is the postcode and in most of mainland Europe the postcode is placed before the name of the town. The "D" means Germany ("F" is for France, "B" is for Belgium, etc, etc).

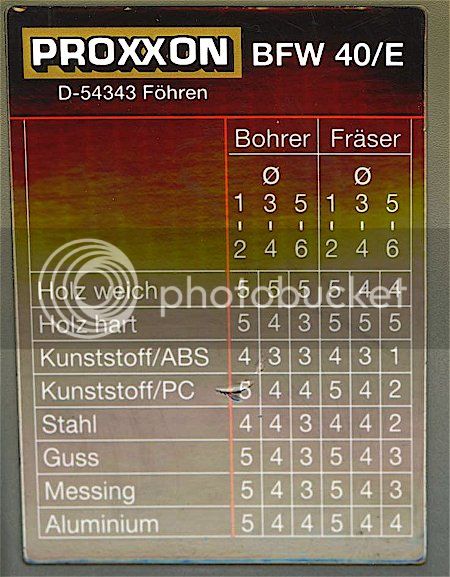

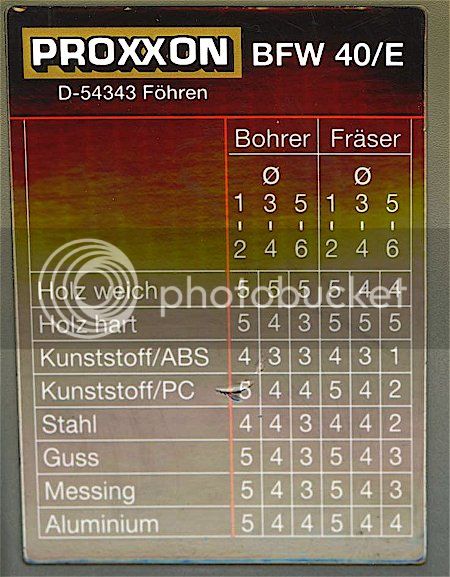

2. The tool in question is listed on the Proxxon site as a "complete integrated workcentre" capable of both drilling/boring & milling/routing. It's electronically controlled between 900 & 6,000 rpm. It runs on 40V transformer and has collet chucks to handle tools & drills with 2.35 to 3.0; 3.2 to 4.0; 4.0 to 5.0; and 6.0 mm diameter shanks. There's the clue(s), so although as someone pointed out "Bohren" could mean auger, in this case is simply means drilling (the machine can be used for both drilling and milling/routing). And there's the 2nd clue, the dataplate is simply showing speed ranges when either drilling (LH column on plate) or milling/routing (RH column). The different speeds are Proxxon's suggestions according to the material being worked and the shank diameter of the tool being used.

3. The lists of materials already provided are quite correct, the only thing I would add is that in normal German engineering usage "Guss" only means cast iron (as somone has said, the word simply means cast, but funnily enough I've never heard, say, cast aluminium or cast brass referred to as "Guss" - only cast iron. The above 2 examples are always referred to in German as "Alu Guss" or "Messing Guss" respectively. Don't ask me why, but 'tis so.

4. As someone has already said I think, this is not a "normal size" dril/mill machine. I don't have this machine but a few other Proxxon bits and pieces and although looking somewhat "toy like", other Proxxon kit suggests to me that if someone needs highly accurate drilling and milling (or routing) on small bits and pieces, such as for clocks or small models for example, then this machine would be a very good buy - though no doubt rather expensive. From the website I also note that the table for X and Y axis movements is a separate purchase (ref KT 150, made of "Alu Druckguss" - i.e. pressure die cast aluminum).

HTH

Krgds

AES