devonwoody

Established Member

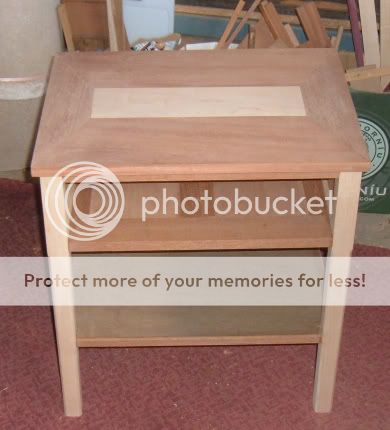

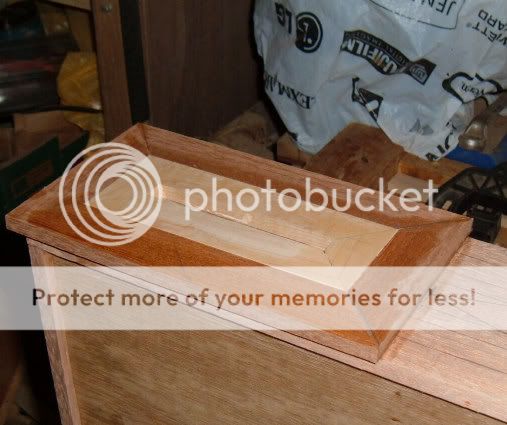

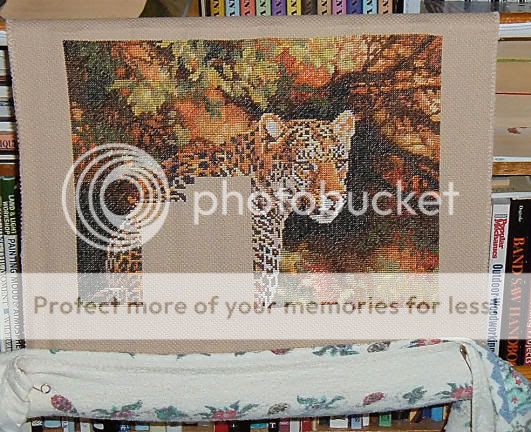

Back on the embroidery table and drawer, however I m becoming spoilt, I cut this corner out of a drawer kicker with the new bandsaw, instead of the japanese hand saw.

Drawer is also partly made and inserted for fit. The front face of drawer will be decorated in my usual manner.

Drawer is also partly made and inserted for fit. The front face of drawer will be decorated in my usual manner.