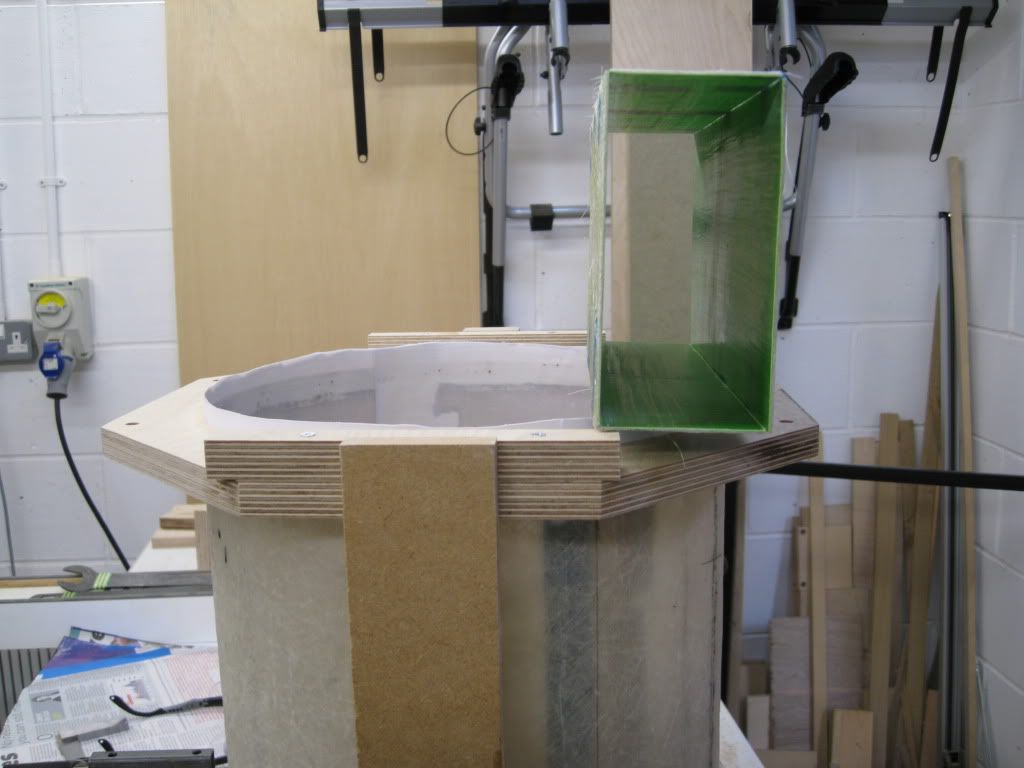

I then started to build the air intake. Ideally I needed some thin flat plastic. But I didn't have any so I used some more cardboard

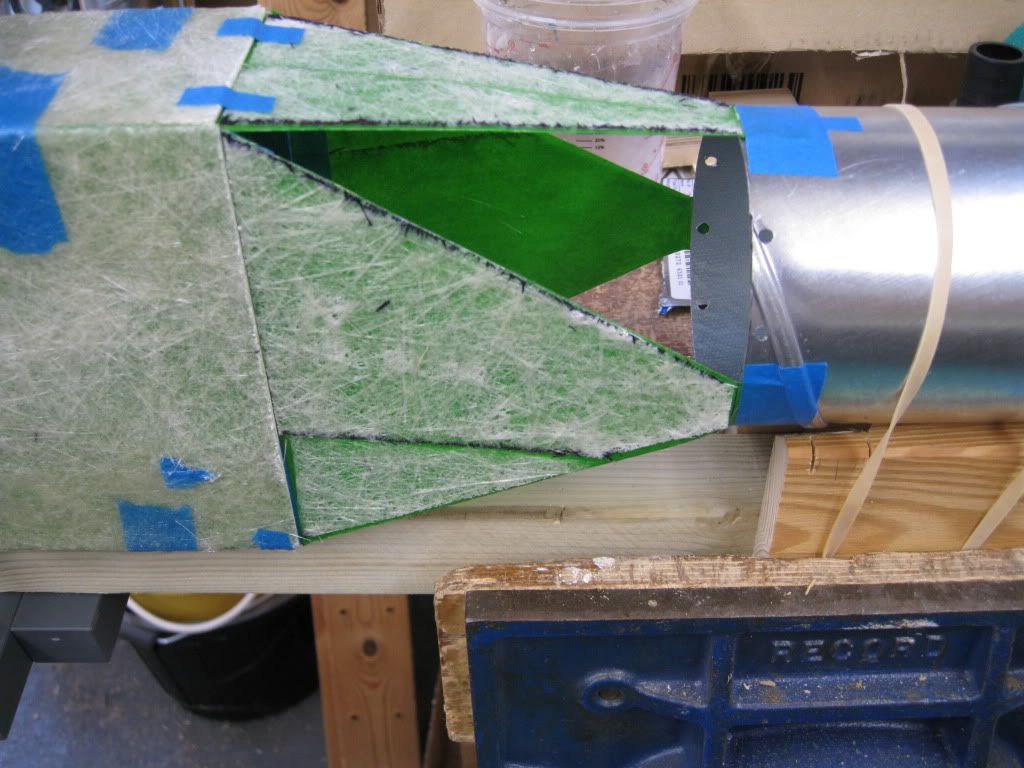

I the built up several layers of resin and matting on it

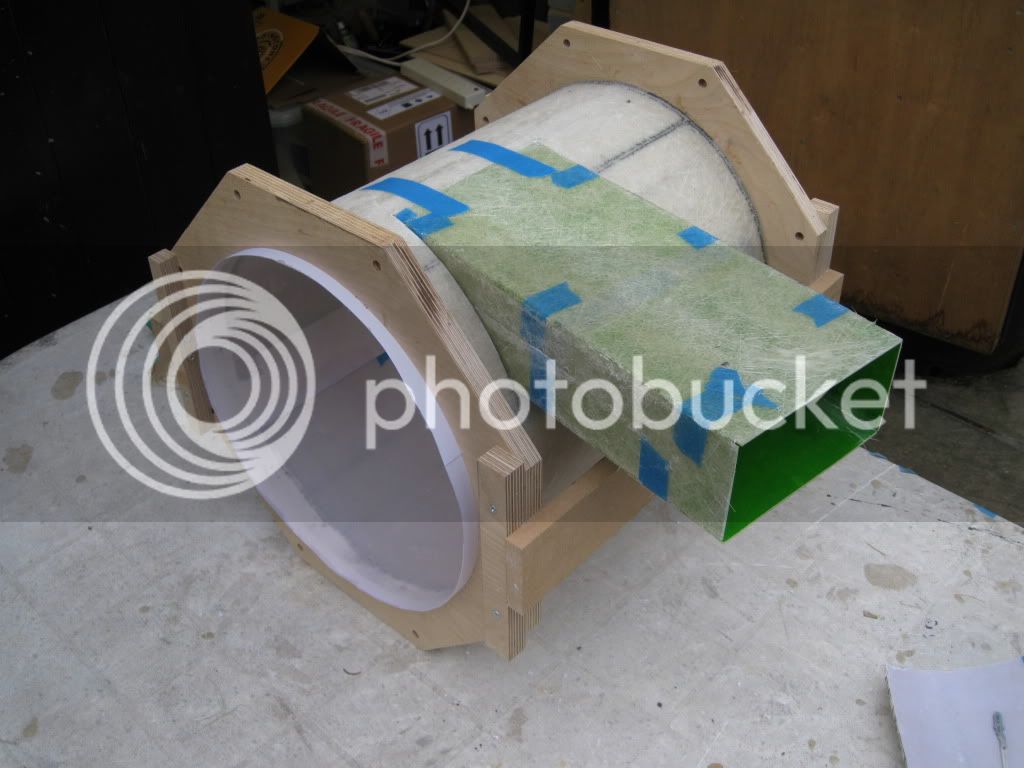

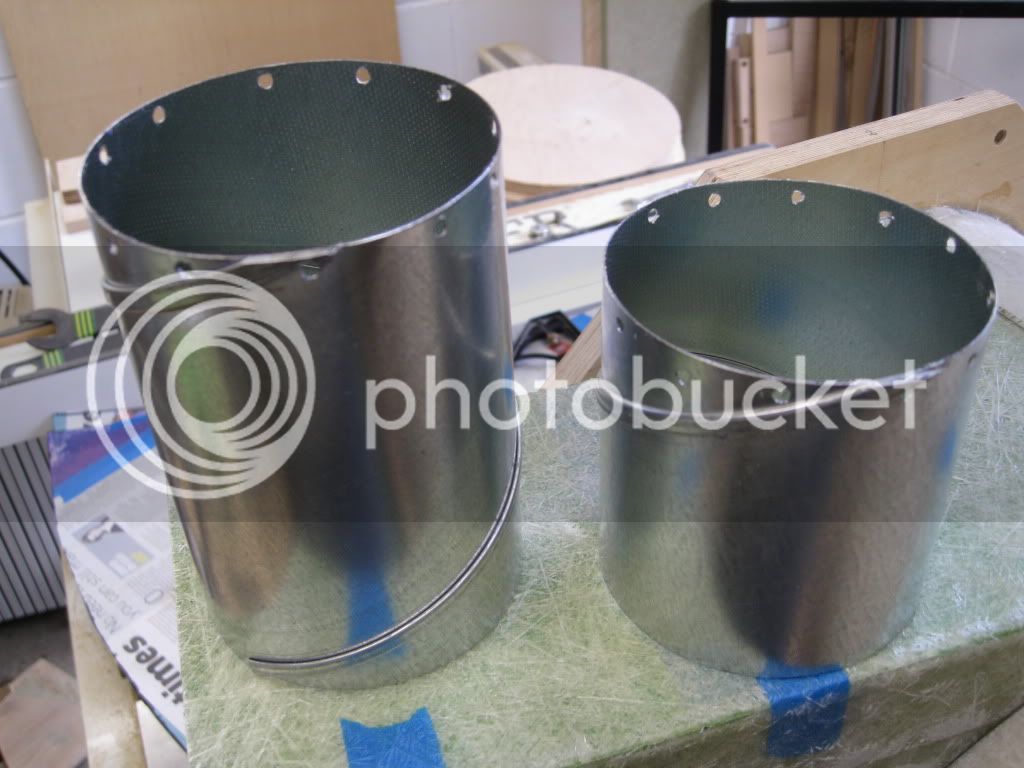

When done I hacksawed it down to the sizes I needed

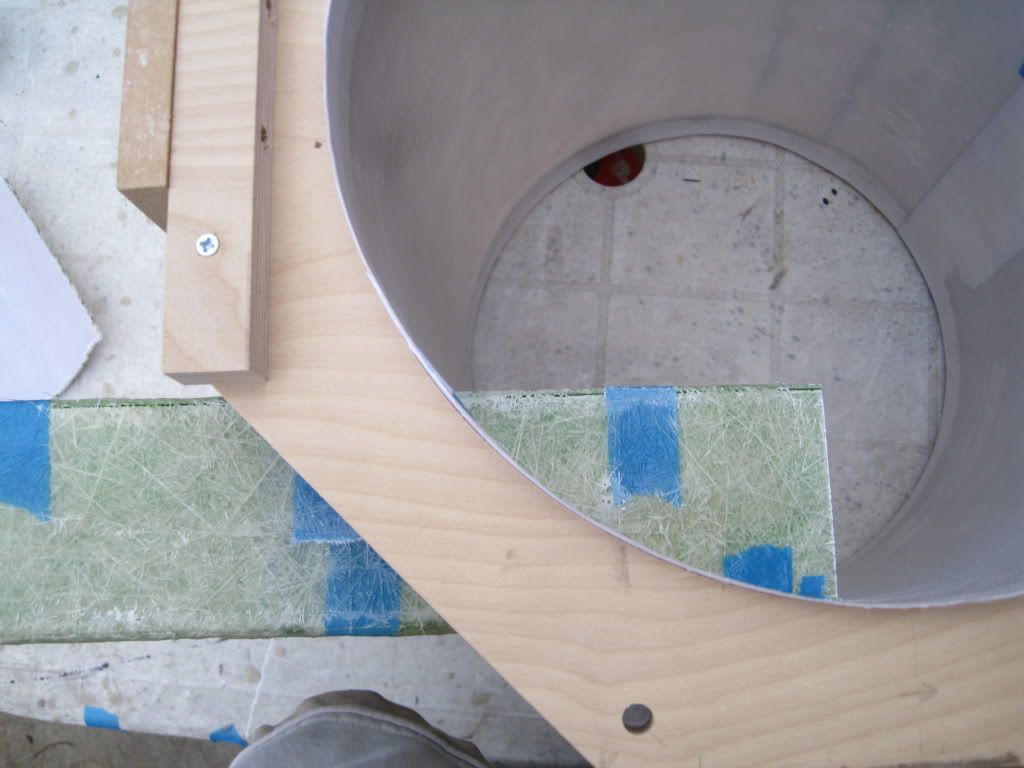

Then stuck it together with masking tape and set it with resin and matting

Mark

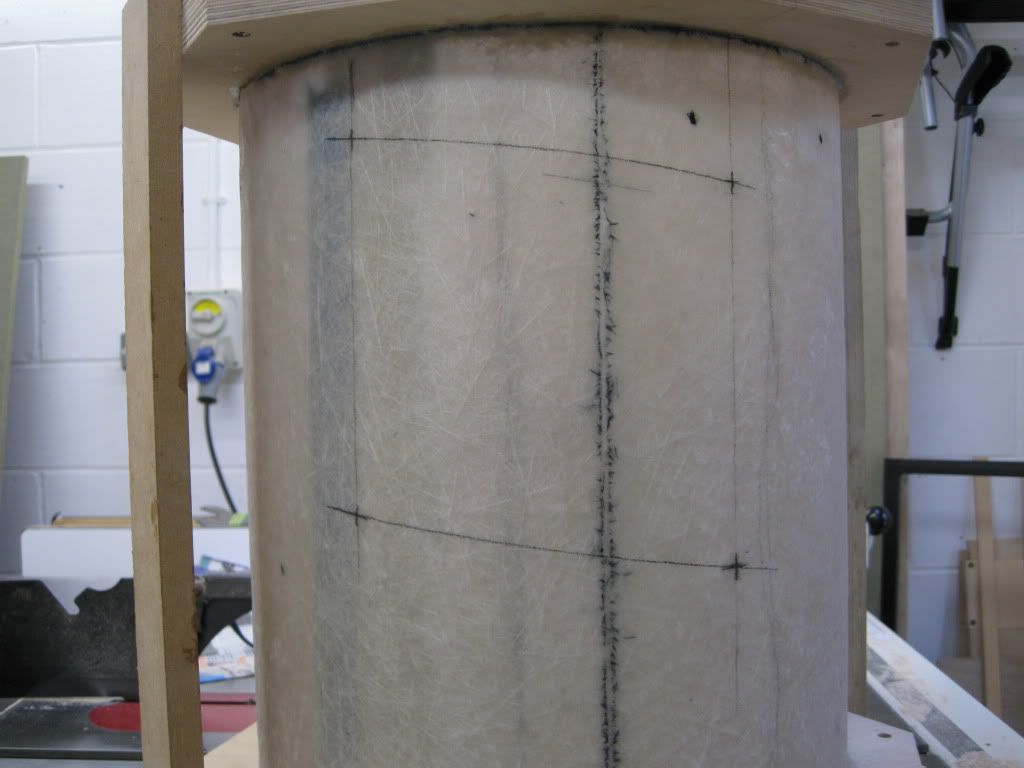

I the built up several layers of resin and matting on it

When done I hacksawed it down to the sizes I needed

Then stuck it together with masking tape and set it with resin and matting

Mark