Thanks guys. Really glad you are enjoying the thread.

Last update before Christmas, hope you all have a good one. Eat, drink and be merry!

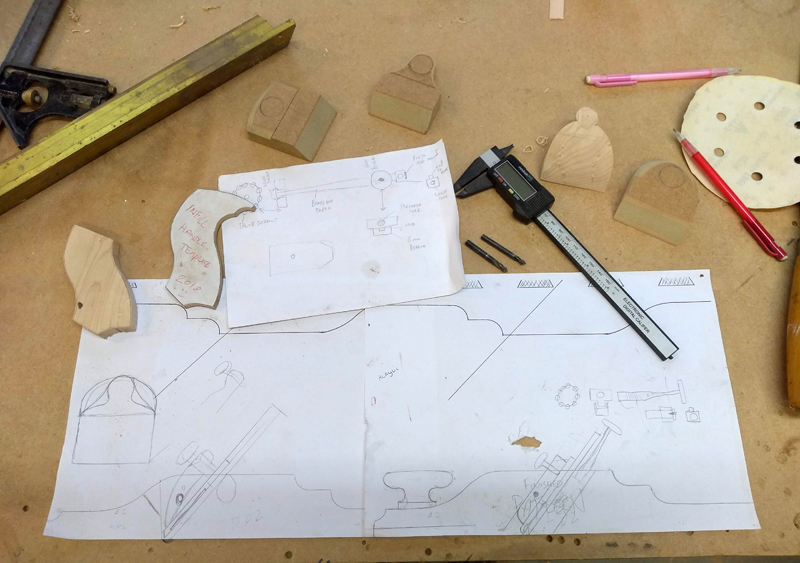

Next I returned to the blade.

From the beginning of the project I wanted to add a makers mark to the plane which is normally placed onto the blade.

I researched as many methods of doing this as I could and after weighing up the pros and cons decided Electro etching might work out the best.

Again this is something completely new to me and I was uncertain if it was even going to work how I wanted it to, or if I could even achieve it.

I started by designing a mark in Photoshop. My initials and my daughters name.

I'm fortunate to have a friend with his own laser cutter. Its not powerful enough to etch steel but can cut a perfect stencil.

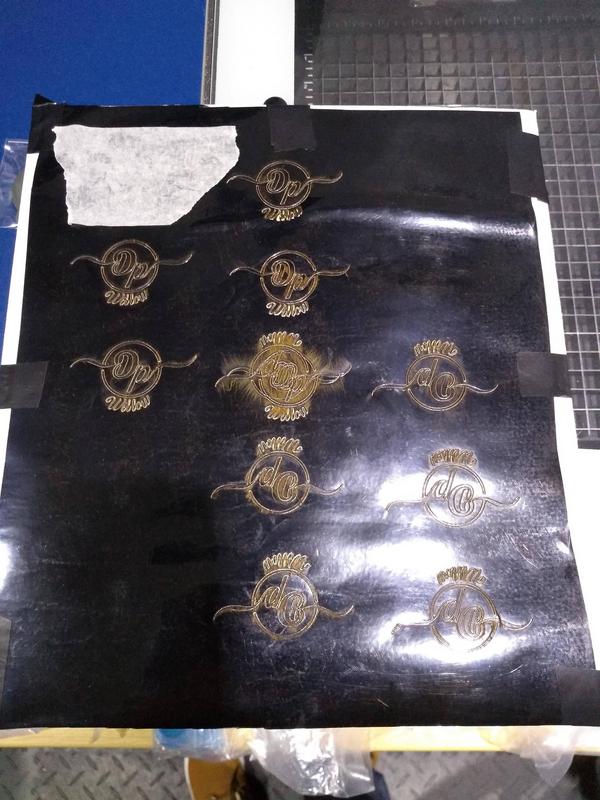

I'm using black vinyl wrap for the stencil and after a few tries and creating a small fire inside his machine we get the settings dialled in for a perfect cut. (He wasn't happy about the fire!)

Unsure of how many attempts it would take me I asked him to cut a few to practise with.

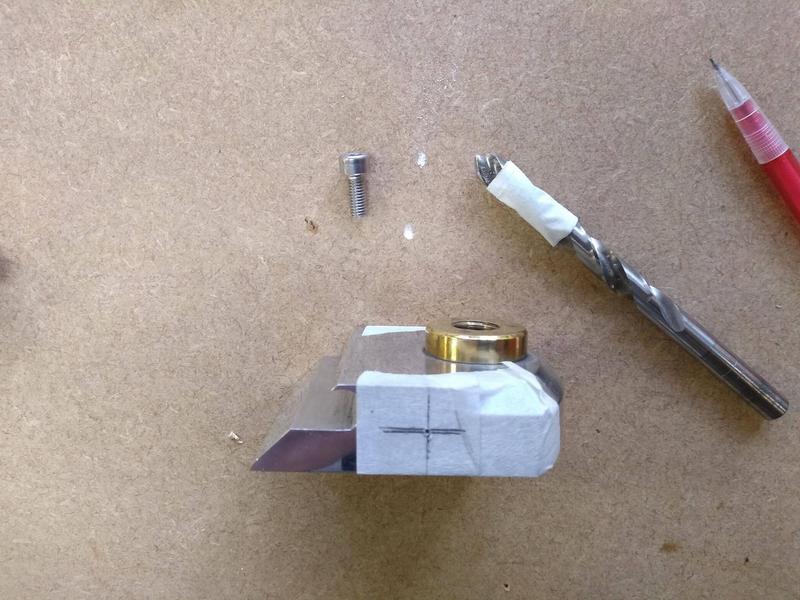

I cut one of the stencils out and stuck it to an off cut of steel.

Using an old 12 volt battery charger I connect the positive wire to the steel and the negative to a cotton bud that had been dipped in a salt water solution, 1 part salt to 4 parts water.

I then moved the cotton bud around the stencil holding it in place for 5-10 seconds before moving on to a new part. Changing the cotton bud regularly as it starts to blacken and burn.

after 15 minutes or so I removed the stencil.

I ran my finger over the mark and disappointingly it had not etched at all but only left a burn mark through the stencil that was now rubbing away with my finger.

I'd done something wrong and my first guess was connecting the positive and negative incorrectly.

So after changing them over and another 15 minutes later I removed the stencil and to my surprise it had worked and, worked far better than I was anticipating!

Happy with the results It was time to try it on the real thing.

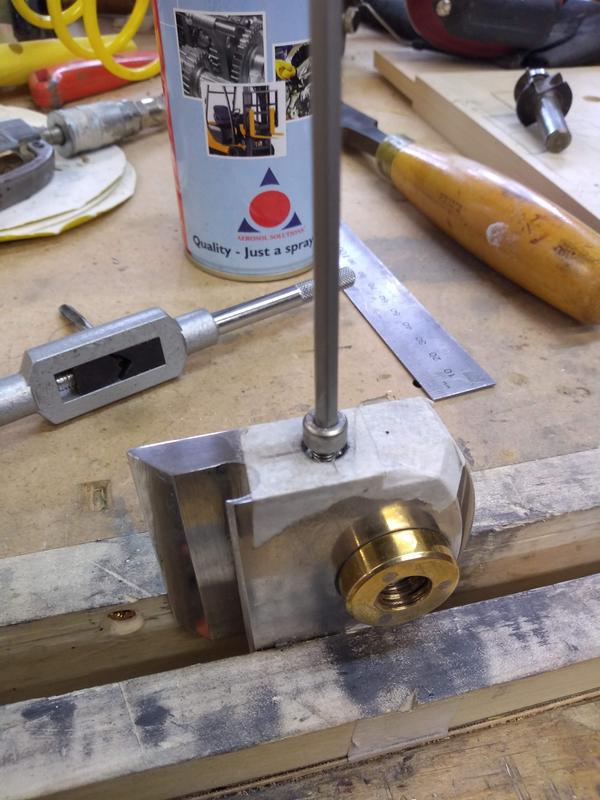

Good placement of the stencil was important. After a few attempts I got it where I wanted it.

I stuck the stencil to some masking tape and carefully removed the backing.

The masking tape helps to place the stencil and once stuck down is removed. I then masked out around the stencil to prevent any salt water etching where I didn't want it to.

I spent more time etching the blade as I knew the steel was harder than my test piece and I wanted a deep etch. It took around 35-40 minutes

Removing the stencil the etch is looking good so far, there is a little water bleed through in parts.

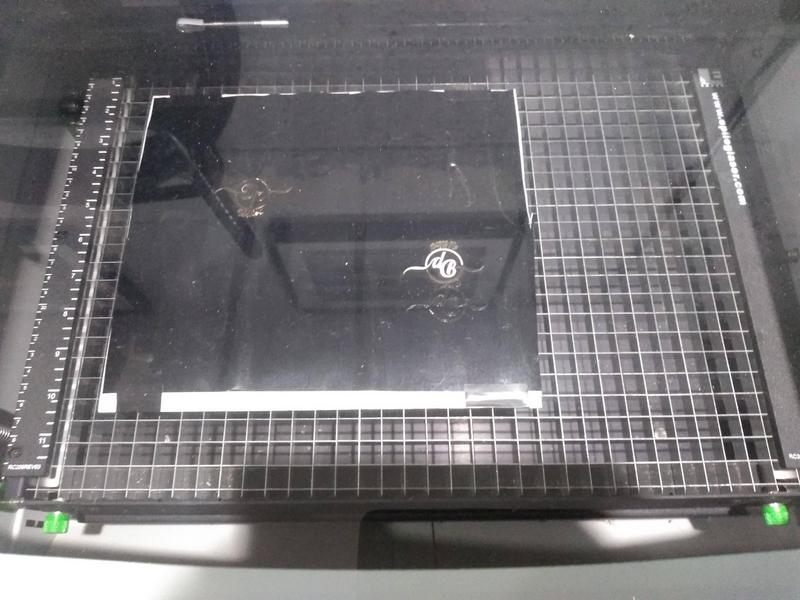

With the stencil removed you can see the etch is darkened by the burnt salt water and cotton bud.

I used fine wet and dry paper to clean it up and remove the water marks.

I then used a tooth brush and some Autosol to clean the burn marks out of the etch. Once I was happy I gave the blade a quick polish too.

I'm absolutely delighted with the results, I never expected it to come out so well.

While I'm sure the mark isn't to every ones taste it means something to me and I'm really happy with it.

It's also another process I've learnt through the making of this plane which I'd never know about in my day to day work.

The plane really is starting to take shape now, there isn't long to go.

Merry Christmas all.