woodbloke":2g2764zi said:Make up four honing registration blocks (like small bench hooks), two at 25deg and two at 30deg and make each pair identical. Use the 25deg blocks with a very coarse DMT and a VMkII honing guide for prepartion of the primary and do the same with the 30reg block, another VMKII and an Extra Fine DMT (the green one) so now you have two honing stations, one for the primary bevel and one for the honed bevel. Total expenditure is then four DMT's and four VMKII's, giving two sharpening guides per station...............................

Thanks Rob. We already use two honing stations but stick to one grind/honing angle.

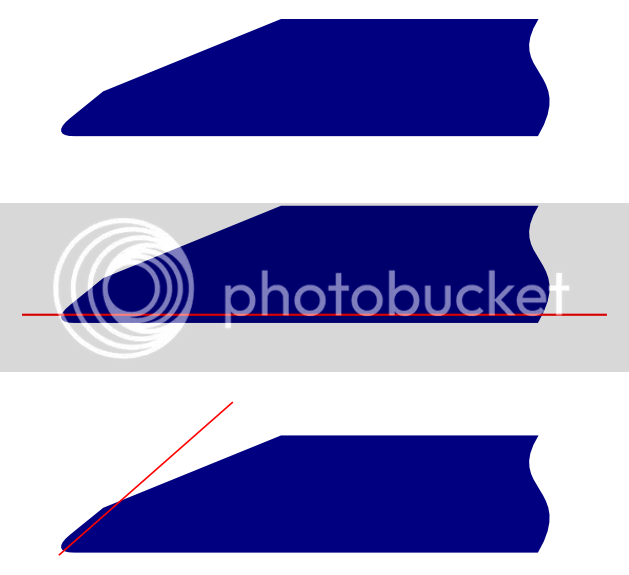

What I found was that students would steepen the angle to 30 degrees to just grind the edge, then another student the following day perhaps would find that they had to spend 'ages' honing to get a new and fresh edge. What tended to happen was that they would simply increase the angle further and thereby get a new edge, however at steadily steepening angles, which I then had to grind back.

The idea was that we would continue to teach the idea that a lot of woodworkers use primary and secondary angles when sharpening but only in theory lessons. In practical we would just use one angle, explaining why this was done. It had vastly improved the general state of the chisels found in the rack but as always, more could be done.

I am liking the look of the Veritas MkII and think it would work very well. However, with it being in two parts, that must be fitted together to certain marks I can see it being almost TOO adjustable and that there may be too much scope still for getting it wrong still.

Adjustments for steep angles, short blades, back bevels, eccentric roller adjustment.......I can just imagine a few getting a bit confused and sadly not asking what to do but diving in regardless and sharpening incorrectly.

The Dakota on the other hand looks a lot more simple, I think a road test is in order!