We are into mechanics here!

Torque is a twisting force.

A twisting force of 1lb applied at a radius of 1ft gives 1lbft

At a radius of 2ft gives 2lbft etc etc.

The Yankees uses a push action which generates an incremental torque as the handle is pushed down.

So in this case the longer the handle the more torque is generated.

In the "locked" state the Yankee's torque is only dependent on the twisting force applied at the handle - the bigger the handle ( and therefore the radius) the greater the torque.

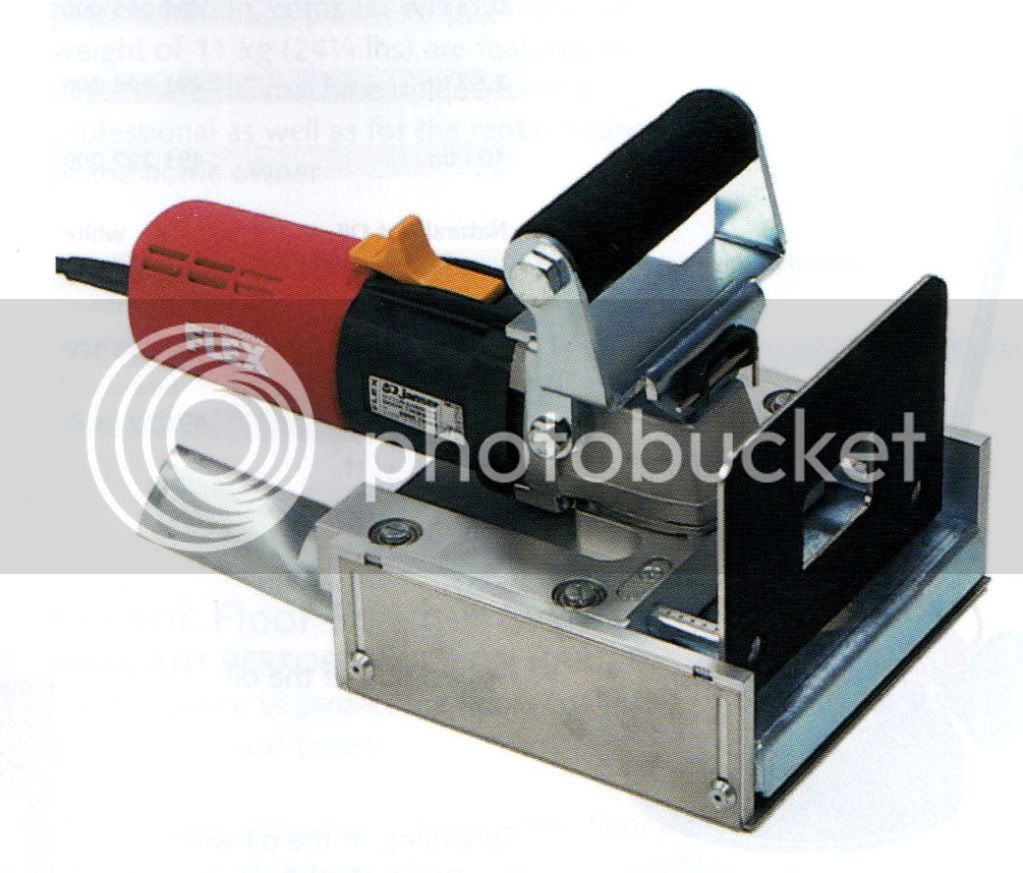

Clamp a Molewrench to a screwdriver and you can generate a tremendous torque

Rod

Torque is a twisting force.

A twisting force of 1lb applied at a radius of 1ft gives 1lbft

At a radius of 2ft gives 2lbft etc etc.

The Yankees uses a push action which generates an incremental torque as the handle is pushed down.

So in this case the longer the handle the more torque is generated.

In the "locked" state the Yankee's torque is only dependent on the twisting force applied at the handle - the bigger the handle ( and therefore the radius) the greater the torque.

Clamp a Molewrench to a screwdriver and you can generate a tremendous torque

Rod