This is it fitted in and clamped in place. It is stuck to the rectangular inlet at the top and bottom with a small bead of gripfill.

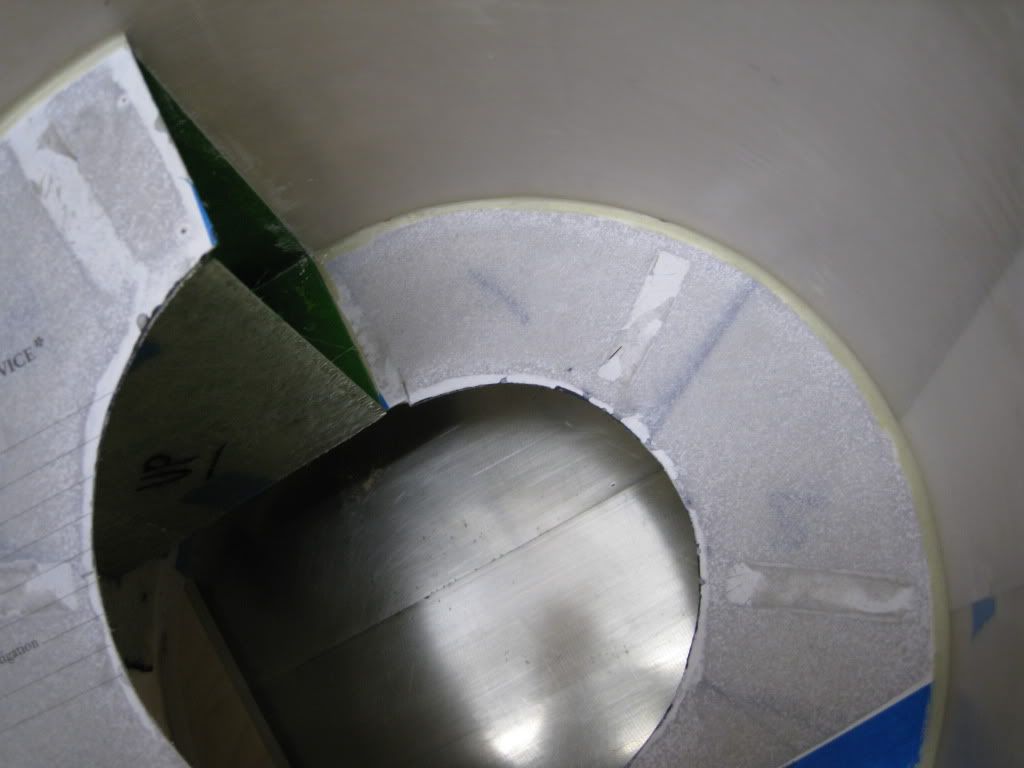

Viewed from above

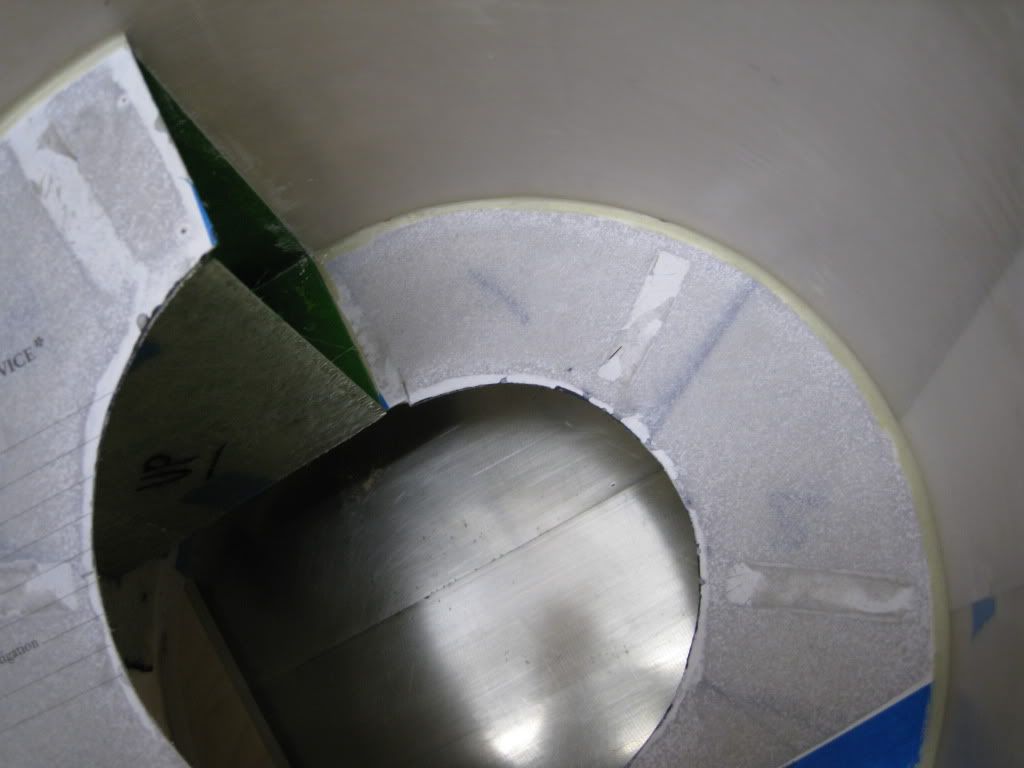

And the buisness end below. The ramp is joined to the drum with a bead of gripfill above and below all round the edge

I'm now very pleased with it. Its a good fit and very smooth. I now need to build up the layers of resin on the buisness side (bottom) and resin and mat above and extend the matting up the sides of the drum.

Thats all for now

Mark

Viewed from above

And the buisness end below. The ramp is joined to the drum with a bead of gripfill above and below all round the edge

I'm now very pleased with it. Its a good fit and very smooth. I now need to build up the layers of resin on the buisness side (bottom) and resin and mat above and extend the matting up the sides of the drum.

Thats all for now

Mark