I say finally as if I had been searching a while but in reality it's been a few weeks but felt longer with a few disappointing outcomes on auctions. Mainly because I was previously bidding on well presented examples.

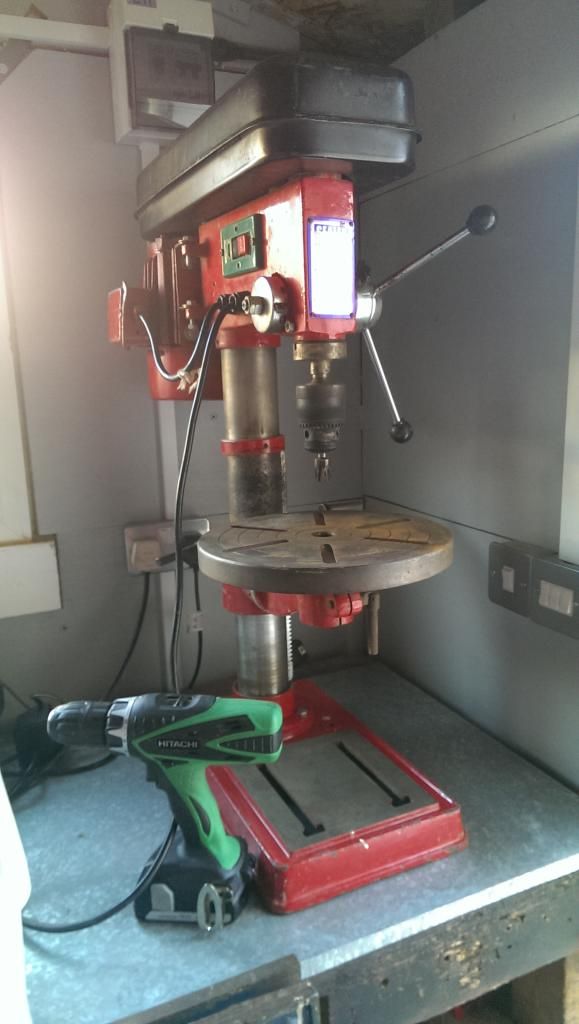

How ever I stumbled across this-

Merely described as pillar drill, no longer required. With a typo of pilar in the title, me being the avid ebayer I always search a couple of a typos too.

So went to pick it up, fella kindly swept off the kilo of saw dust it was under. Personally I clean up an item before even listing but thats why my items sell better.

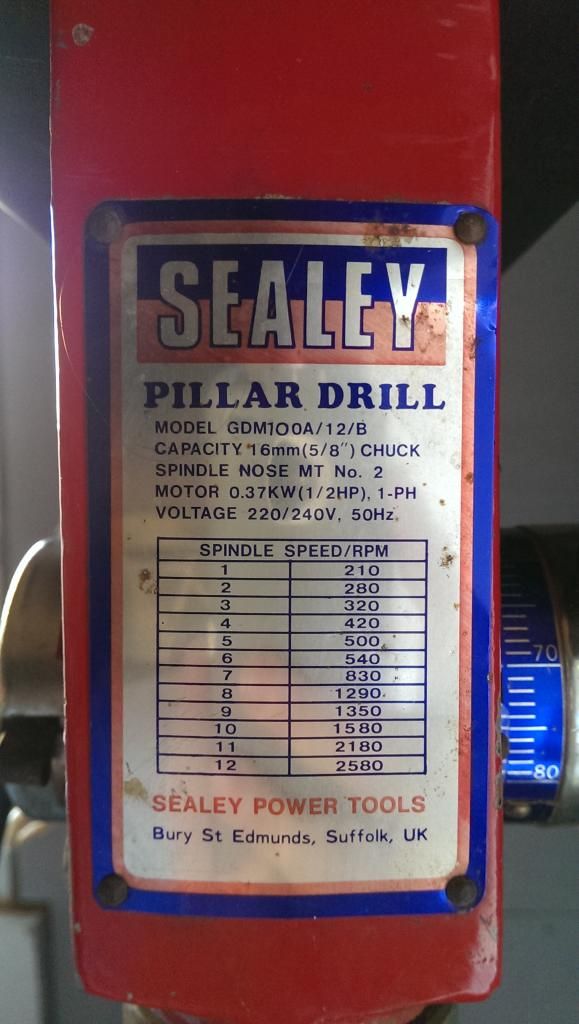

After giving it a clean it now looks more like this-

Just waiting for the chuck key to come now. Very pleased and for only 25 quid and a 70 mile round trip.

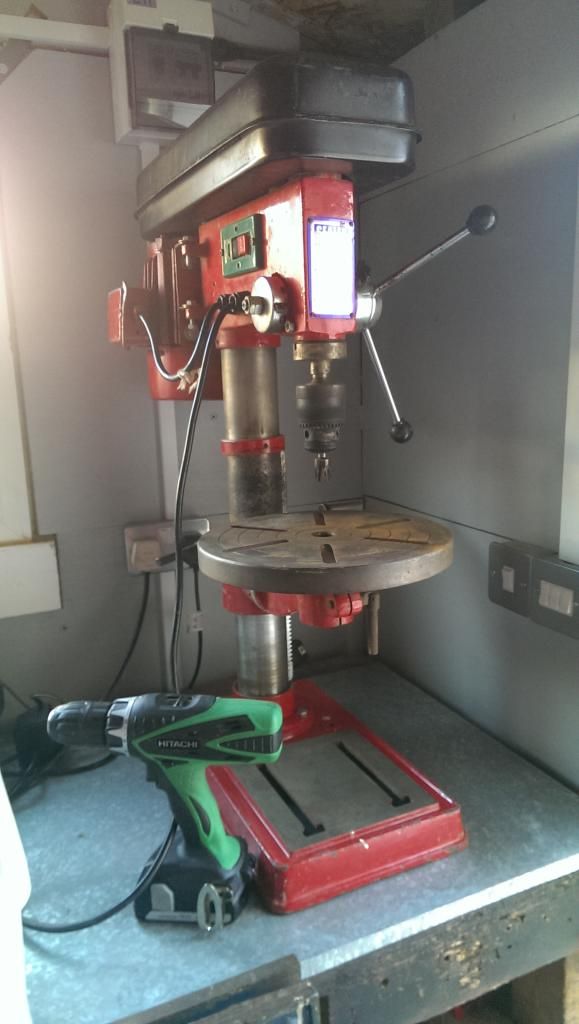

How ever I stumbled across this-

Merely described as pillar drill, no longer required. With a typo of pilar in the title, me being the avid ebayer I always search a couple of a typos too.

So went to pick it up, fella kindly swept off the kilo of saw dust it was under. Personally I clean up an item before even listing but thats why my items sell better.

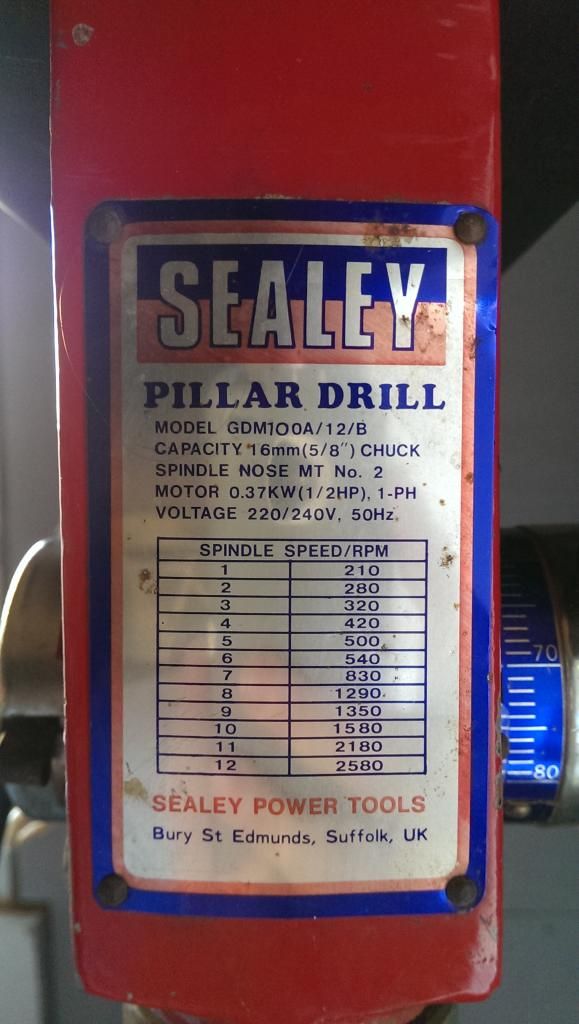

After giving it a clean it now looks more like this-

Just waiting for the chuck key to come now. Very pleased and for only 25 quid and a 70 mile round trip.