RussellT

Member

Hi All

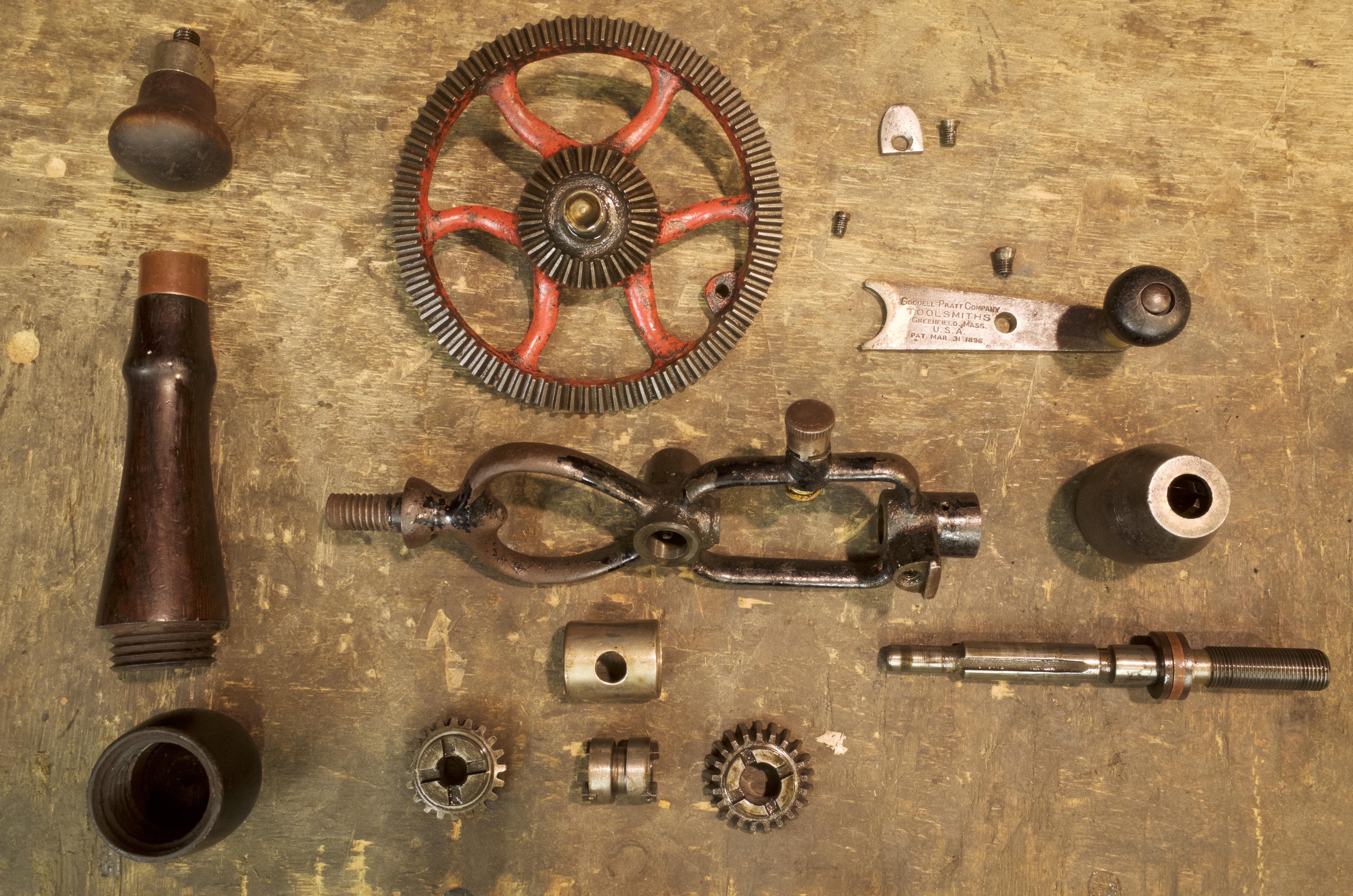

I am trying to repair a Goodell Pratt 5 1/2 B hand drill that belonged to my father and to his father.

I've made a bit of progress but I still have some questions.

My questions are: Does anyone have or know where I can get a slow speed pinion?

Could anyone provide a dimensioned sketch of the mushroom inside the chuck? The chuck is the type with three coil springs.

Can anyone date this drill for me?

The main handle on the drill had clearly been repaired before and the ferrule had been redrilled and had a "pin" retaining the handle. The pin was six strands of copper wire with nasty sharp ends.

I took the pin out and removed the handle. I discovered a piece of wood had been let into the handle and the extra hole through the ferrule had been drilled through the threaded iron of the drill. Unfortunately it had missed.

The metal between the original and the new hole had also cracked.

After some thought I decided that this had to be fixed. My objective is to make this a usable tool and this would eventually have broken. I cut the old thread off and drilled the frame with an 8mm hole. I found a bolt with the same thread as the original and turned that down to 8mm and loctited the two together.

The next problem I tackled was that the crank knob wouldn't rotate. I thought this was probably due to rust on the shaft. I drilled off the riveted over end and removed the knob. I hit a big snag here. I thought the shaft was tight in the knob because it was rusty. It turned out that the shaft was too short because of previous attempts to tighten up the riveting. That had also swollen the end of the shaft inside the knob, so the knob split as I tapped out the shaft. I glued it back together. I used superglue because the low viscosity meant I could get it in without having to remove the small brass ferrule from the knob. I turned a new shaft and re-riveted the knob in place.

The remaining jobs are:

To repair the main handle - I think that should be OK once I've worked out how to hold it in the lathe to clean up the hole so I can let in some new wood.

To make a new mushroom for inside the chuck. Can anyone help me with dimensions please?

To replace the slow speed pinion. Any suggestions will be gratefully received.

Russell

I am trying to repair a Goodell Pratt 5 1/2 B hand drill that belonged to my father and to his father.

I've made a bit of progress but I still have some questions.

My questions are: Does anyone have or know where I can get a slow speed pinion?

Could anyone provide a dimensioned sketch of the mushroom inside the chuck? The chuck is the type with three coil springs.

Can anyone date this drill for me?

The main handle on the drill had clearly been repaired before and the ferrule had been redrilled and had a "pin" retaining the handle. The pin was six strands of copper wire with nasty sharp ends.

I took the pin out and removed the handle. I discovered a piece of wood had been let into the handle and the extra hole through the ferrule had been drilled through the threaded iron of the drill. Unfortunately it had missed.

The metal between the original and the new hole had also cracked.

After some thought I decided that this had to be fixed. My objective is to make this a usable tool and this would eventually have broken. I cut the old thread off and drilled the frame with an 8mm hole. I found a bolt with the same thread as the original and turned that down to 8mm and loctited the two together.

The next problem I tackled was that the crank knob wouldn't rotate. I thought this was probably due to rust on the shaft. I drilled off the riveted over end and removed the knob. I hit a big snag here. I thought the shaft was tight in the knob because it was rusty. It turned out that the shaft was too short because of previous attempts to tighten up the riveting. That had also swollen the end of the shaft inside the knob, so the knob split as I tapped out the shaft. I glued it back together. I used superglue because the low viscosity meant I could get it in without having to remove the small brass ferrule from the knob. I turned a new shaft and re-riveted the knob in place.

The remaining jobs are:

To repair the main handle - I think that should be OK once I've worked out how to hold it in the lathe to clean up the hole so I can let in some new wood.

To make a new mushroom for inside the chuck. Can anyone help me with dimensions please?

To replace the slow speed pinion. Any suggestions will be gratefully received.

Russell