You could say that about any gauge, surely? The geometry isn't any different?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cutting gauge recommendations

- Thread starter sihollies

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bugbear

Established Member

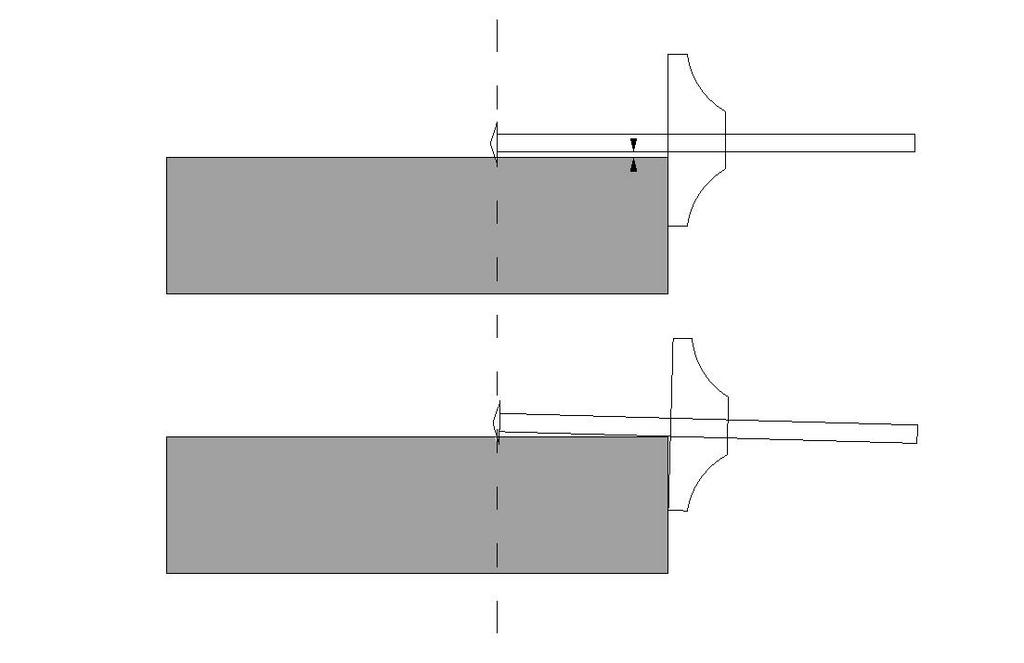

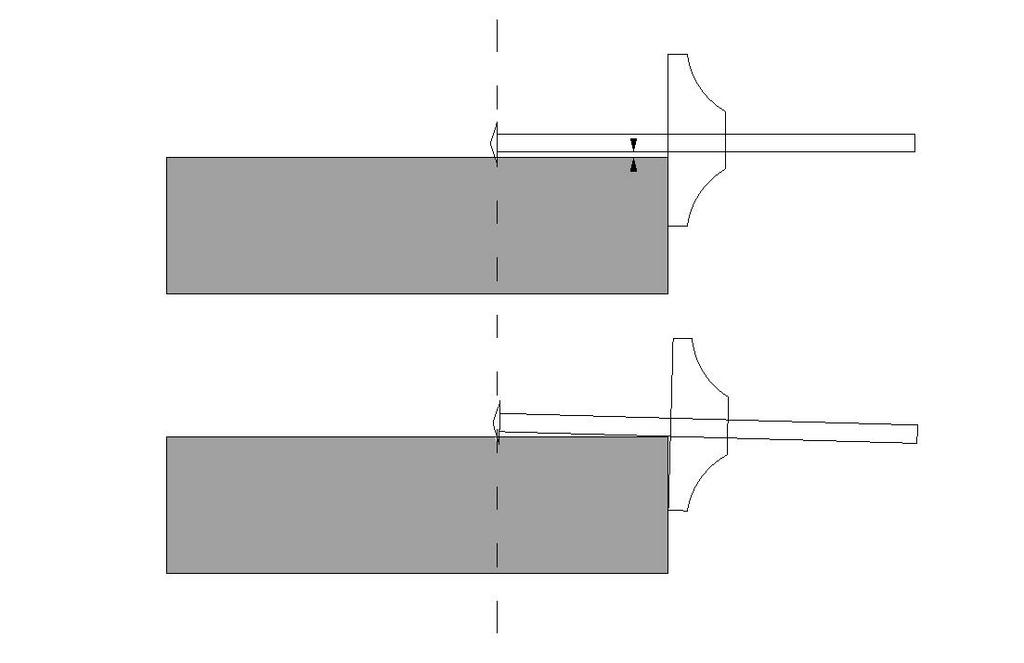

There is (clearly) an error. Have you estimated the size of the error?MikeG.":1ncdpjm2 said:I've said it before, I'll say it again: wheeled gauges are inherently inaccurate unless the wheel is so small that its entire depth is buried into the timber.

BugBear

bugbear

Established Member

In other gauges, it's normal to roll the stem so the cutter only just touches. If (as you imply) the cutter just stuck out vertically, yes, you'd get the same problem.phil.p":9zx3zj0y said:You could say that about any gauge, surely? The geometry isn't any different?

BugBear

MikeG.

Established Member

phil.p":2uo8a7zb said:You could say that about any gauge, surely? The geometry isn't any different?

As bugbear says, you lay a pin-type gauge down so that the shaft is on the work, and the pin "dragging". This option isn't available if there is a wheel on the end of the shaft.

MikeG.

Established Member

bugbear":2d6annq5 said:There is (clearly) an error. Have you estimated the size of the error?MikeG.":2d6annq5 said:I've said it before, I'll say it again: wheeled gauges are inherently inaccurate unless the wheel is so small that its entire depth is buried into the timber.

BugBear

That would vary with the length of the exposed shaft and the diameter of the cutting wheel. When trying to use a wheeled gauge in marking out large mortises in green oak, the line I marked waved around all over the place. It isn't just that error shown by the diagram, but the fact that you don't have a firm register to resist the pull of grain trying to take the wheel off goodness-knows-where. I can see that the things might have a place, but it isn't on big work.

Hell! you could drive a bus through that! :lol:

MikeG.

Established Member

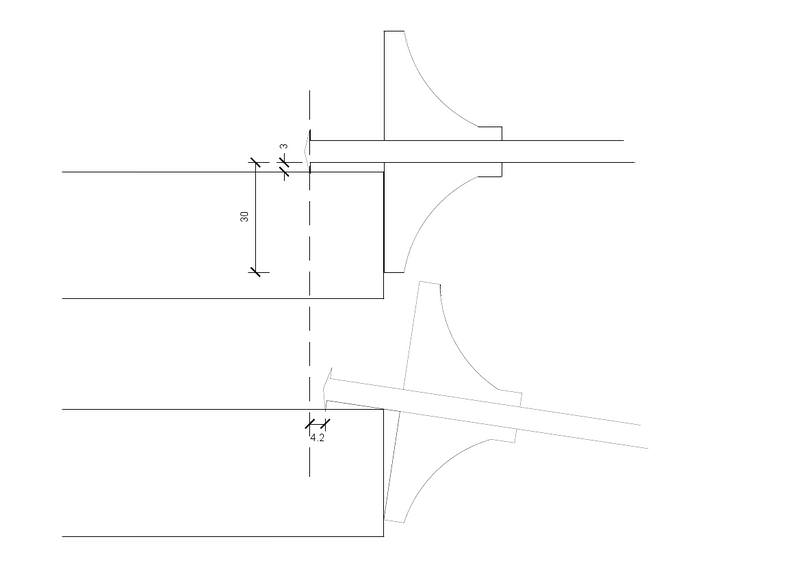

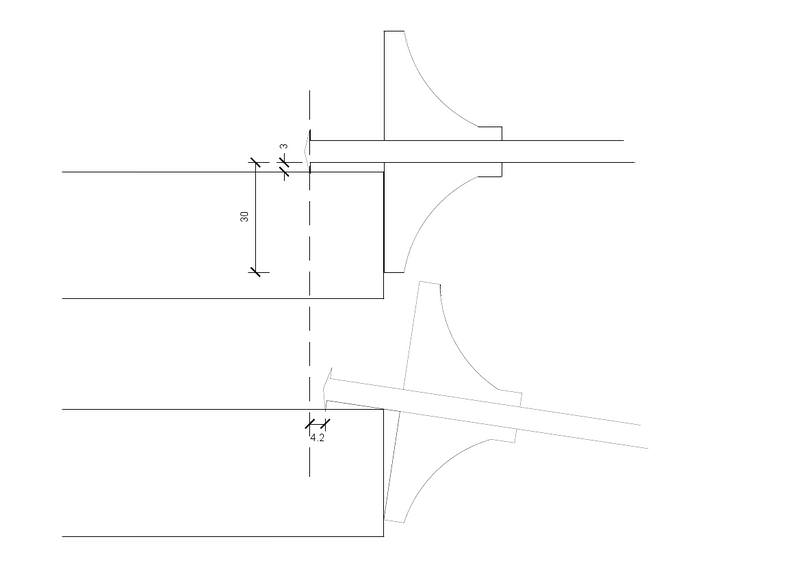

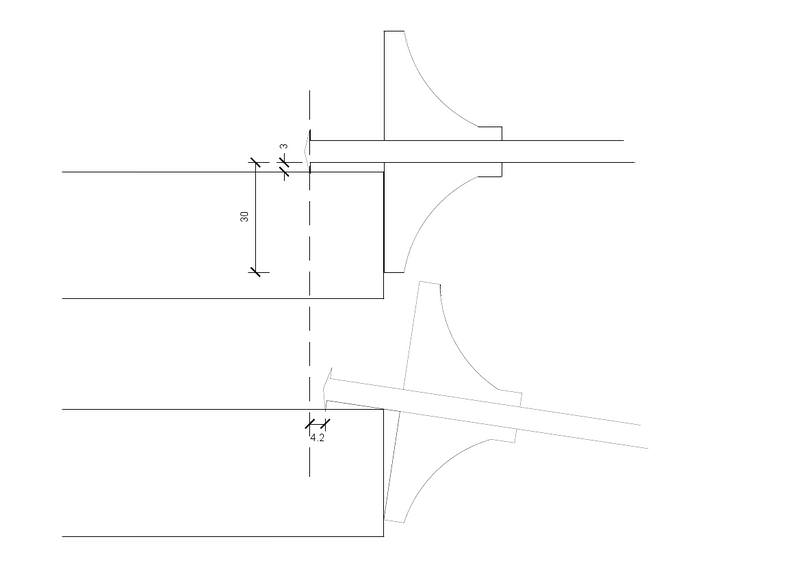

My wheel is at least 3mm bigger in radius than the shaft. Radius. The other critical measurement is the radius of the fence, because it is that which determines how far the shaft has to go before it is touching the face of the timber. I have just drawn that scenario you describe, Pete, but with a 3mm gap at the wheel and a 60 diameter fence, and the error is 4.2mm. Four mm over 20!!

Racers

Established Member

- Joined

- 22 Apr 2005

- Messages

- 9,172

- Reaction score

- 132

I was forgetting the tilting action of the face of the gauge.

But the tilt is amplified by the length of the stem and is easily visable, I tilted one of my gauges to give 4-5mm error and the end of the stem was about 40mm from 90 deg, easily visable and corrected.

I guess any gauge used incorrectly will give errors, but it’s easy to visually align the stem at aproxamatly 90deg to reduce the error to an acceptable amount.

Pete

But the tilt is amplified by the length of the stem and is easily visable, I tilted one of my gauges to give 4-5mm error and the end of the stem was about 40mm from 90 deg, easily visable and corrected.

I guess any gauge used incorrectly will give errors, but it’s easy to visually align the stem at aproxamatly 90deg to reduce the error to an acceptable amount.

Pete

MikeG.

Established Member

That's the point, Pete. There is no reference, as there is with a pin gauge. You have to hold it roughly horizontal by eye. So when an errant bit of grain gets hold of the wheel, you've got nothing to resist it. Fine, it doesn't happen across grain, but it happens all the time along the grain.

MattRoberts

Established Member

I think you'll find that the bevel on the wheel is facing in the other direction, helping to ensure that any pull from errant gain will naturally pull the fence against the piece.

You've got to wonder though, if they're so prone to inaccuracy, why are they made by some of the biggest brands?

You've got to wonder though, if they're so prone to inaccuracy, why are they made by some of the biggest brands?

MikeG.

Established Member

You're right about the cutter. It's only a quick diagram. However, the real life counter to that is that no matter which way around the cutter is the thing waggles around all over the place (in a way which a pin gauge doesn't) when marking with the grain in a piece of green oak. So badly, that I had to clean the face off and start out marking from scratch. Now, I'm reasonably competent, and have been marking out mortises forever. I immediately swapped back to my nearly-knackered old rosewood thing and scored the line straight.

I thought the whole point in marking gauges is to keep it pushed in tight to the wood. I think you'd feel it was unsteady if it wasn't held in tight.

I've had various pinned gauges over the years, a couple rather expensive wheel gauges which weren't the easiest to get on with and finally some discounted Rutlands wheel gauges for around 8 quid each. They really are a pleasure to use ! I've been hanging a lot of sash's lately roughly 300 hinge housings. I chose marking gauges and butt chisels over the hinge router jig. I'd get rid of all my pinned and expensive wheel gauges if it meant I could keep the Rutlands offering .

Sent from my SM-G900F using Tapatalk

I've had various pinned gauges over the years, a couple rather expensive wheel gauges which weren't the easiest to get on with and finally some discounted Rutlands wheel gauges for around 8 quid each. They really are a pleasure to use ! I've been hanging a lot of sash's lately roughly 300 hinge housings. I chose marking gauges and butt chisels over the hinge router jig. I'd get rid of all my pinned and expensive wheel gauges if it meant I could keep the Rutlands offering .

Sent from my SM-G900F using Tapatalk

Geordie Joe

Established Member

MikeG.":t8sqku3f said:My wheel is at least 3mm bigger in radius than the shaft. Radius. The other critical measurement is the radius of the fence, because it is that which determines how far the shaft has to go before it is touching the face of the timber. I have just drawn that scenario you describe, Pete, but with a 3mm gap at the wheel and a 60 diameter fence, and the error is 4.2mm. Four mm over 20!!

I see your problem, you're not pushing the fence against the wood!

Seriously, I think you are assuming that everyone who uses a pin gauge uses it correctly, and everyone who uses a wheel gauge uses it wrong.

I use both types and I would notice if my lines were off by that much. I have just popped out and tried to recreate your picture, and you can't do it unless you use the gauge in a way that is so wrong even a first time user would know it was wrong.

In my experience, as long as you keep the intersection of the shaft and the face on the corner of the wood then slight angle of the shaft is offset by the slight angle of the wheel.

MikeG.

Established Member

ColeyS1":1fmaqx9q said:I thought the whole point in marking gauges is to keep it pushed in tight to the wood.....

Of course. However, if you push it in hard but have no reference for the height at which you hold it above the face of the wood, it is (to my mind) an utterly unnecessary variable which can and does cause issues.

MikeG.

Established Member

Geordie Joe":3hm7dncv said:.......as long as you keep the intersection of the shaft and the face on the corner of the wood.......l.

That's actually physically impossible with squared stock, unless the cutting wheel is buried all the way up to the shaft.

(Edit....or, for the pernickity, if you have stock of zero thickness

MikeG.

Established Member

Geordie Joe":28mjhzto said:......In my experience, as long as you keep the intersection of the shaft and the face on the corner of the wood then slight angle of the shaft is offset by the slight angle of the wheel.

Actually, on thinking about this some more, this beautifully illustrates my case. If you tilt the gauge as you describe such that the shaft is sitting on the surface of the wood (as per my lower image), then the face of the fence is only touching the edge of the stock at one point: the bottom of the round face. You don't have any reference at all then. Looking down from above the gauge would be free to wave backwards and forwards, with absolutely nothing to keep it at right angles to the edge of the workpiece.

There is a way of making it work well every time with wood which is likely to deflect that cutting wheel and that is to use it as a two handed tool. I caught myself doing it instinctively this afternoon while doing a fairly critical marking for thickness. I clamped the wood in the vice, had my right hand in the normal position and the left steadying it. It works a treat. I always do that with e.g. pine where the grain really does grab at the cutting wheel and of course with such wood the first cut has to be very light in any event.MikeG.":22ptalyz said:That's the point, Pete. There is no reference, as there is with a pin gauge. You have to hold it roughly horizontal by eye. So when an errant bit of grain gets hold of the wheel, you've got nothing to resist it. Fine, it doesn't happen across grain, but it happens all the time along the grain.

On a lot of well behaved hardwoods there tends to be no such problem and in such cases it is easy to keep it horizontal by eye.

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 8

- Views

- 2K