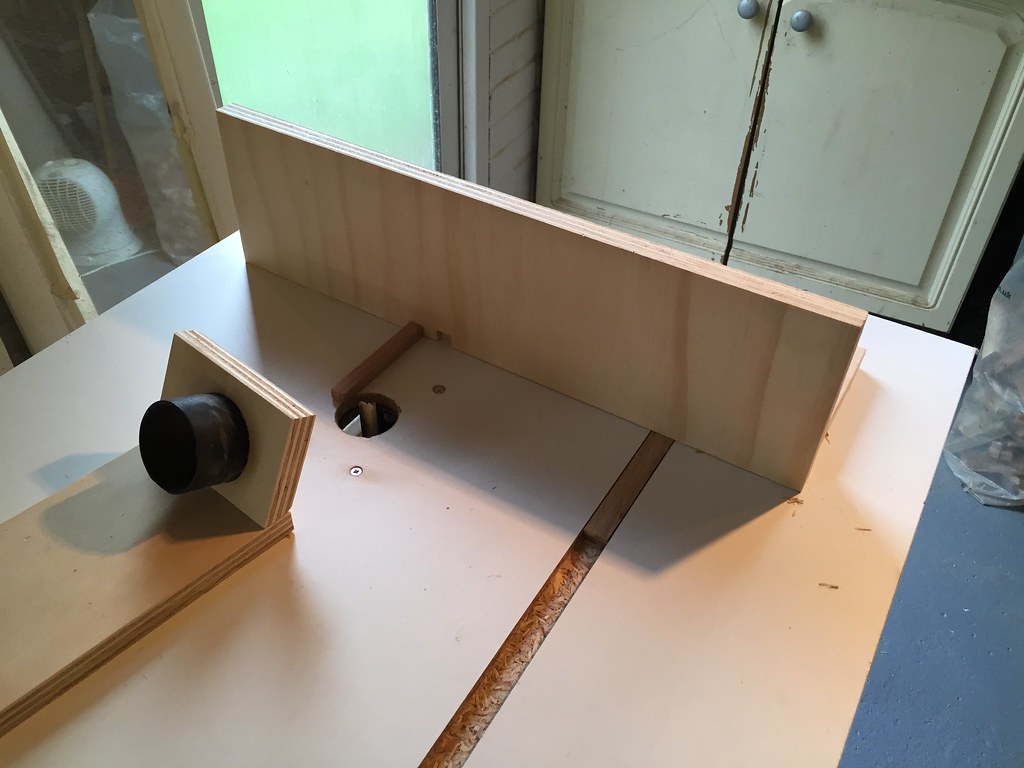

Apologies for the huge image, posting a photo from my mobile is trickier than I thought!

After many weeks of faffing about making a router table and a box joint jig, I finally have something that resembles a box joint!

It's half inch fingers and, aside from them being a little too deep the fit is very nice.

Though the fingers do give a fairly tight joint you can see small gaps between the fingers. If I wanted an absolutely perfect joint would I be expected to cut the fingers wider and then 'drive' the fingers together with a clamp for a very tight finish?

After many weeks of faffing about making a router table and a box joint jig, I finally have something that resembles a box joint!

It's half inch fingers and, aside from them being a little too deep the fit is very nice.

Though the fingers do give a fairly tight joint you can see small gaps between the fingers. If I wanted an absolutely perfect joint would I be expected to cut the fingers wider and then 'drive' the fingers together with a clamp for a very tight finish?