devonwoody

Established Member

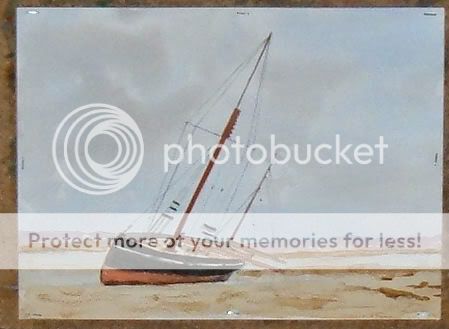

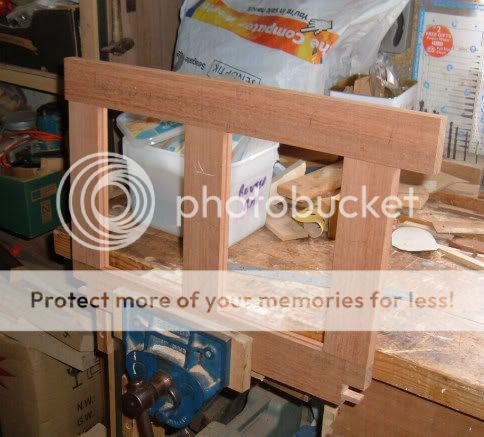

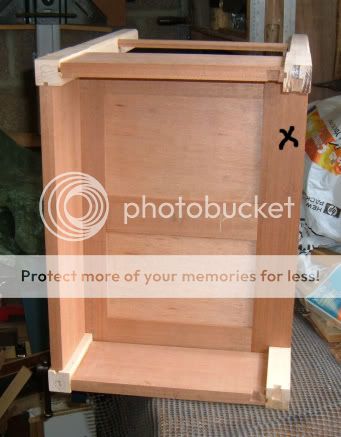

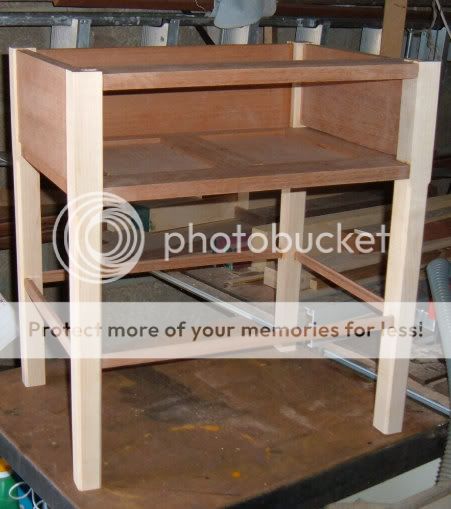

I made this table around two years ago for the wife to store her laptop and tools, it has been a success and the family have all liked it. So another similar table is now under construction for embroidery use and a further table at a later date hopefully so that all our children get one without favour at a later date.

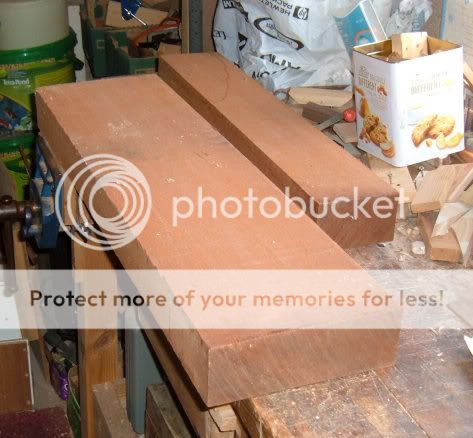

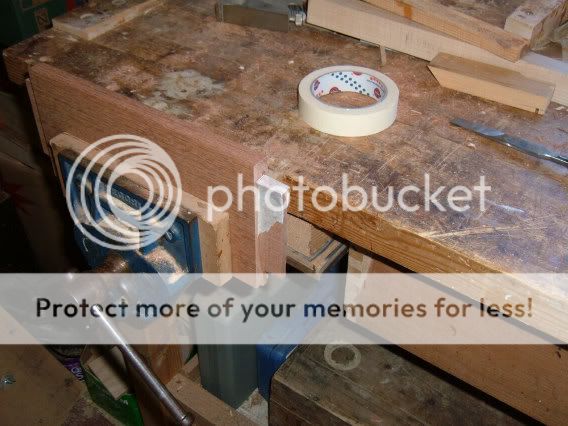

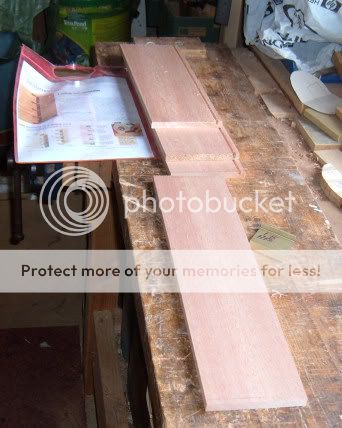

So got out a piece of maple for the legs and ripped off a length which is just right for two sets of legs. Put to my Mitre saw and chopped down 80mm which was just about the maximum capacity of this saw of mine.

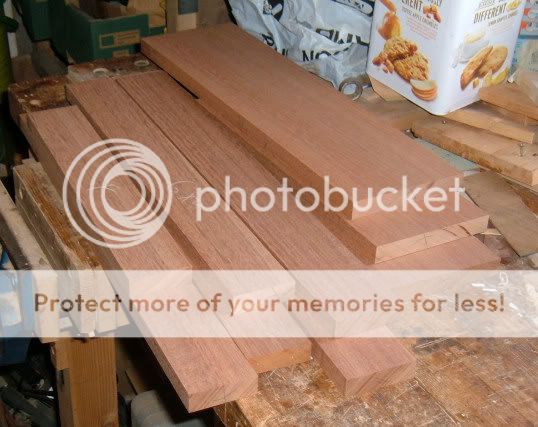

Then finished the session with four legs and just that bit of waste left which means another TB is on the cards.

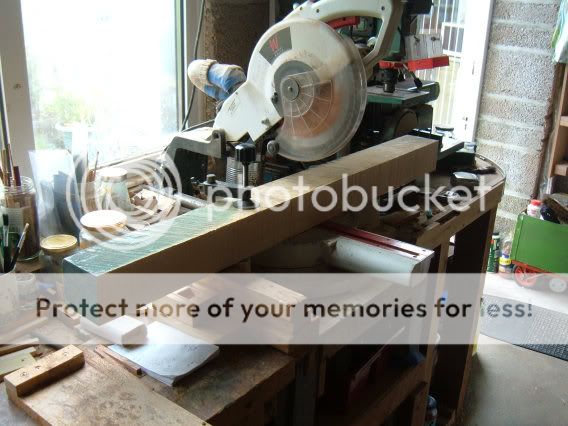

So got out a piece of maple for the legs and ripped off a length which is just right for two sets of legs. Put to my Mitre saw and chopped down 80mm which was just about the maximum capacity of this saw of mine.

Then finished the session with four legs and just that bit of waste left which means another TB is on the cards.