devonwoody

Established Member

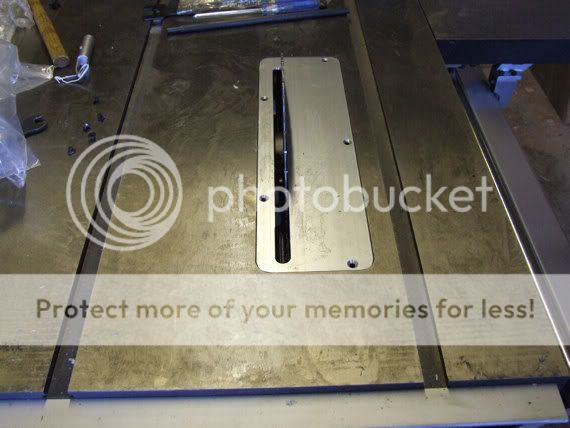

I had an Axminster tablesaw delivered yesterday AW10bsb2 and the saw blade when wound up practically touches the table gullet.

I have had a Record, gone back.

I have had a Schappach, gone back.

I have had an Axminster who said they would take it back but they are going to give me an engineer call first in the hope that the holding blade mechanism can be put in the correct position(factory set)

I have still got to wait a week tho for an engineer to call.

I cannot even use my Triton (which I have had 5 years) because there is not enough space in the workshop to have both in a working position.

I have had a Record, gone back.

I have had a Schappach, gone back.

I have had an Axminster who said they would take it back but they are going to give me an engineer call first in the hope that the holding blade mechanism can be put in the correct position(factory set)

I have still got to wait a week tho for an engineer to call.

I cannot even use my Triton (which I have had 5 years) because there is not enough space in the workshop to have both in a working position.