CHJ

Established Member

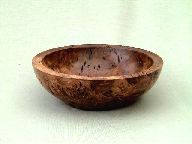

Paul.J":1cvcfc1j said:....You should have turned one thin to see how that would go.:

On the 'to do' list Paul with another offcut.

Paul.J":1cvcfc1j said:....Did those cracks disapear :?: .....

The 'cracks' if that is what they are (radial white lines) are still there and appear to be running the length of the logs (3ft's the longest)