Go for it - everyone needs to - just go to a decent timber merchant for PAR and forget CLS at B&Q, Wickes and so on. Don't start by deliberately making hard work.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a workbench out of softwood?

- Thread starter PennineRider

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

novocaine

Established Member

it's your first bench, you build it from what you have.

Bodgers

Established Member

Where's the love for a hardwood bench? You can get Beech fairly cheap from some small timber yards...

I my first bench is made from a combination of the best bits of CLS I could dig out from a local Howarth Timber, but that's become more of a place to put things At some point this year I was going to build a 'proper' bench from Beech.

At some point this year I was going to build a 'proper' bench from Beech.

Sent from my iPad using Tapatalk

I my first bench is made from a combination of the best bits of CLS I could dig out from a local Howarth Timber, but that's become more of a place to put things

Sent from my iPad using Tapatalk

Jacob

New Luddism. Awake and resist!

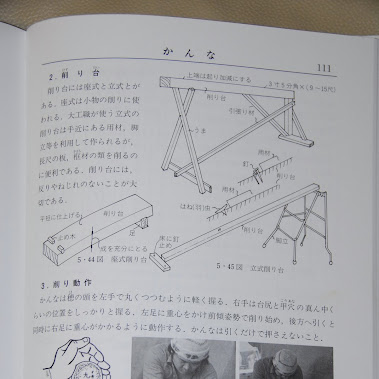

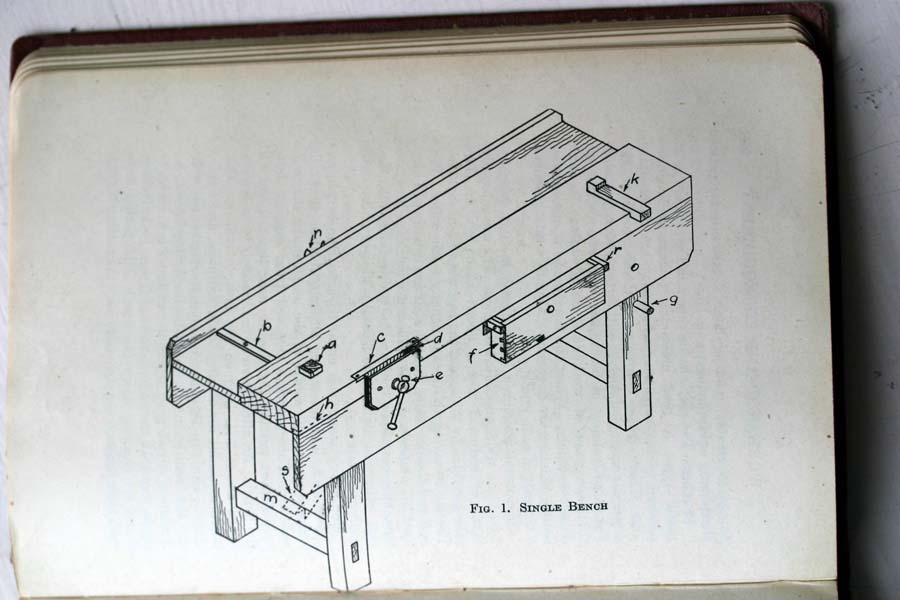

Just a detail but for the trad bench (below) you only need one piece of beech. Two makes it a double sided such as you would see in schools and other establishments - a vice at each end on opposite sides.MusicMan":1g5hfdae said:I used a timber yard for two 12x3 slabs of beech for the top, and had no trouble getting them to run it through their big planer/thicknesser for me.

A basic bench is one big piece of timber which you can work on and has enough inertia, like the japanese planing beam, but with various configurations and add ons. At its simplest a large piece of timber resting with one end raised on a low support.

georgemharris

Member

Hi folks,

First time posting

I watched this series of vids by Paul Sellers a while back and he discusses the idea of building your workbench from hard and softwoods, then proceeds to build his from PAR softwood. I think you could take that a as a ringing endorsement of the idea!

Here's a link to the video series. One of the nice things about it is that he assumes you don't have a workshop or bench, and does it all in his garden, with very minimal tools, only a no4 plane and two saw horses. Very impressive.

Enjoy

youtube playlist no PLD39949332C7FB168

First time posting

I watched this series of vids by Paul Sellers a while back and he discusses the idea of building your workbench from hard and softwoods, then proceeds to build his from PAR softwood. I think you could take that a as a ringing endorsement of the idea!

Here's a link to the video series. One of the nice things about it is that he assumes you don't have a workshop or bench, and does it all in his garden, with very minimal tools, only a no4 plane and two saw horses. Very impressive.

Enjoy

youtube playlist no PLD39949332C7FB168

mugginsNO1

Established Member

Building your first bench really depends on ones needs at the time. For me, I needed something robust and sturdy that I could build quickly. The cost was secondary. Having a plywood top meant I was using it within two days of starting construction. When/if I ever have more time, I'd love to build a more traditional version with a couple of really good vices. Something like a Maguire........one day.

graduate_owner

Established Member

Has anyone tried making their bench from plywood laminations glued together? It looks like an interesting method, especially if you are not too handy at cutting mortices ( or don't have a bench to work at for cutting mortices?).

K

K

Jacob

New Luddism. Awake and resist!

Except he completely omits any reference to the standard traditional British bench as found in schools colleges and wood work places everywhere. It's a major omission - the trad bench is far and away the best and easiest beginners bench and if your first one is any good you will probably never need another. Sellers version is a good.jnw010":2imfn51h said:Chris Schwartz has done a couple of excellent books on workbench designs. He doesn't just tell you what to do, but presents designs and features, explaining the pro's and cons. Well worth a read.

Schwarz has something he calls the "English" bench but it's a figment of his imagination and not a good starting point.

PS I've only seen one book - has he done two?

Ttrees

Iroko loco!

Some nice benches folks

Me being a scavenger, I fail to see why anyone would need to buy softwoods atall :?

but if you insist, you still need a bench to work on, if you want to get a good results, and understand the hand plane

a lot quicker than fighting with it for no reason

Find a fire door from a skip, and work to that ...ie use it as a reference, as it will be suitable to

plane on, if you make it secure, for the time being.

Dont affix it down so tight as to flex this fire door because its...

1 rigid (won't deflect if supported correctly)

2 flat, (necessary for learning hand planing with speed, ease, precision and understanding), gained by

not by watching and repeating, someone planing timber using a vise, and just matching two pieces together, thats for building sites that kinda thing.

3 stable, (as in it wont warp as you can get with solid timber contracting or expanding), more,so with softwoods, but that can be even more problematic if you fasten it with screws, nails, or dowels without any sort of planning ... so its common to have brackets instead with slots in them to account for this movement,

Good luck

Jacob, I'm surprised you have such a narrow surface for working on

Me being a scavenger, I fail to see why anyone would need to buy softwoods atall :?

but if you insist, you still need a bench to work on, if you want to get a good results, and understand the hand plane

a lot quicker than fighting with it for no reason

Find a fire door from a skip, and work to that ...ie use it as a reference, as it will be suitable to

plane on, if you make it secure, for the time being.

Dont affix it down so tight as to flex this fire door because its...

1 rigid (won't deflect if supported correctly)

2 flat, (necessary for learning hand planing with speed, ease, precision and understanding), gained by

not by watching and repeating, someone planing timber using a vise, and just matching two pieces together, thats for building sites that kinda thing.

3 stable, (as in it wont warp as you can get with solid timber contracting or expanding), more,so with softwoods, but that can be even more problematic if you fasten it with screws, nails, or dowels without any sort of planning ... so its common to have brackets instead with slots in them to account for this movement,

Good luck

Jacob, I'm surprised you have such a narrow surface for working on

Jacob

New Luddism. Awake and resist!

It's not narrow - it's a 30" wide bench with a well. Nearly everything gets done on the front beam, or spans to the back. It's normal, tried and tested. It's the size for joinery and furniture. If you were regularly doing smaller stuff then a flat table might be better, but I can always lay a board over the well instead.Ttrees":34hkx8eu said:....

Jacob, I'm surprised you have such a narrow surface for working on

Ttrees

Iroko loco!

I was thinking you might have done that a few times with the tool well.

I would need a cover, and flat at that! , if I was expected to be working on a door panel or something, as

I use the bench for reference, and employ techniques like rocking, pivoting, candling, abrasion "witness" marking

using a square frequently and having it positioned in or near situ for dragging over

probably other things also.

Do you not think its more faff to have to sight everything all the time, instead of employing these above centuries old techniques

Maybe, you use machines and know your stock is true, so you are just taking final swipes on everything...

That's the only way I could see that working for me

Thanks

Tom

I would need a cover, and flat at that! , if I was expected to be working on a door panel or something, as

I use the bench for reference, and employ techniques like rocking, pivoting, candling, abrasion "witness" marking

using a square frequently and having it positioned in or near situ for dragging over

probably other things also.

Do you not think its more faff to have to sight everything all the time, instead of employing these above centuries old techniques

Maybe, you use machines and know your stock is true, so you are just taking final swipes on everything...

That's the only way I could see that working for me

Thanks

Tom

Jacob

New Luddism. Awake and resist!

Actually hardly ever need to cover it at all. A bit back I had some 20" square panels to plane and sand and did them on a bit of chipboard with laths on all four sides as stops. Draped cloth over to protect the underside from picking up marks. Probably would have done the same even if it had been a full width table.Ttrees":1o4mey4e said:I was thinking you might have done that a few times with the tool well.

I would probably need a cover, and flat at that! , if I was expected to be working on a door panel or something.

Thanks

Tom

Sighting everything all the time sounds a lot easier than what you describe! Squint along the grain for straightness, tilt edge of plane over the width for hollows, or combi square blade.

I'd never use the bench for reference, though if necessary it's much easier to level the two sides of a bench with a well, against each other, rather then levelling a single table top. So if levelling bench is your thing the ideal would be this below, with a simple rail at the back to level against the beam at the front

Mr T

Established Member

graduate_owner":1o7qf50c said:Has anyone tried making their bench from plywood laminations glued together? It looks like an interesting method, especially if you are not too handy at cutting mortices ( or don't have a bench to work at for cutting mortices?).

K

You might be interested in this https://www.ukworkshop.co.uk/forums/six-tool-bench-t106170.html

I have to admit to being a bit ignorant about softwood. Can someone explain the difference between PAR and PSE for me? I have always bought PSE which is planed on all faces. Is PAR the stuff with rounded corners?

Chris

Basically the same. The rounded edged stuff is CLS - Canadian Lumber Standard.

Paul200

Established Member

It only seems a minefield because everyone chimes in with their own ideas of perfection (you did ask!) and muddies the water. Your original proposal sounds fine to me - a lot better than my first bench (a 2x2 frame with 18mm MDF top!). I would seriously recommend buying the timber anywhere but B&Q though.PennineRider":2z8tx8hw said:OK well it sounds like a minefield so I'm not going to bother.

Thanks all

I'm currently building my first 'proper' bench from 4x2 DAR (PAR in England) Redwood. The timber came from a local independent supplier who, when I told him what it was for, hand selected the less knotty lengths for me - don't get service like that in B&Q! The design is mine, based on what I know I need from it. It doesn't have a deep apron, doesn't have a well, does have a split top and will no doubt develop over the years. And I'm thoroughly enjoying the build!

Don't give up - go for it! Make your bench your way, learn from it and how you use it and eventually it will either develop into what you need or you can start again when you know what you want - but definitely build it, your ideas are sound.

Cheers

Paul

MattRoberts

Established Member

This thread is from Feb last year guys...

Similar threads

- Replies

- 23

- Views

- 2K