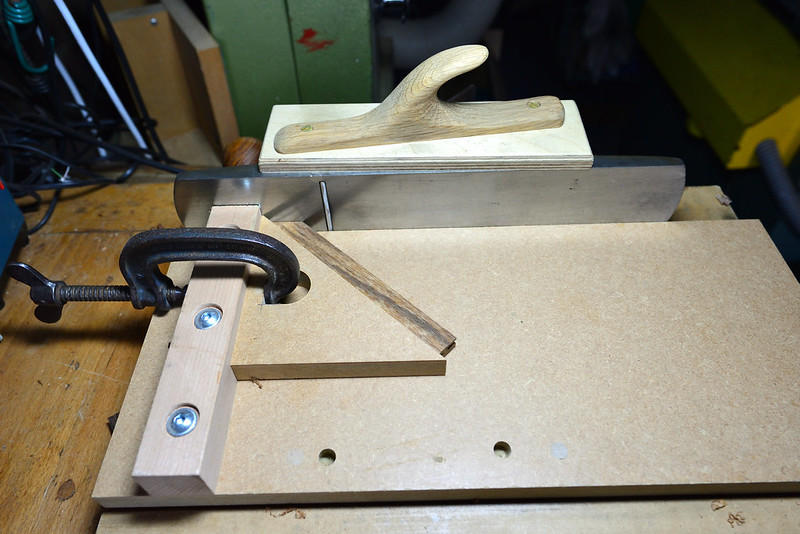

I'm squaring wood with a bandsaw and plane, so made a simple shooting board for end grain and find it ok for shorter planing with the grain. I intend to make a longer one for longer lengths with the grain. The thing is, holding the plane is hurting my hand after a while. I've used candle wax on the side and base of the plane and keeping the blade sharp but after a while it still hurts.

The only new shooting planes I can see online are £200+, and used Record T5 online for maybe a bit under £100 and I don't know the condition till I get it sent. Does anyone currently sell a cheaper shooting plane (I've searched and can't find one), or can you adapt an ordinary plane without permanently altering the base?

Thanks

The only new shooting planes I can see online are £200+, and used Record T5 online for maybe a bit under £100 and I don't know the condition till I get it sent. Does anyone currently sell a cheaper shooting plane (I've searched and can't find one), or can you adapt an ordinary plane without permanently altering the base?

Thanks