kenneth.hilton

Still learning

Hi

Im knew to this forum.

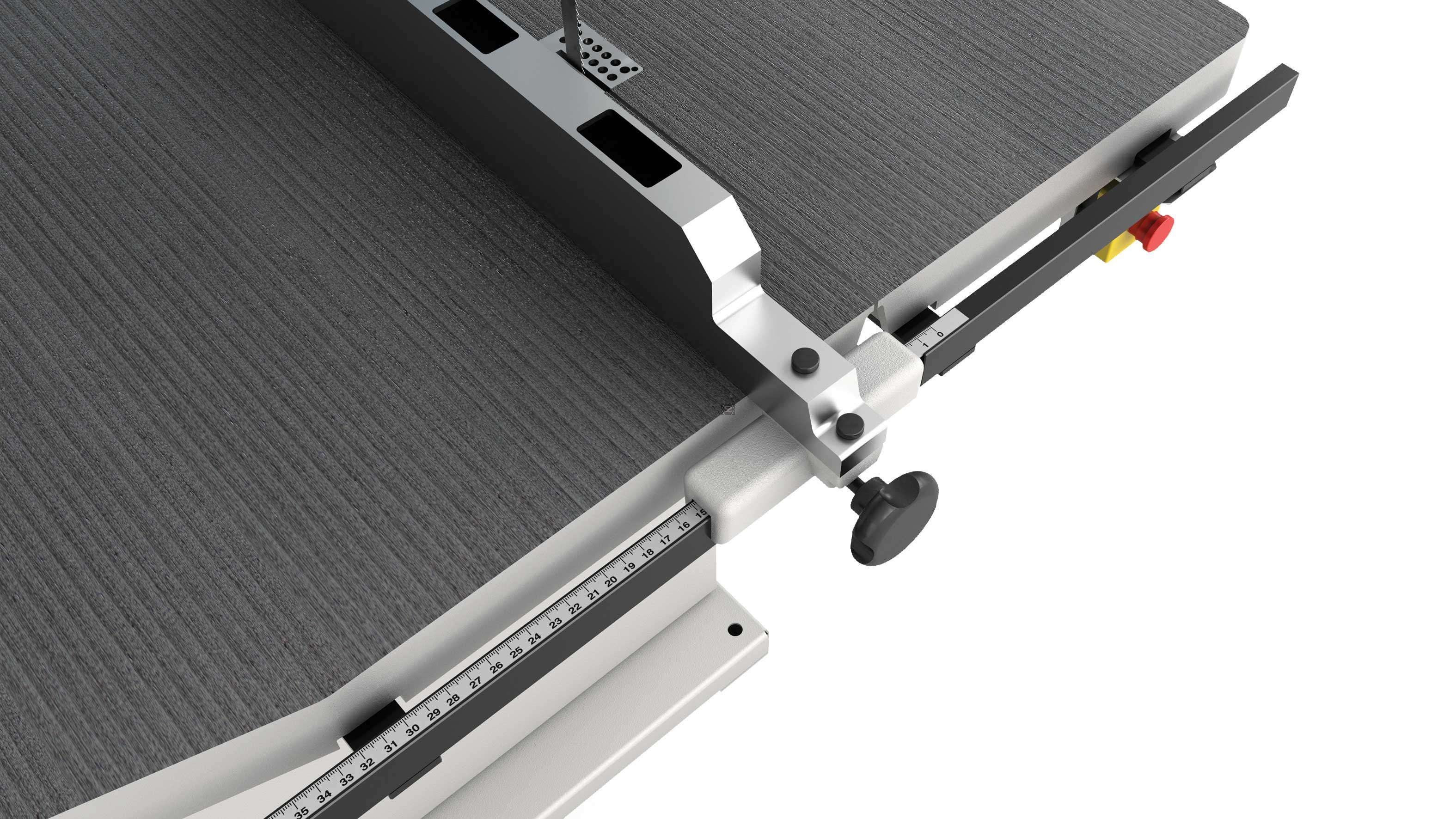

I do have a question. The workshop I am in has taken delivery of a brand new bandsaw.

When you rub your hand over the table it feels smooth in one direction and rough in the opposite ( the direction you would feed the wood)

I am of the opinion that the manufacturer sent it out like this so it is correct but my work mates think this is wrong and are keen to make the table smooth.

Can anyone advise who is correct Thanks

Im knew to this forum.

I do have a question. The workshop I am in has taken delivery of a brand new bandsaw.

When you rub your hand over the table it feels smooth in one direction and rough in the opposite ( the direction you would feed the wood)

I am of the opinion that the manufacturer sent it out like this so it is correct but my work mates think this is wrong and are keen to make the table smooth.

Can anyone advise who is correct Thanks