G S Haydon

Established Member

- Joined

- 24 Apr 2013

- Messages

- 1,667

- Reaction score

- 222

Sharpen and use.

You can see 4 1/2 on the front by the knob on the last two photos.MikeG.":3kjauz2u said:You sure that's a 4-1/2, and not a 4? It looks identical to mine, which is a 4.

Common as muck. Great plane. Shaapen it, set it, and use it. If it doesn't work properly, find out why and fix it. It's a tool, not an objet d'art.

MikeG.":1zoyhmc8 said:phil.p":1zoyhmc8 said:I was skeptical about P.S's oil can - but it works perfectly and is safer than leaving vegetable oils hanging around. ......

I've used the same stub of candle for about 20 years now. A quick zig zag on the bottom of the plane is all you need.

MJP":38rvdt9k said:"Would it be completely sacrilege to completely replace the Japanning, lap the sole and maybe even replace the totes etc.?"

and in doing so totally erase its history?

I think so.

Bm101":1jazotsa said:You might have to open the mouth with a file to fit the new iron Bodgers. Are the benefits of pmv advantageous over any difficulties of maintaining a thick iron compared to the original iron? No answers here... Just a thought since no one's mentioned it. :wink:

All the best. Don't get overwhelmed with all the answers pal. It's your plane.

Regards,

Chris

Bm101":a5gufeio said:You might have to open the mouth with a file to fit the new iron Bodgers. Are the benefits of pmv advantageous over any difficulties of maintaining a thick iron compared to the original iron? No answers here... Just a thought since no one's mentioned it. :wink:

All the best. Don't get overwhelmed with all the answers pal. It's your plane.

Regards,

Chris

Bodgers":1ngv0bdo said:I bought this Stanley 4 1/2 smoother for £30 delivered - which seems like an ok price to me. I could have gone cheaper, but I didn't want to buy a total basket case.

The sole is basically flat apart from a sort of very slightly shallow area at the back. So I might at least do a bit of flattening there. Blade needs some attention as it has some minor chips - maybe a regrind.

A little bit crazy, but alongside the Shooting plane I just ordered from Lee Valley, I bought a Veritas PMV11 blade and chip breaker for a 4 1/2 or 5 1/2. I thought I would use it on this or maybe even a future used 5 1/2 buy. Those won't be here until late March when the relatives bring those over.

I wasn't going to do much with this plane, but as I have sunk £90 into this now (with the fancy Veritas blade) I was thinking of giving this plane a full refurb.

The Japanning is basically ok but there are chips in some areas. The handles/tote are in tact but the finish is poor and there are some chips.

Would it be completely sacrilege to completely replace the Japanning, lap the sole and maybe even replace the totes etc.?

Jacob":1ppbvhdp said:If in good usable condition they tend to fetch a better price is they haven't been worked over by an enthusiast.

That is a sweet looking Bedrock. I wanted the 4 1/2 in the Bedrock, but I just couldn't find one at a cost that didn't make it look crazy buying it over a QuangSheng pattern Bedrock.Bodgers":2peew746 said:I bought this Stanley 4 1/2 smoother for £30 delivered - which seems like an ok price to me. I could have gone cheaper, but I didn't want to buy a total basket case.

The sole is basically flat apart from a sort of very slightly shallow area at the back. So I might at least do a bit of flattening there. Blade needs some attention as it has some minor chips - maybe a regrind.

A little bit crazy, but alongside the Shooting plane I just ordered from Lee Valley, I bought a Veritas PMV11 blade and chip breaker for a 4 1/2 or 5 1/2. I thought I would use it on this or maybe even a future used 5 1/2 buy. Those won't be here until late March when the relatives bring those over.

I wasn't going to do much with this plane, but as I have sunk £90 into this now (with the fancy Veritas blade) I was thinking of giving this plane a full refurb.

The Japanning is basically ok but there are chips in some areas. The handles/tote are in tact but the finish is poor and there are some chips.

Would it be completely sacrilege to completely replace the Japanning, lap the sole and maybe even replace the totes etc.?

Bodgers, you can do what you like - it is your plane. I actually get that you want something a little blingy to go with the new Veritas that is on its way. And why not? It is just a plane, a tool, and yours to use. Some like them old and dingy, and some not. This example is not destined for a museum, and the very best one can hope is that it gives you many years of satisfied use.

Here's a #605 I repainted (use engine paint - it, too, was not a collector's item when I received it) ..

I have also restored others to original condition using jappaning because they were collector's items (such as a Stanley #51/52). Let me know if you want the recipe, but I think an engine spray paint is just fine in your case - but you must remove all vestiges of existing paint, otherwise it will look like hell.

Regards from Perth

Derek

Woody2Shoes":pz6su2p2 said:Bm101":pz6su2p2 said:You might have to open the mouth with a file to fit the new iron Bodgers. Are the benefits of pmv advantageous over any difficulties of maintaining a thick iron compared to the original iron? No answers here... Just a thought since no one's mentioned it. :wink:

All the best. Don't get overwhelmed with all the answers pal. It's your plane.

Regards,

Chris

They sort of have mentioned it already

Bm101":25ccslqq said:Woody2Shoes":25ccslqq said:Bm101":25ccslqq said:You might have to open the mouth with a file to fit the new iron Bodgers. Are the benefits of pmv advantageous over any difficulties of maintaining a thick iron compared to the original iron? No answers here... Just a thought since no one's mentioned it. :wink:

All the best. Don't get overwhelmed with all the answers pal. It's your plane.

Regards,

Chris

They sort of have mentioned it already

I think I probably phrased it badly Woody. Apologies. What I meant by 'no answer here' is no definite answer from me. Willingly hold my hands up to being a novice and as such I'm very cautious about giving out 'advice'. Hence maybe my caution. What I was trying to convey (badly) was what something I'd previously read by Custard. By chance, he's repeated the same advice in a similar thread today so I hope he won't mind me copy and posting it here.

1. The very thick iron means sharpening can be a long and tedious business without a power grinder to handle the majority of the metal removal.

2. The geometry of the iron makes forming and finessing a camber quite a bit harder. Getting a camber just how you want it, and then keeping it there, is one of the most important aspects of plane work. It's not impossible with a low angle jack, but it is much more of a challenge.

3. You can't use a closely set cap iron to control tear out, and the high angle iron you use with your low angle jack may not be high enough to get the job done.

4. There's not much lateral adjustment possible.

Custard's original post is here: topic110742.html It's aimed at a different question so maybe not entirely relevant in its original context.

@ Bodgers. My first ever post on ukw was about fitting a PMV iron to a troubled old record 4 1/2. My first ever woodworking tool (as opposed to diy, etc) I thought, I'll be needing one of them then. I'm hardly any wiser now but I was actually trying to fit it upside down. Really.

So a short history of my beginning to fathom out the workings of a plane and this has no reflection of you in it. Just my experience.

In the end I swallowed my pride and when a stanley came up on here by Graham Haydon for twenty quid I bit his fingers off. It turned up tuned and sharp. I learnt a lot from that plane and on here about the cap iron etc etc. On reflection that was my datum plane. It helped me see how to set up and more importantly adjust it to the particular circumstance I was (quite often vainly and frustratingly) addressing. It's easy to forget just how much you are scrabbling about in the dark when you very first start out. Again, no reflection on you. I have no idea what stage you are at, probably far advanced from me.

I never did fit that pmv iron to that Record and despite the assurances that it will fit most stanleys/records. This one won't. Not without filing the mouth. Hence the cautionary note.

So it's still there, down the shed, on the side. I will at some point fit it on the Record,open the mouth just enough, sort the other issues with that particular plane. Would be madness not to. I have no doubt it's an iron of great metallurgical properties.

Be rude not to.

Would I buy one now?

No I probably wouldn't.

Think I'd prefer to sharpen little and often tbh.

Who knows? Certainly not me. :wink:

Cheers

Chris

Bm101":kf5u707o said:You might have to open the mouth with a file to fit the new iron Bodgers. Are the benefits of pmv advantageous over any difficulties of maintaining a thick iron compared to the original iron? No answers here... Just a thought since no one's mentioned it. :wink:

All the best. Don't get overwhelmed with all the answers pal. It's your plane.

Regards,

Chris

Yep.patrickjchase":kwbz1li2 said:.....

IMO the Stanley irons are thick enough to begin with. If they needed to be thicker for "optimum performance" then they would have been made that way, particularly in the BedRock line which were beefed up in other respects. I've never had a chatter problem with a Stanley iron that couldn't be fixed by properly tuning the plane.

So you are saying PmV11 is 'snake oil'?Jacob":6zhoq5wq said:Yep.patrickjchase":6zhoq5wq said:.....

IMO the Stanley irons are thick enough to begin with. If they needed to be thicker for "optimum performance" then they would have been made that way, particularly in the BedRock line which were beefed up in other respects. I've never had a chatter problem with a Stanley iron that couldn't be fixed by properly tuning the plane.

The whole "refurb aftermarket PMV11..etc" is just a funny little hobby in it's own right and has no bearing on woodwork and tool use.

It's a branch of the steam punk fashion movement.

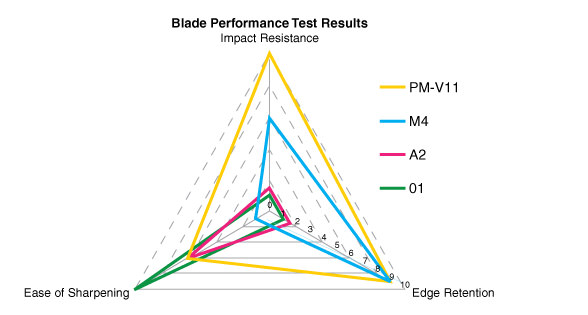

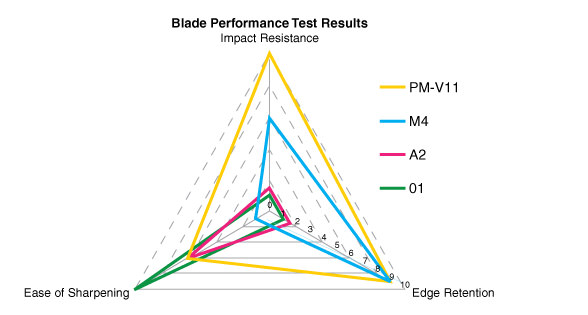

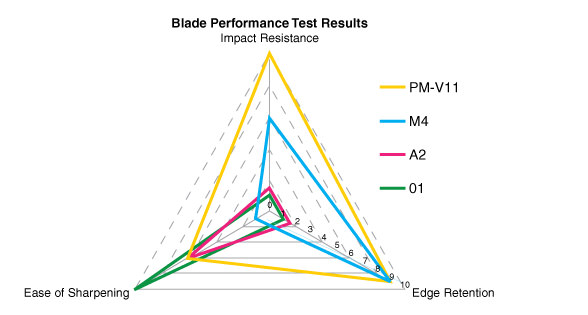

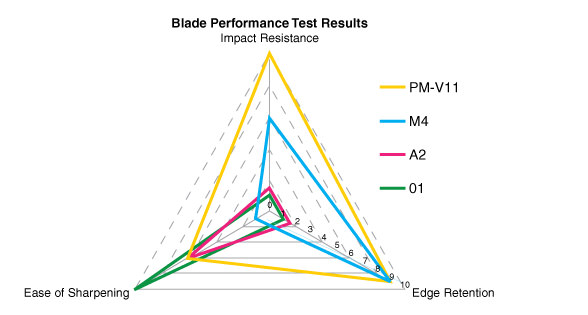

This intriguing but very silly triangular diagram says it all! Fantasy!

Enter your email address to join: