Personally I wouldn't glue a cramping block on to the apron, at least not for this particular job. Removing the cramping block can take a few whiskers of wood fibres from the apron (or at the very least leave some residue) dealing with these requires a clear run for you to get a plane onto the job. But that small 3mm reveal you've got at the leg prevents that, and even if it's flush you don't want to risk shaving out cross grain on the leg.

Consequently I'd glue 45 degree cramping blocks onto a strip of ply or a bit of scrap, and cramp that onto the apron.

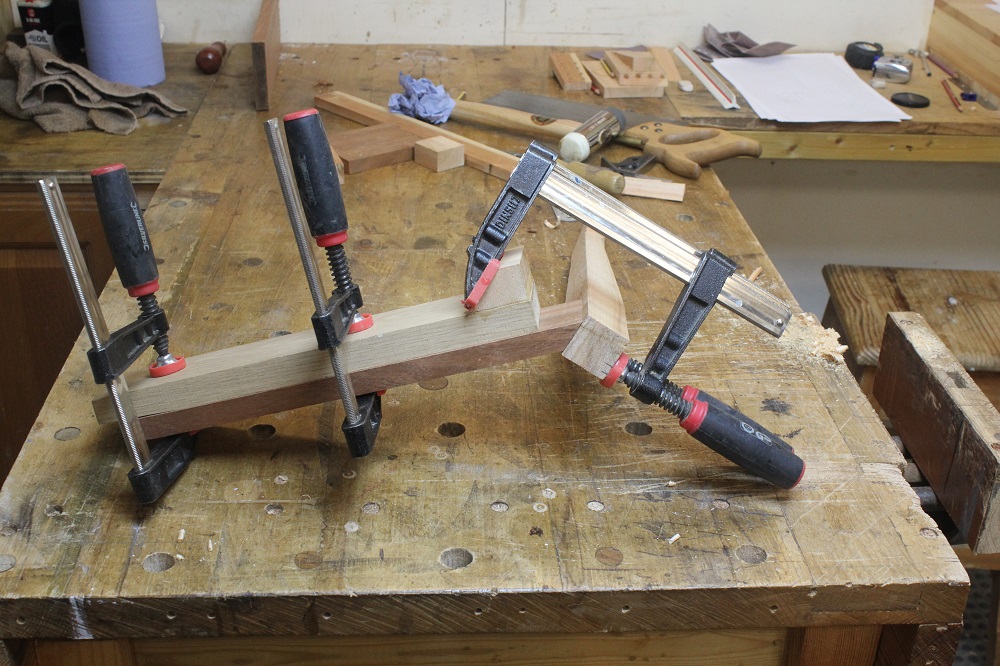

These photos illustrate the general principle, say these bits of scrap represent the leg and the apron,

Here's the cramping block, this is a commercial version, but you could make your own and have a 45 degree block instead of a circle, the key thing is the block is now cramped on rather than glued on,

And here's glue-up pressure being applied across the joint,