Rhyolith

Established Member

This a guide aimed to help those who frequent car boots, antiques markets and eBay to pick out the best hand drills.

Things to check:

This section provides an overview of across the board issues and ailments the plague second hand hand drills.

Firstly

Always give the handle a turn, you can tell a lot from how smooth it goes round; obviously take into account rust and dirt... these can usually be easily removed.

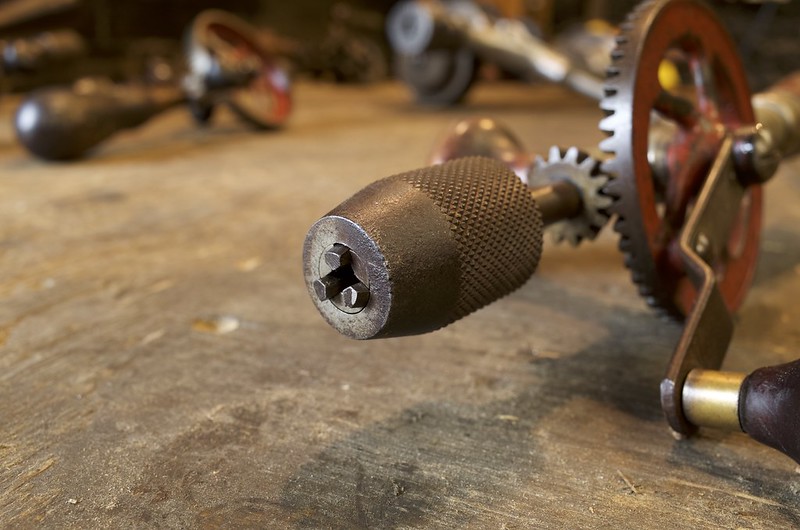

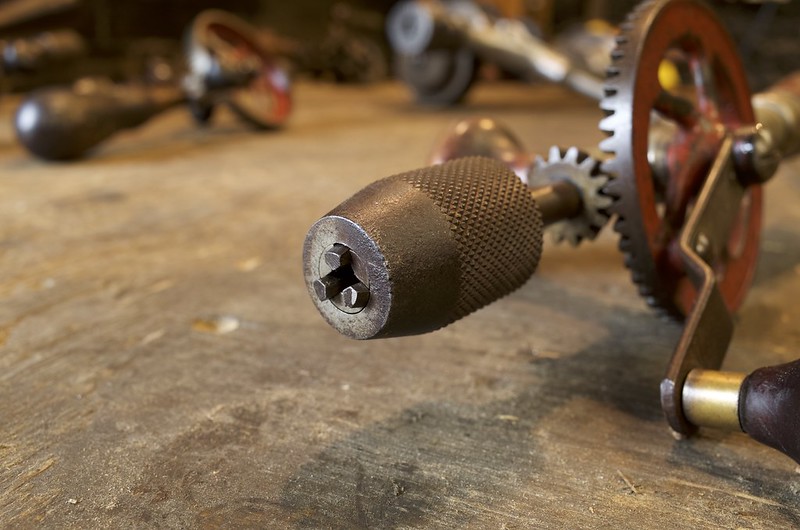

Chuck springs

It is quite common for the springs in the chuck to be bent or otherwise damaged, even outright missing. Check this by seeing if all the jaws line and open up as they should, it is quite obvious when something is wrong (look at example below).

A chuck with bad springs

Very damaged/Missing Springs by Rhyolith, on Flickr

Very damaged/Missing Springs by Rhyolith, on Flickr

A chuck with good springs

Un-damaged Springs by Rhyolith, on Flickr

Un-damaged Springs by Rhyolith, on Flickr

The best way around this is to buy drills with springless or protected spring chucks, these very rarely require more than a clean to get working well.

Protected Spring Chuck by Rhyolith, on Flickr

Protected Spring Chuck by Rhyolith, on Flickr

Side Handle

Whether or not a missing side handle is an issue depends very much on the model of drill and what your going to use it for. Functionally a breast drill (or a drill your going to use as a breast drill) should have a side handle, this basically means most large hand drills (minus pillar/bench drills). For smaller drills it matters far less and many of the smallest models never had one to start with.

For collectors the drills are worth a lot more with there original side handles, so if you want your investment to hold its value (only really an issue with expensive models) then this is worth thinking about.

An example of a drill with a side handle. In nearly all cases they are attached via a machine thread in order for easy removal (for transport/to fit into difficult spaces).

Millers Falls No.120B by Rhyolith, on Flickr

Millers Falls No.120B by Rhyolith, on Flickr

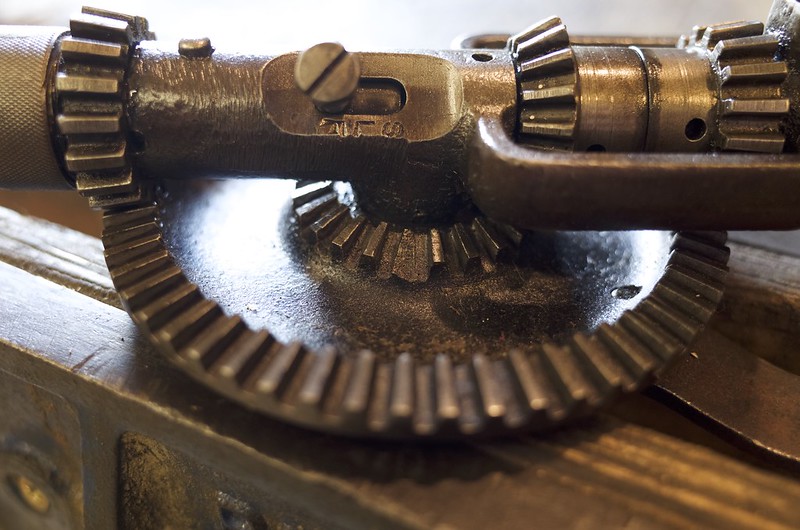

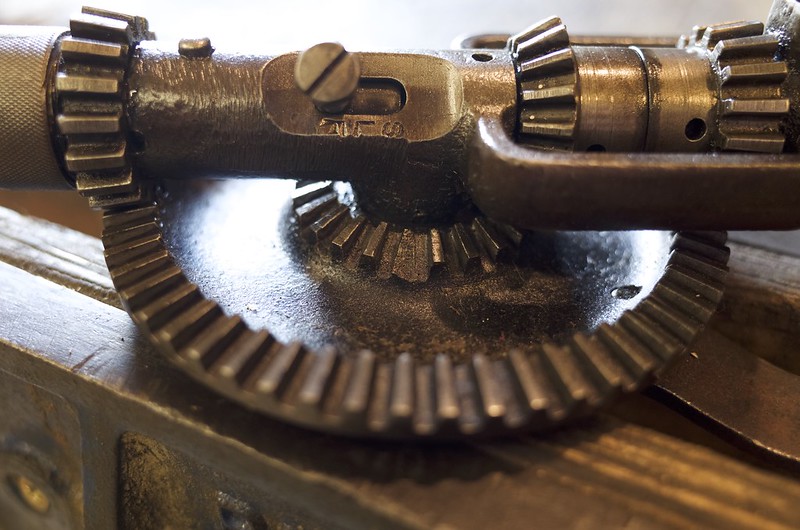

Gear Teeth

Worn teeth are hard to spot if you don't know what un-worn teeth look like, so here is an example of worn and un-worn teeth on two drills of the same model.

Worn Cogs by Rhyolith, on Flickr

Worn Cogs by Rhyolith, on Flickr

Un-worn Cogs by Rhyolith, on Flickr

Un-worn Cogs by Rhyolith, on Flickr

Worn teeth are also a pretty good sign that the drill has been either used a lot or abused in its past, so worth steering clear of.

Missing gear teeth are generally easier to spot, just give the handle a couple of turns and check all the gears carefully. Completely missing teeth (such as below) are a problem, however partially missing or chipped teeth (such as below also) are not so long as there are not too many of them (too many probably means there is an issue with the metal on the gears). North Brothers "Yankee" Drills are particular prone to losing teeth on all their gears, but its worth checking on all makes and models.

Completely missing

Missing Cog/tooth by Rhyolith, on Flickr

Missing Cog/tooth by Rhyolith, on Flickr

Partially missing/chipped

Partially Missing cog/tooth by Rhyolith, on Flickr

Partially Missing cog/tooth by Rhyolith, on Flickr

Play Main Gear

This is a more subtle issue that is not always apparent from a simple turn of the handle, so its worth testing for specifically. It commonly effects most models of hand drills in the main drive gear (one with the crank). This play can make an otherwise flawless drill run horribly roughly or jam when put under load (drilling). How I check is shown in the videos below (click on images to play videos):

A drill with too much play:

Yankee No.1545 with too much play by Rhyolith, on Flickr

Yankee No.1545 with too much play by Rhyolith, on Flickr

A drill with an acceptable amount of play:

Yankee No.1555 with acceptable play by Rhyolith, on Flickr

Yankee No.1555 with acceptable play by Rhyolith, on Flickr

A a drill as close to perfect as you can expect to find:

Millers Falls no.97 with nearly no play by Rhyolith, on Flickr

Millers Falls no.97 with nearly no play by Rhyolith, on Flickr

Design Features

This section gives an overview of the more different designs and mechanisms in order to help you choose drills suitable for your needs

Chucks

Chucks are important, they often determine what a drill can be used for. The most common varianty in hand drills is the "Standard Spring" in which the jaws fitted together with 3 coiled springs in a triangular shape, these are very prone to getting damaged and there are alternatives:

First is McCoy's springless, found on several smaller Millers Falls Models such as the example from a Millers Falls No.3 below. These chucks have and addictively smooth motion and are moderately common on Millers Falls Nos.1,3 & 5 (sometimes on No.2s, but rare). Their main weakness is that the jaws do not pull back automatically when the chuck is loosened so you either have to push them in yourself or turn the drill upward and let gravity do it, its not a major problem but does add to the faff factor. So these are great if your not bothered about working quickly.

McCoy's Springless Chuck (Millers Falls No.3) by Rhyolith, on Flickr

McCoy's Springless Chuck (Millers Falls No.3) by Rhyolith, on Flickr

The Jacobs provides an unparalleled firm grip at the cost of having a chuck key to faff about with (and loose). These are good on drills that never leave the workshop, as then the issue of the chuck key is that much less annoying. Also the chucks firm grip makes it ideal for large drills, though few large hand powered drills have Jacobs.

The Modern Keyless Chuck is possibly the best all round, but only the footprint drills seem to have it (such as the example below). Most will be familiar with these as they are pretty much the norm for modern cordless electric drills.

Modern Keyless Chuck (Footprint Hand Drill) by Rhyolith, on Flickr

Modern Keyless Chuck (Footprint Hand Drill) by Rhyolith, on Flickr

Protected Spring Chuck is essential a standard spring chuck without the same reliability issues (illustration in the "chuck springs section). They are pretty standard on many higher grade models, with many models from Stanley, North Bros, Millers Falls, Record and SIF having them. Two common variants for small drills listed here:

Stanley small hand drill variant (more or less identical to Record, SIF, some Millers Falls and North Brothers variants)

Protected Spring Chuck (Stanley No.803) by Rhyolith, on Flickr

Protected Spring Chuck (Stanley No.803) by Rhyolith, on Flickr

The North Brothers "Yankee" Variant, this is used on more or less all North Bros Drills (only the size varies).

Protected Spring Chuck (Yankee No.1430) by Rhyolith, on Flickr

Protected Spring Chuck (Yankee No.1430) by Rhyolith, on Flickr

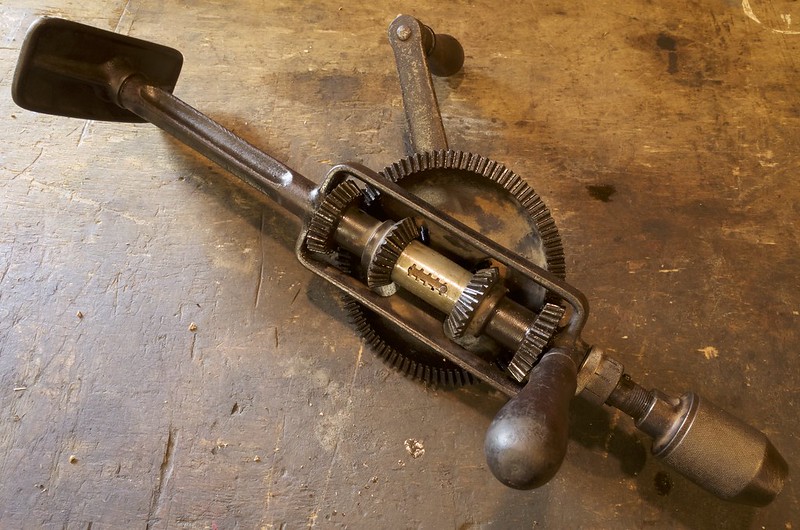

How many pinions?

Most hand drills will have Between one and two pinions, with some more sophisticated models have 3 or 4. Generally 2 pinions are better as the idler pinion supports the main crank gear keeping it in engagement which his a particular advantage under heavier loads, this also applies to most with more than 2.

Single Pinion Hand Drill

Stanley No.805 by Rhyolith, on Flickr

Stanley No.805 by Rhyolith, on Flickr

Two Pinion Hand Drill

Millers Falls No.2 (2 Pinion Model) by Rhyolith, on Flickr

Millers Falls No.2 (2 Pinion Model) by Rhyolith, on Flickr

Three Pinion Hand Drill

North Brothers "Yankee" No.1445 by Rhyolith, on Flickr

North Brothers "Yankee" No.1445 by Rhyolith, on Flickr

Four Pinion Hand Drill

Millers Falls No.97 by Rhyolith, on Flickr

Millers Falls No.97 by Rhyolith, on Flickr

Generally speaking single pinion drills are great for low load tasks (drilling small holes) due to the reduction in friction from only having one pinion. However under heavier load these one pinion designs struggle with the gears wanting to pop out of their mesh, meaning all but the smallest good hand drills will have more than 1-pinion or an Equaliser.

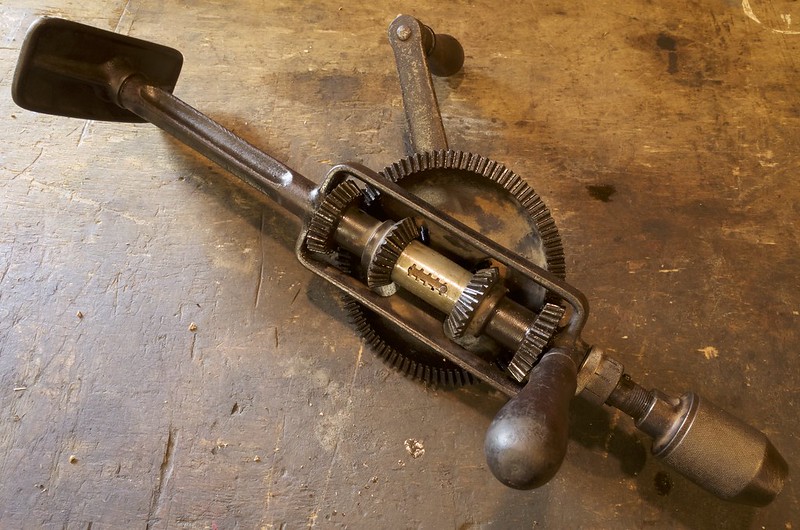

Equalisers

Equalisers are and alternative method of supporting the main crank gear that is generally superior to a second pinion, as it achieves the same thing with less friction and play. Equalisers also tend to support the gear more firmly than a second pinion and don't have as bad a rasping effect under heavy load, if any at all.

The Millers Falls No.2 was produced in both 2-pinion and equaliser variants over its long production life, making it an excellent example of the superiority of equalisers. Though both models of the No.2 are un-doubtable excellent, the equaliser model is just that bit smoother, particularly under heavy load. See the mechanisms of both here:

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

Other Equaliser variants are generally not as effective as the No.2's roller, but still better than a second pinion:

Goodall Pratt No.5 1/2 Equaliser by Rhyolith, on Flickr

Goodall Pratt No.5 1/2 Equaliser by Rhyolith, on Flickr

Equaliser Pin Millers Falls No.200 by Rhyolith, on Flickr

Equaliser Pin Millers Falls No.200 by Rhyolith, on Flickr

Equalisers are more or less unique to higher quality drills, so if you holding a model with an equaliser than its probably a good drill.

Ratchets, Bells and Whistles

There are a number of models out there with more sophisticated mechanisms to control the torque and allow drilling in difficult places.

The most common are in-bulit ways of changing gear that means a lower or higher gear can be engaged without having the remove the drill from the work. Often found on premium breast drills these mechanisms are highly desirable and a sign that the drill was a premium model in its day (so good quality).

This Yankee No.1445 has a switch on the main frame that allows the gears to be changed.

North Brothers "Yankee" No.1445 by Rhyolith, on Flickr

North Brothers "Yankee" No.1445 by Rhyolith, on Flickr

Ratchets are rarer and perhaps less useful, made for the more specialised task of allowing drilling in tight spaces.

Millers Falls No.200 has a basic ratchet similar to a ratcheting wrench

Ratchet mechanism Millers Falls No.200 by Rhyolith, on Flickr

Ratchet mechanism Millers Falls No.200 by Rhyolith, on Flickr

Double Ratchets essentially for fill the same purpose as standard ratchets, but are more efficient as the drive is in both directions (forward and backward cranks), these mechanisms are only found on a handful of models and are highly sought after... mainly because they are awesome!

This North Bros No.1530 can use its selection of ratchets and tiny size to work in very tight spaces.

North Brothers "Yankee" No.1530 by Rhyolith, on Flickr

North Brothers "Yankee" No.1530 by Rhyolith, on Flickr

Of course with a select few models the companies decided to go all out then you get the North Bros "Yankee" No.1555 and Millers Falls No.97

North Brothers "Yankee" No.1555 by Rhyolith, on Flickr

North Brothers "Yankee" No.1555 by Rhyolith, on Flickr

Millers Falls No.97 by Rhyolith, on Flickr

Millers Falls No.97 by Rhyolith, on Flickr

Generally the models with ratchets and gear changes are sort after and expensive. Functionally the 2-gear mechanisms are more useful, particularly on large drills. The ratchets come into there own in fairly specific situations (tight, but no too tight spaces) and are more useful to most modern users on a small drills for cabinet making etc.

Adjustable Handles

There are a small number of models with specialised or adjustable handles. As these are fairly individually unique, so I will just put pictures here. They are generally geared towards fitting into tight spaces or personal preference of how to hold a drill.

Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr

Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr

Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr

Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr

Record No.125 "Improved" by Rhyolith, on Flickr

Record No.125 "Improved" by Rhyolith, on Flickr

Record No.125 "Improved" by Rhyolith, on Flickr

Record No.125 "Improved" by Rhyolith, on Flickr

Footprint Hand/Breast Drill by Rhyolith, on Flickr

Footprint Hand/Breast Drill by Rhyolith, on Flickr

Leytool Drill by Rhyolith, on Flickr

Leytool Drill by Rhyolith, on Flickr

Proto Hand Drill by Rhyolith, on Flickr

Proto Hand Drill by Rhyolith, on Flickr

Makes & Models

You can spend a long time looking up the best makes and models, which is worth it if you really want "the best" however for the sake of a short guide here is a list of makes that are more or less universally good quality.

- Millers Falls

- North Brothers "Yankee" (Look out for damaged teeth)

- Goodell Pratt (linked to Millers Falls

- Record

- SIF (Suffolk Iron Foundry)

- Leytool

- Metabo

I did not include Stanley because although they made some very good drills, they also made some of the worst ones I know of (mostly the newer models), so it being a Stanley is no guarantee of quality.

Here is a list of my Entire collection: https://www.flickr.com/photos/123749911 ... 6820616314, I try to review every single one and am adding more drills and info all the time. Its a good place to start if you want more info on makes and models and how they perform (there is plenty of info on the net too, especially for the big 3 American companies (North Bros, Millers Falls, Goodell pratt).

Makes and Models Links:

Millers Falls & Goodell Pratt: http://oldtoolheaven.com

Goodall Pratt 1926 Catalog: http://www.blackburntools.com/articles/ ... -no-16.pdf

North Brothers 1931 Catalog: http://www.blackburntools.com/articles/ ... yankee.pdf

Record Drills (scroll down): http://www.recordhandplanes.com/rare.html

I depth info on a number of Models: http://www.georgesbasement.com

Things to check:

This section provides an overview of across the board issues and ailments the plague second hand hand drills.

Firstly

Always give the handle a turn, you can tell a lot from how smooth it goes round; obviously take into account rust and dirt... these can usually be easily removed.

Chuck springs

It is quite common for the springs in the chuck to be bent or otherwise damaged, even outright missing. Check this by seeing if all the jaws line and open up as they should, it is quite obvious when something is wrong (look at example below).

A chuck with bad springs

Very damaged/Missing Springs by Rhyolith, on Flickr

Very damaged/Missing Springs by Rhyolith, on FlickrA chuck with good springs

Un-damaged Springs by Rhyolith, on Flickr

Un-damaged Springs by Rhyolith, on FlickrThe best way around this is to buy drills with springless or protected spring chucks, these very rarely require more than a clean to get working well.

Protected Spring Chuck by Rhyolith, on Flickr

Protected Spring Chuck by Rhyolith, on FlickrSide Handle

Whether or not a missing side handle is an issue depends very much on the model of drill and what your going to use it for. Functionally a breast drill (or a drill your going to use as a breast drill) should have a side handle, this basically means most large hand drills (minus pillar/bench drills). For smaller drills it matters far less and many of the smallest models never had one to start with.

For collectors the drills are worth a lot more with there original side handles, so if you want your investment to hold its value (only really an issue with expensive models) then this is worth thinking about.

An example of a drill with a side handle. In nearly all cases they are attached via a machine thread in order for easy removal (for transport/to fit into difficult spaces).

Millers Falls No.120B by Rhyolith, on Flickr

Millers Falls No.120B by Rhyolith, on FlickrGear Teeth

Worn teeth are hard to spot if you don't know what un-worn teeth look like, so here is an example of worn and un-worn teeth on two drills of the same model.

Worn Cogs by Rhyolith, on Flickr

Worn Cogs by Rhyolith, on Flickr Un-worn Cogs by Rhyolith, on Flickr

Un-worn Cogs by Rhyolith, on FlickrWorn teeth are also a pretty good sign that the drill has been either used a lot or abused in its past, so worth steering clear of.

Missing gear teeth are generally easier to spot, just give the handle a couple of turns and check all the gears carefully. Completely missing teeth (such as below) are a problem, however partially missing or chipped teeth (such as below also) are not so long as there are not too many of them (too many probably means there is an issue with the metal on the gears). North Brothers "Yankee" Drills are particular prone to losing teeth on all their gears, but its worth checking on all makes and models.

Completely missing

Missing Cog/tooth by Rhyolith, on Flickr

Missing Cog/tooth by Rhyolith, on FlickrPartially missing/chipped

Partially Missing cog/tooth by Rhyolith, on Flickr

Partially Missing cog/tooth by Rhyolith, on FlickrPlay Main Gear

This is a more subtle issue that is not always apparent from a simple turn of the handle, so its worth testing for specifically. It commonly effects most models of hand drills in the main drive gear (one with the crank). This play can make an otherwise flawless drill run horribly roughly or jam when put under load (drilling). How I check is shown in the videos below (click on images to play videos):

A drill with too much play:

Yankee No.1545 with too much play by Rhyolith, on Flickr

Yankee No.1545 with too much play by Rhyolith, on FlickrA drill with an acceptable amount of play:

Yankee No.1555 with acceptable play by Rhyolith, on Flickr

Yankee No.1555 with acceptable play by Rhyolith, on FlickrA a drill as close to perfect as you can expect to find:

Millers Falls no.97 with nearly no play by Rhyolith, on Flickr

Millers Falls no.97 with nearly no play by Rhyolith, on FlickrDesign Features

This section gives an overview of the more different designs and mechanisms in order to help you choose drills suitable for your needs

Chucks

Chucks are important, they often determine what a drill can be used for. The most common varianty in hand drills is the "Standard Spring" in which the jaws fitted together with 3 coiled springs in a triangular shape, these are very prone to getting damaged and there are alternatives:

First is McCoy's springless, found on several smaller Millers Falls Models such as the example from a Millers Falls No.3 below. These chucks have and addictively smooth motion and are moderately common on Millers Falls Nos.1,3 & 5 (sometimes on No.2s, but rare). Their main weakness is that the jaws do not pull back automatically when the chuck is loosened so you either have to push them in yourself or turn the drill upward and let gravity do it, its not a major problem but does add to the faff factor. So these are great if your not bothered about working quickly.

McCoy's Springless Chuck (Millers Falls No.3) by Rhyolith, on Flickr

McCoy's Springless Chuck (Millers Falls No.3) by Rhyolith, on FlickrThe Jacobs provides an unparalleled firm grip at the cost of having a chuck key to faff about with (and loose). These are good on drills that never leave the workshop, as then the issue of the chuck key is that much less annoying. Also the chucks firm grip makes it ideal for large drills, though few large hand powered drills have Jacobs.

The Modern Keyless Chuck is possibly the best all round, but only the footprint drills seem to have it (such as the example below). Most will be familiar with these as they are pretty much the norm for modern cordless electric drills.

Modern Keyless Chuck (Footprint Hand Drill) by Rhyolith, on Flickr

Modern Keyless Chuck (Footprint Hand Drill) by Rhyolith, on FlickrProtected Spring Chuck is essential a standard spring chuck without the same reliability issues (illustration in the "chuck springs section). They are pretty standard on many higher grade models, with many models from Stanley, North Bros, Millers Falls, Record and SIF having them. Two common variants for small drills listed here:

Stanley small hand drill variant (more or less identical to Record, SIF, some Millers Falls and North Brothers variants)

Protected Spring Chuck (Stanley No.803) by Rhyolith, on Flickr

Protected Spring Chuck (Stanley No.803) by Rhyolith, on FlickrThe North Brothers "Yankee" Variant, this is used on more or less all North Bros Drills (only the size varies).

Protected Spring Chuck (Yankee No.1430) by Rhyolith, on Flickr

Protected Spring Chuck (Yankee No.1430) by Rhyolith, on FlickrHow many pinions?

Most hand drills will have Between one and two pinions, with some more sophisticated models have 3 or 4. Generally 2 pinions are better as the idler pinion supports the main crank gear keeping it in engagement which his a particular advantage under heavier loads, this also applies to most with more than 2.

Single Pinion Hand Drill

Stanley No.805 by Rhyolith, on Flickr

Stanley No.805 by Rhyolith, on FlickrTwo Pinion Hand Drill

Millers Falls No.2 (2 Pinion Model) by Rhyolith, on Flickr

Millers Falls No.2 (2 Pinion Model) by Rhyolith, on FlickrThree Pinion Hand Drill

North Brothers "Yankee" No.1445 by Rhyolith, on Flickr

North Brothers "Yankee" No.1445 by Rhyolith, on FlickrFour Pinion Hand Drill

Millers Falls No.97 by Rhyolith, on Flickr

Millers Falls No.97 by Rhyolith, on FlickrGenerally speaking single pinion drills are great for low load tasks (drilling small holes) due to the reduction in friction from only having one pinion. However under heavier load these one pinion designs struggle with the gears wanting to pop out of their mesh, meaning all but the smallest good hand drills will have more than 1-pinion or an Equaliser.

Equalisers

Equalisers are and alternative method of supporting the main crank gear that is generally superior to a second pinion, as it achieves the same thing with less friction and play. Equalisers also tend to support the gear more firmly than a second pinion and don't have as bad a rasping effect under heavy load, if any at all.

The Millers Falls No.2 was produced in both 2-pinion and equaliser variants over its long production life, making it an excellent example of the superiority of equalisers. Though both models of the No.2 are un-doubtable excellent, the equaliser model is just that bit smoother, particularly under heavy load. See the mechanisms of both here:

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr 2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr 2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on Flickr

2-Pinion & Equaliser Millers Falls No.2 by Rhyolith, on FlickrOther Equaliser variants are generally not as effective as the No.2's roller, but still better than a second pinion:

Goodall Pratt No.5 1/2 Equaliser by Rhyolith, on Flickr

Goodall Pratt No.5 1/2 Equaliser by Rhyolith, on Flickr Equaliser Pin Millers Falls No.200 by Rhyolith, on Flickr

Equaliser Pin Millers Falls No.200 by Rhyolith, on FlickrEqualisers are more or less unique to higher quality drills, so if you holding a model with an equaliser than its probably a good drill.

Ratchets, Bells and Whistles

There are a number of models out there with more sophisticated mechanisms to control the torque and allow drilling in difficult places.

The most common are in-bulit ways of changing gear that means a lower or higher gear can be engaged without having the remove the drill from the work. Often found on premium breast drills these mechanisms are highly desirable and a sign that the drill was a premium model in its day (so good quality).

This Yankee No.1445 has a switch on the main frame that allows the gears to be changed.

North Brothers "Yankee" No.1445 by Rhyolith, on Flickr

North Brothers "Yankee" No.1445 by Rhyolith, on FlickrRatchets are rarer and perhaps less useful, made for the more specialised task of allowing drilling in tight spaces.

Millers Falls No.200 has a basic ratchet similar to a ratcheting wrench

Ratchet mechanism Millers Falls No.200 by Rhyolith, on Flickr

Ratchet mechanism Millers Falls No.200 by Rhyolith, on FlickrDouble Ratchets essentially for fill the same purpose as standard ratchets, but are more efficient as the drive is in both directions (forward and backward cranks), these mechanisms are only found on a handful of models and are highly sought after... mainly because they are awesome!

This North Bros No.1530 can use its selection of ratchets and tiny size to work in very tight spaces.

North Brothers "Yankee" No.1530 by Rhyolith, on Flickr

North Brothers "Yankee" No.1530 by Rhyolith, on FlickrOf course with a select few models the companies decided to go all out then you get the North Bros "Yankee" No.1555 and Millers Falls No.97

North Brothers "Yankee" No.1555 by Rhyolith, on Flickr

North Brothers "Yankee" No.1555 by Rhyolith, on Flickr Millers Falls No.97 by Rhyolith, on Flickr

Millers Falls No.97 by Rhyolith, on FlickrGenerally the models with ratchets and gear changes are sort after and expensive. Functionally the 2-gear mechanisms are more useful, particularly on large drills. The ratchets come into there own in fairly specific situations (tight, but no too tight spaces) and are more useful to most modern users on a small drills for cabinet making etc.

Adjustable Handles

There are a small number of models with specialised or adjustable handles. As these are fairly individually unique, so I will just put pictures here. They are generally geared towards fitting into tight spaces or personal preference of how to hold a drill.

Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr

Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr

Suffolk Iron Foundry (SIF) Air Ministry (A.M) Hand Drill 1942 by Rhyolith, on Flickr Record No.125 "Improved" by Rhyolith, on Flickr

Record No.125 "Improved" by Rhyolith, on Flickr Record No.125 "Improved" by Rhyolith, on Flickr

Record No.125 "Improved" by Rhyolith, on Flickr Footprint Hand/Breast Drill by Rhyolith, on Flickr

Footprint Hand/Breast Drill by Rhyolith, on Flickr Leytool Drill by Rhyolith, on Flickr

Leytool Drill by Rhyolith, on Flickr Proto Hand Drill by Rhyolith, on Flickr

Proto Hand Drill by Rhyolith, on FlickrMakes & Models

You can spend a long time looking up the best makes and models, which is worth it if you really want "the best" however for the sake of a short guide here is a list of makes that are more or less universally good quality.

- Millers Falls

- North Brothers "Yankee" (Look out for damaged teeth)

- Goodell Pratt (linked to Millers Falls

- Record

- SIF (Suffolk Iron Foundry)

- Leytool

- Metabo

I did not include Stanley because although they made some very good drills, they also made some of the worst ones I know of (mostly the newer models), so it being a Stanley is no guarantee of quality.

Here is a list of my Entire collection: https://www.flickr.com/photos/123749911 ... 6820616314, I try to review every single one and am adding more drills and info all the time. Its a good place to start if you want more info on makes and models and how they perform (there is plenty of info on the net too, especially for the big 3 American companies (North Bros, Millers Falls, Goodell pratt).

Makes and Models Links:

Millers Falls & Goodell Pratt: http://oldtoolheaven.com

Goodall Pratt 1926 Catalog: http://www.blackburntools.com/articles/ ... -no-16.pdf

North Brothers 1931 Catalog: http://www.blackburntools.com/articles/ ... yankee.pdf

Record Drills (scroll down): http://www.recordhandplanes.com/rare.html

I depth info on a number of Models: http://www.georgesbasement.com