Al

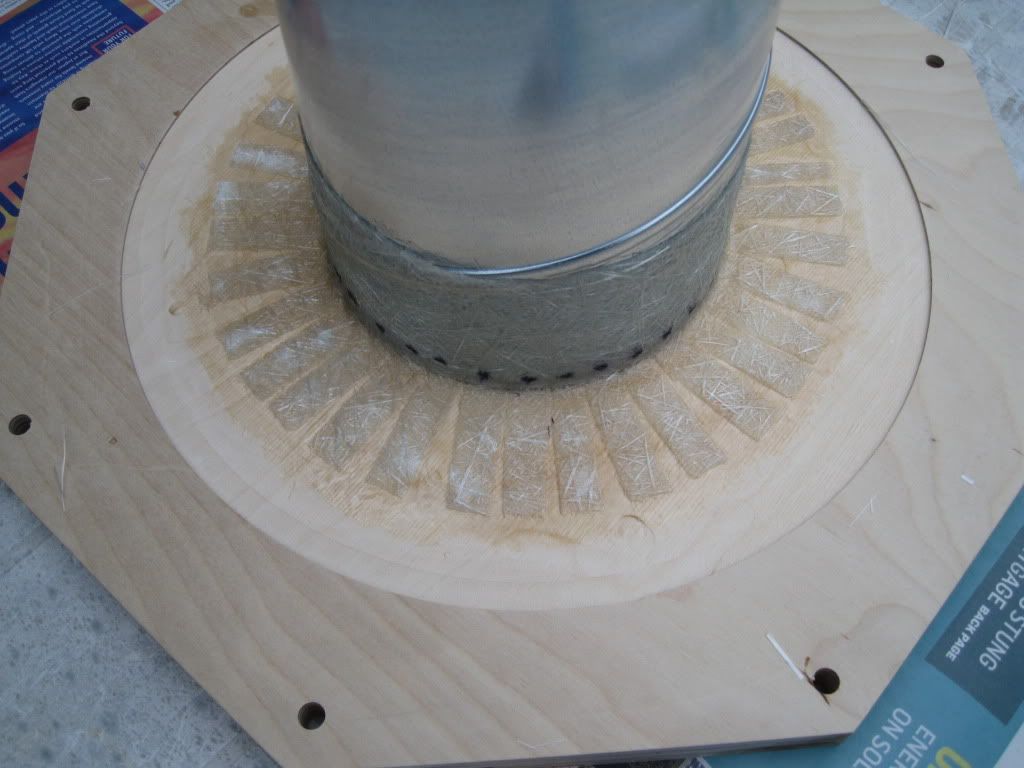

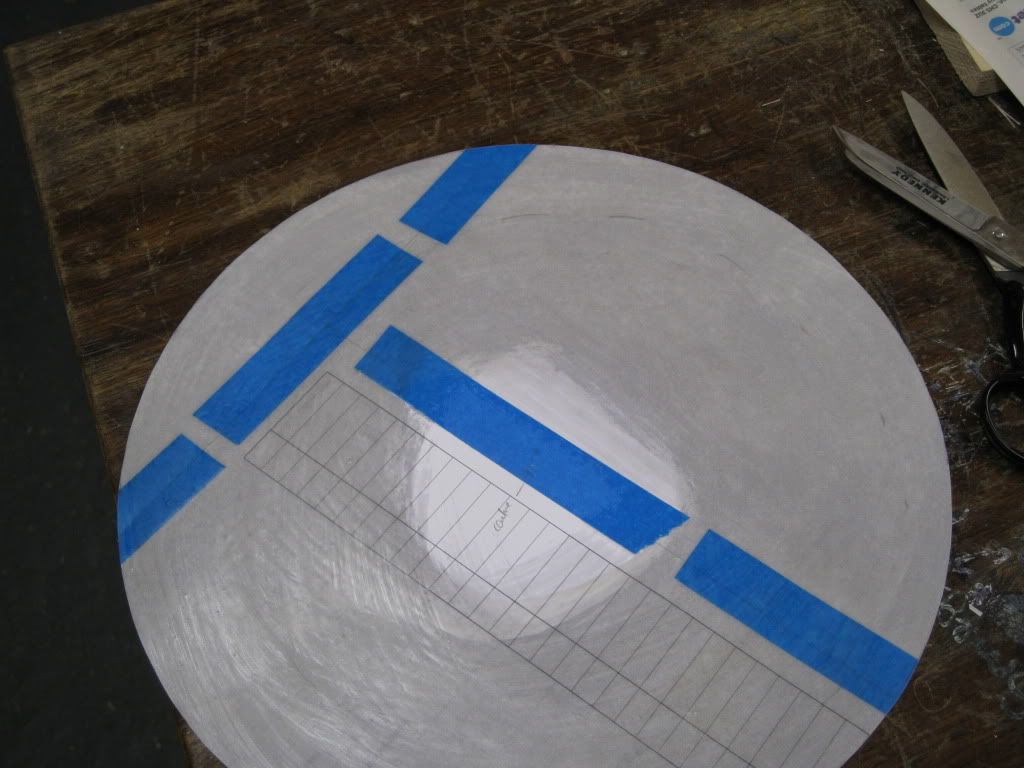

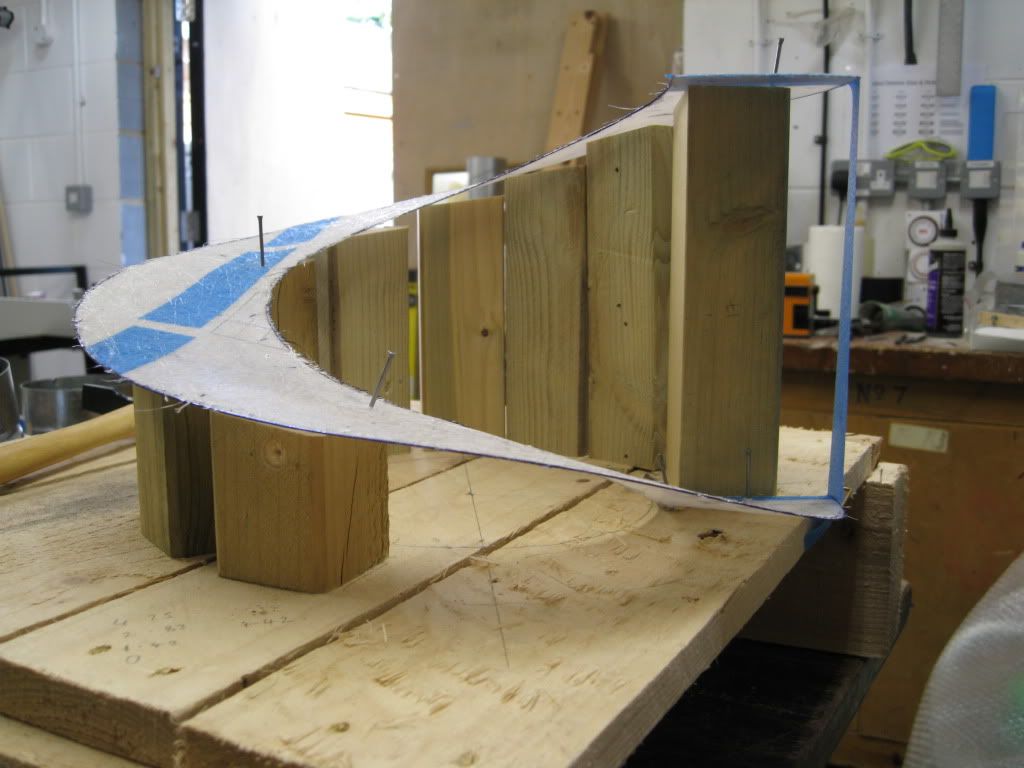

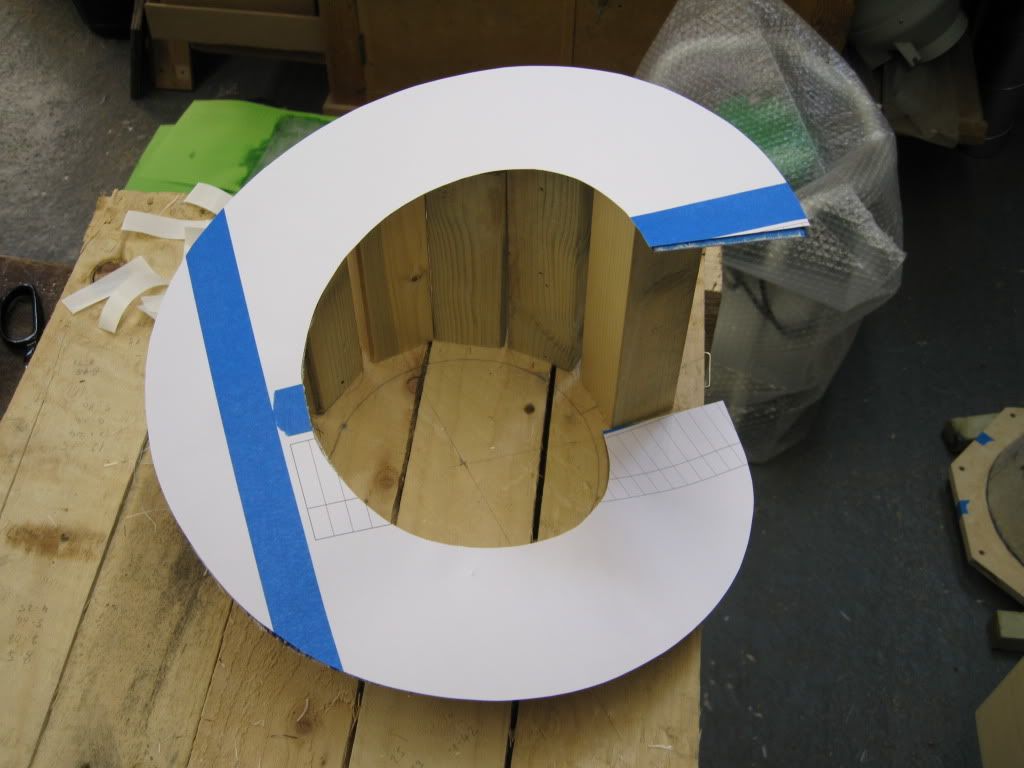

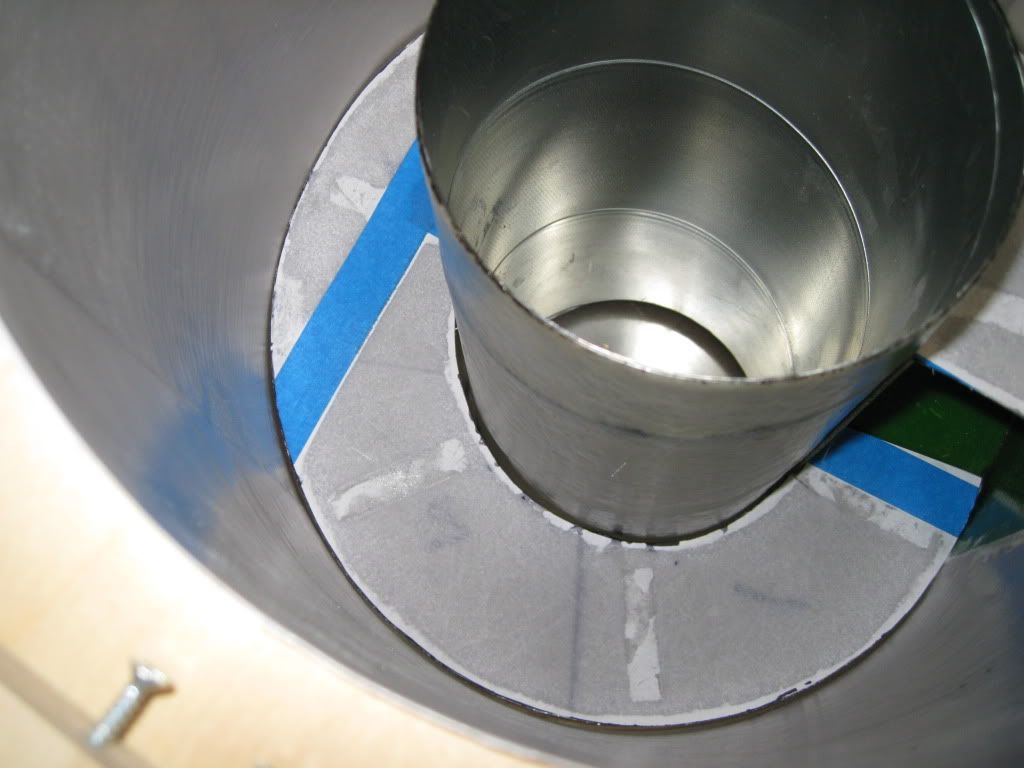

As I understand it the only place that suffers from constant bombardment and consequential wear is the area opposite the incoming ducting (well this is according to Mr Pentz and we shall not argue with God). To that end if the final design allows access to this area then another coat of resin would be easily applied, or if you wished a small section of Kevlar Cloth could be laminated into this area for the ultimate bomb proof solution.

My experience (boatbulding) with fibreglass and resin, although I prefer epoxy to polyester, is that it's extremely strong and offers good wear resisitance. Plus it is really easy to repair, replace, modify, create molded parts etc and generally fabricate into things that you couldn't make as easily by any other method. Only down side is it can if you are not careful it will become a sticky and therefore messy process.

So far I'm loving the build.

Regards

Richard