El Barto

👍

Thanks Tyreman. I did it before seeing your post but I don't think I was far off. Diagonal strokes certainly helped. It took absolutely f-ing ages to get it flat and square but finally it's ready to be smoothed. I don't want to ham it up too much but it's lucky I had the past couple of days off work because this would have been a ballache to do over a few evenings, definitely glad I got it done in one lump. Also Tyreman, I wish it was as simple as only taking off the high spots!!!!! Mine was quite staggered in the end. Lesson learnt for next time.  #-o

#-o

I ended up having to rig together a way to stop the bench from moving around while I worked on it. While it's true that the bench is very heavy and stout, my floor is quite uneven and with the colossal amount of planing I had to do it jumped about. This isn't something I'm worried about as I think it's unlikely I'll be doing this kind of heavier duty work in the future, not to mention the bench will eventually be against a wall.

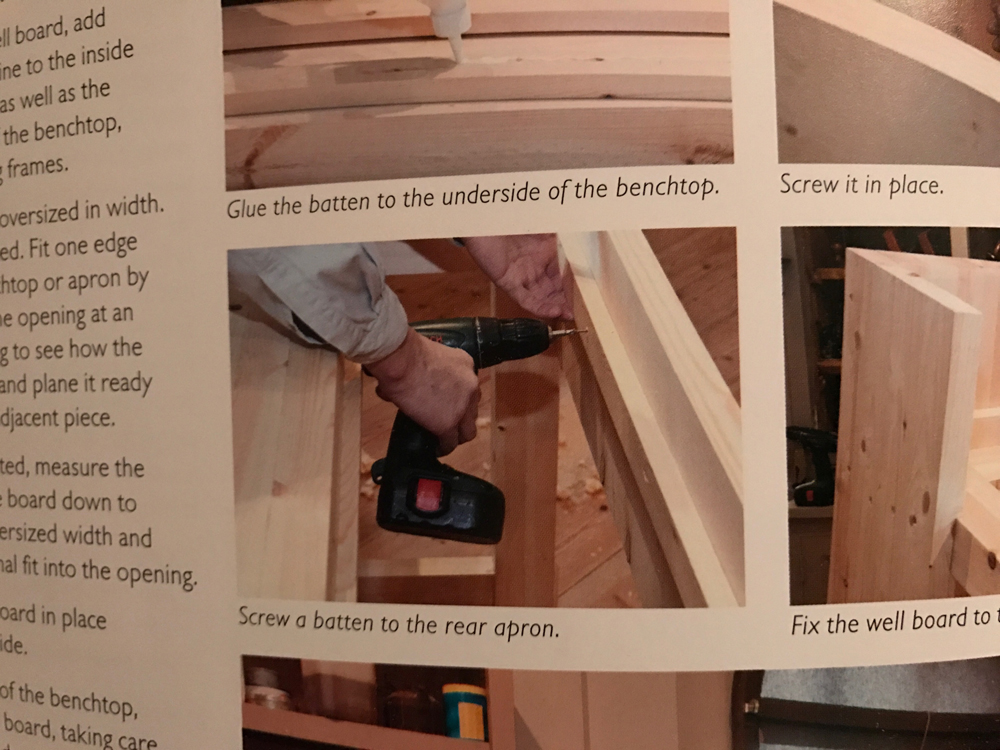

All in all a productive but tiring day, albeit a necessary one. Next up is fixing the well board in place permanently, planing the ends of the top flush and smoothing it out.

(homer)

I ended up having to rig together a way to stop the bench from moving around while I worked on it. While it's true that the bench is very heavy and stout, my floor is quite uneven and with the colossal amount of planing I had to do it jumped about. This isn't something I'm worried about as I think it's unlikely I'll be doing this kind of heavier duty work in the future, not to mention the bench will eventually be against a wall.

All in all a productive but tiring day, albeit a necessary one. Next up is fixing the well board in place permanently, planing the ends of the top flush and smoothing it out.

(homer)