HarryCrumb

Member

Hi,

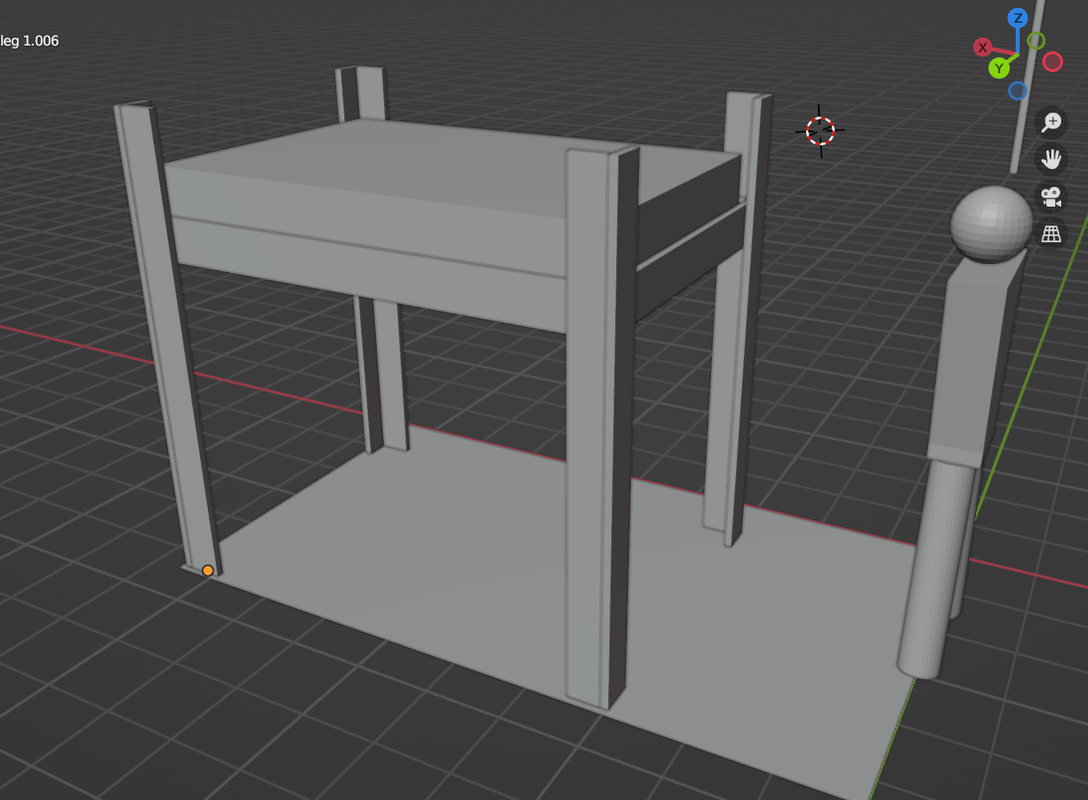

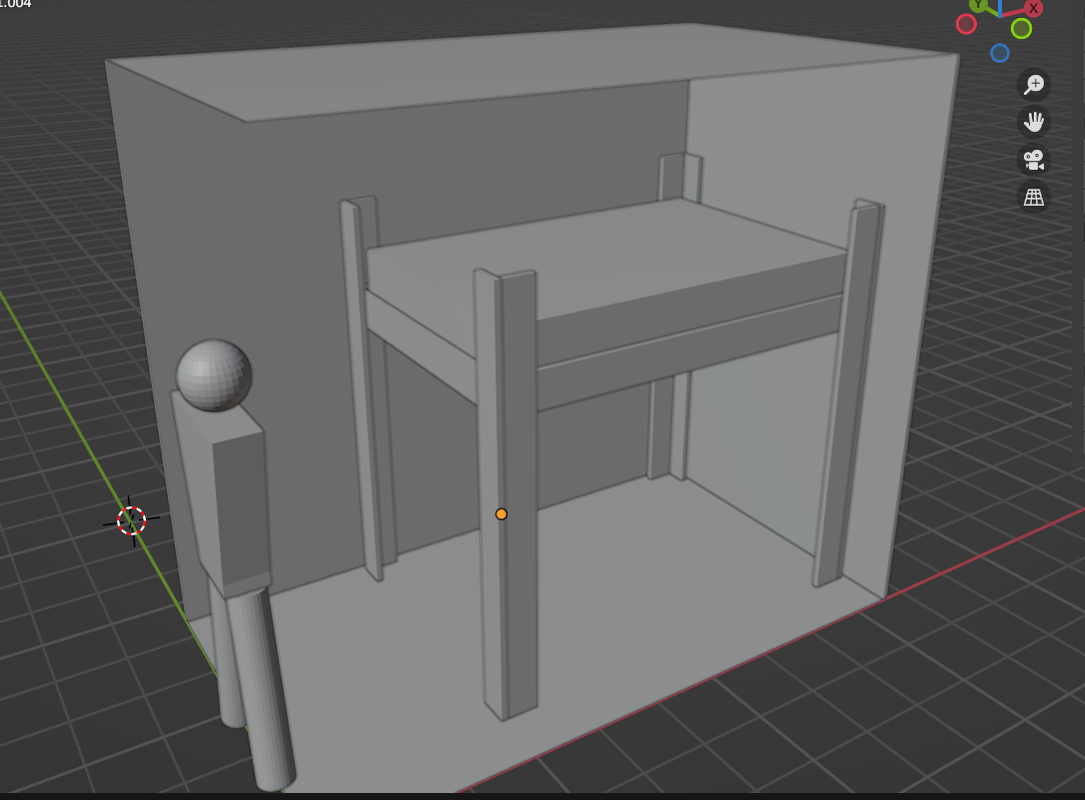

I'm hoping that I can get some general advice here (and obviously I'm not going to hold anyone to any advice given on here, I am responsible for my own work). I'm just designing a loft bed for a room in my house. I built one before many years ago but I'm trying to put a bit more thought in to this one and not 'over engineer' it. What I really want to know is how best to gauge what size wood to use for the legs and the frame itself?

The mattress is a small double - 6' x 4' x 9" apparently about 20kg. I'm looking to have the bottom of the mattress at about 58" height.

Essentially I'm looking to have a frame (sides/ends/slats) and then four L-shaped legs. I'm planning to attach the legs to the frame using coach bolts.

For the legs I'm presently looking at using 32mm x 144mm (finished size) redwood lengths. And I am thinking about 27mm x 170mm for the frame edges. The legs will be approximately 6'3" tall.

My instinct tells me that it's strong enough, but is it possibly more than I need? If anything, I'm concerned about how much weight I'm creating on the floor.

One other thing that I'm wondering about; when building the frame (sides and ends) would a butt joint suffice, or is it better to do something more secure like a dove tail?

Any advice very much appreciated,

H

I'm hoping that I can get some general advice here (and obviously I'm not going to hold anyone to any advice given on here, I am responsible for my own work). I'm just designing a loft bed for a room in my house. I built one before many years ago but I'm trying to put a bit more thought in to this one and not 'over engineer' it. What I really want to know is how best to gauge what size wood to use for the legs and the frame itself?

The mattress is a small double - 6' x 4' x 9" apparently about 20kg. I'm looking to have the bottom of the mattress at about 58" height.

Essentially I'm looking to have a frame (sides/ends/slats) and then four L-shaped legs. I'm planning to attach the legs to the frame using coach bolts.

For the legs I'm presently looking at using 32mm x 144mm (finished size) redwood lengths. And I am thinking about 27mm x 170mm for the frame edges. The legs will be approximately 6'3" tall.

My instinct tells me that it's strong enough, but is it possibly more than I need? If anything, I'm concerned about how much weight I'm creating on the floor.

One other thing that I'm wondering about; when building the frame (sides and ends) would a butt joint suffice, or is it better to do something more secure like a dove tail?

Any advice very much appreciated,

H