El Barto

👍

Ok I lied there is no twist, I just wanted to get your attention. There is a workbench though, or at least the beginnings of one. And instead of spamming the "... workshop" thread I decided to start a wip. If you would like to scroll to the end you can check out thetyreman's thread; my bench will be very similar to his though probably not quite as good.

Having cut the mortises for the legs a couple of days ago I spent today cutting the tenons and assembling the H frames. With the mortises out of the way I thought the rest would be a breeze, how naive. Turns out cutting tenons is difficult, especially of this size where it's so easy to make a mistake, of which I made several. But by the end of it I could feel a definite improvement and had a much more solid technique, errors were minimal.

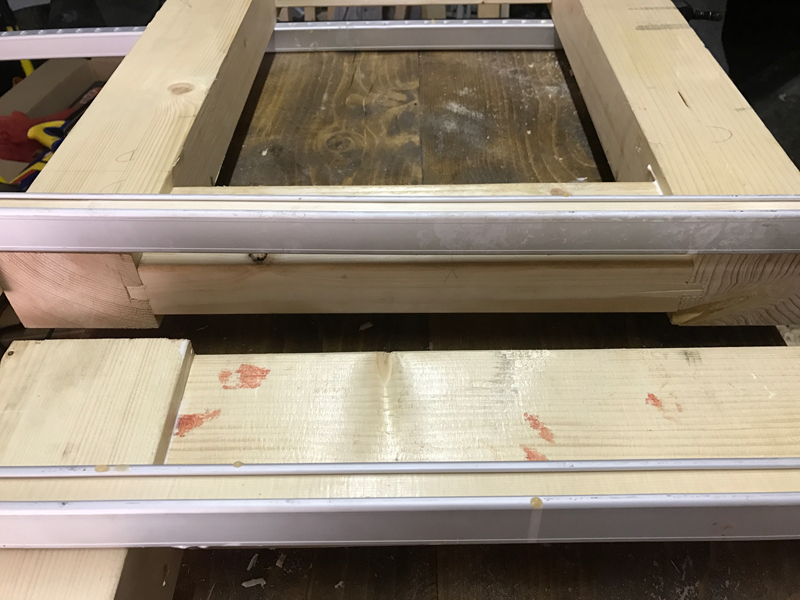

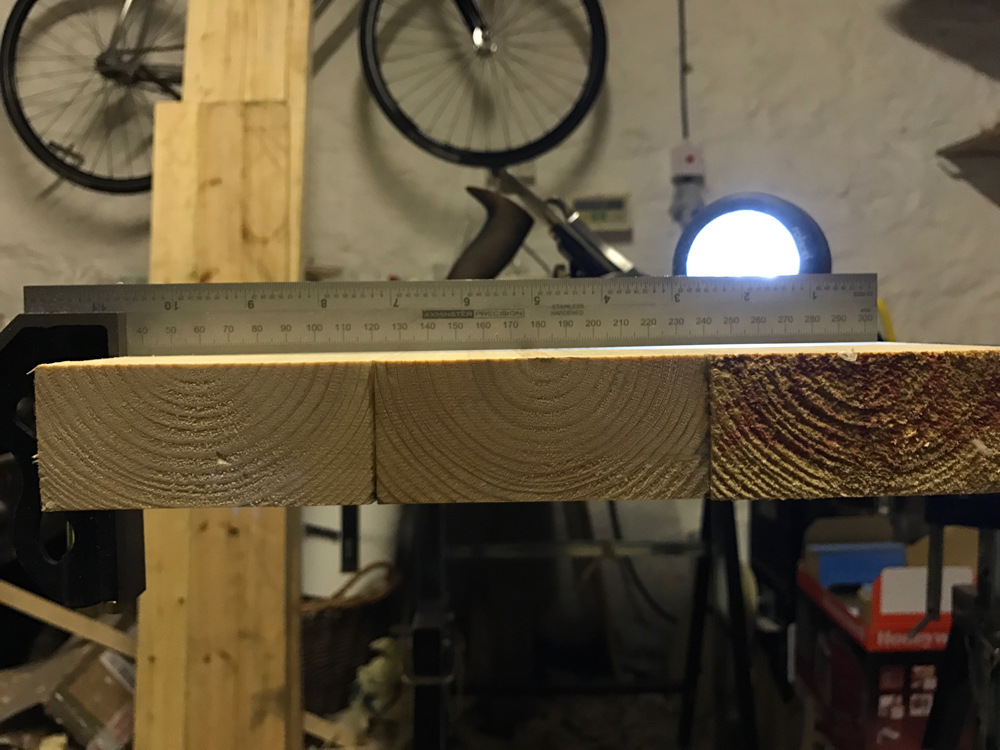

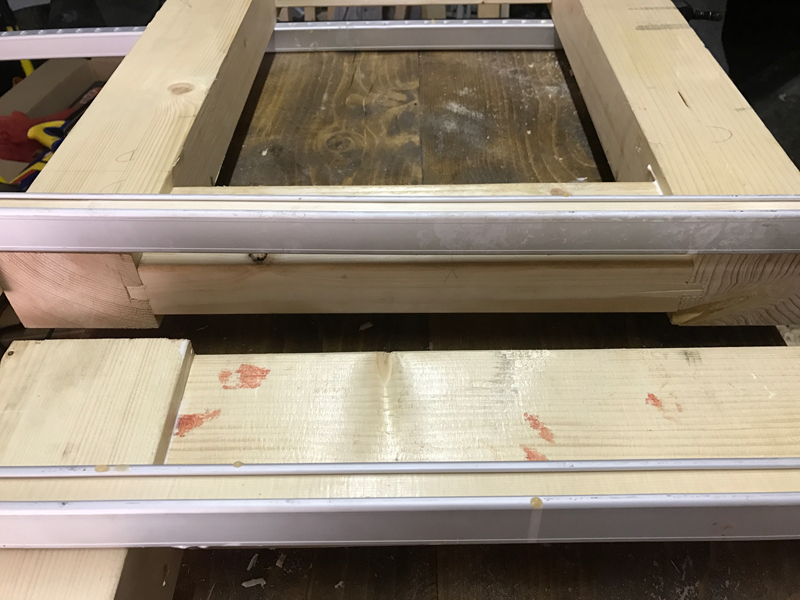

Below are photos of the glued legs clamped up. As thetyreman mentioned, the gaps really do close up a surprising amount when everything is clamped. One of the legs is bang on 22", the other is a couple of mm under which I hope won't matter much (though please chime in if it will). As you can see in the photos there is also a fair amount of blood. This was a nightmare. I'm on blood thinners - even with the slightest nick (in this case caught my finger on a saw) I will bleed for hours. And I cut myself fairly often ffs.

Speaking of glue, I used Gorilla Glue. HUGE mistake. With their superior duct tape I thought the glue would also be good, but it's horrible stuff. Foams up and gets everywhere (although I can't speak for its holding quality). Got some proper glue on order from Toolstation for the rest of the bench.

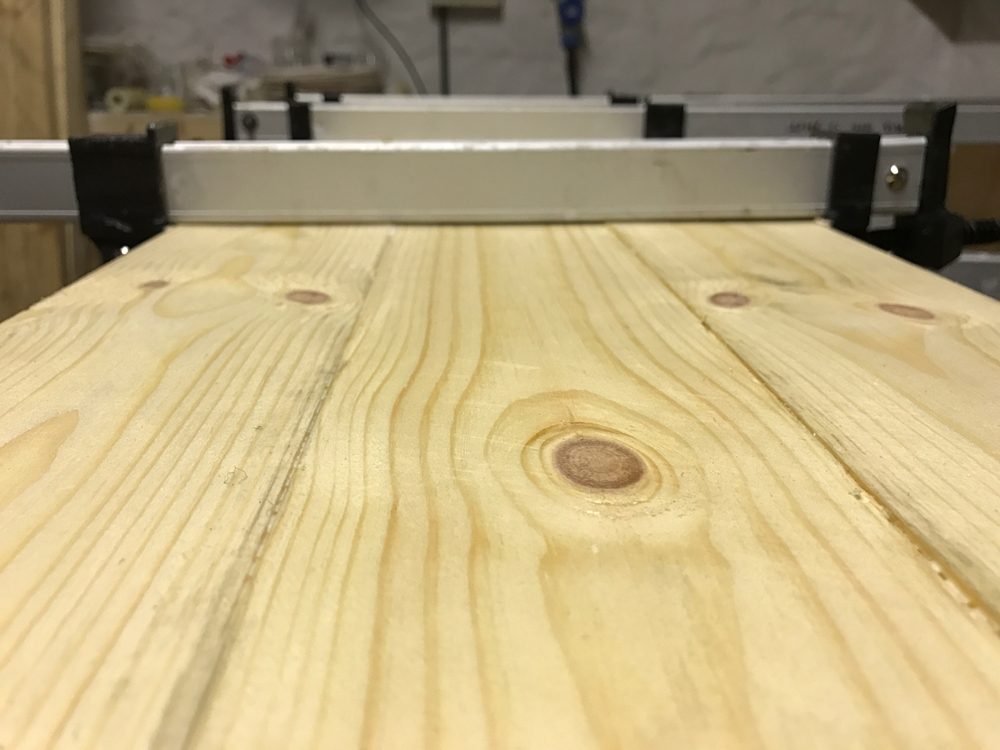

That seems like a good place to leave the build for Christmas, I'm pretty happy with the progress so far. One thing I'm not happy with is the benchtop I made out of rough sawn. It has planed edges on the top and rounded on the bottom, not really a big deal but I know it'll bug me if I don't fix it. By fix it I mean buy PAR and have done with it, although I'm slightly loathe to take the easy way out. But more than that I want to finish this thing and start using it, and also not have too many things that I don't like or compromised over.

Thanks for reading.

Having cut the mortises for the legs a couple of days ago I spent today cutting the tenons and assembling the H frames. With the mortises out of the way I thought the rest would be a breeze, how naive. Turns out cutting tenons is difficult, especially of this size where it's so easy to make a mistake, of which I made several. But by the end of it I could feel a definite improvement and had a much more solid technique, errors were minimal.

Below are photos of the glued legs clamped up. As thetyreman mentioned, the gaps really do close up a surprising amount when everything is clamped. One of the legs is bang on 22", the other is a couple of mm under which I hope won't matter much (though please chime in if it will). As you can see in the photos there is also a fair amount of blood. This was a nightmare. I'm on blood thinners - even with the slightest nick (in this case caught my finger on a saw) I will bleed for hours. And I cut myself fairly often ffs.

Speaking of glue, I used Gorilla Glue. HUGE mistake. With their superior duct tape I thought the glue would also be good, but it's horrible stuff. Foams up and gets everywhere (although I can't speak for its holding quality). Got some proper glue on order from Toolstation for the rest of the bench.

That seems like a good place to leave the build for Christmas, I'm pretty happy with the progress so far. One thing I'm not happy with is the benchtop I made out of rough sawn. It has planed edges on the top and rounded on the bottom, not really a big deal but I know it'll bug me if I don't fix it. By fix it I mean buy PAR and have done with it, although I'm slightly loathe to take the easy way out. But more than that I want to finish this thing and start using it, and also not have too many things that I don't like or compromised over.

Thanks for reading.