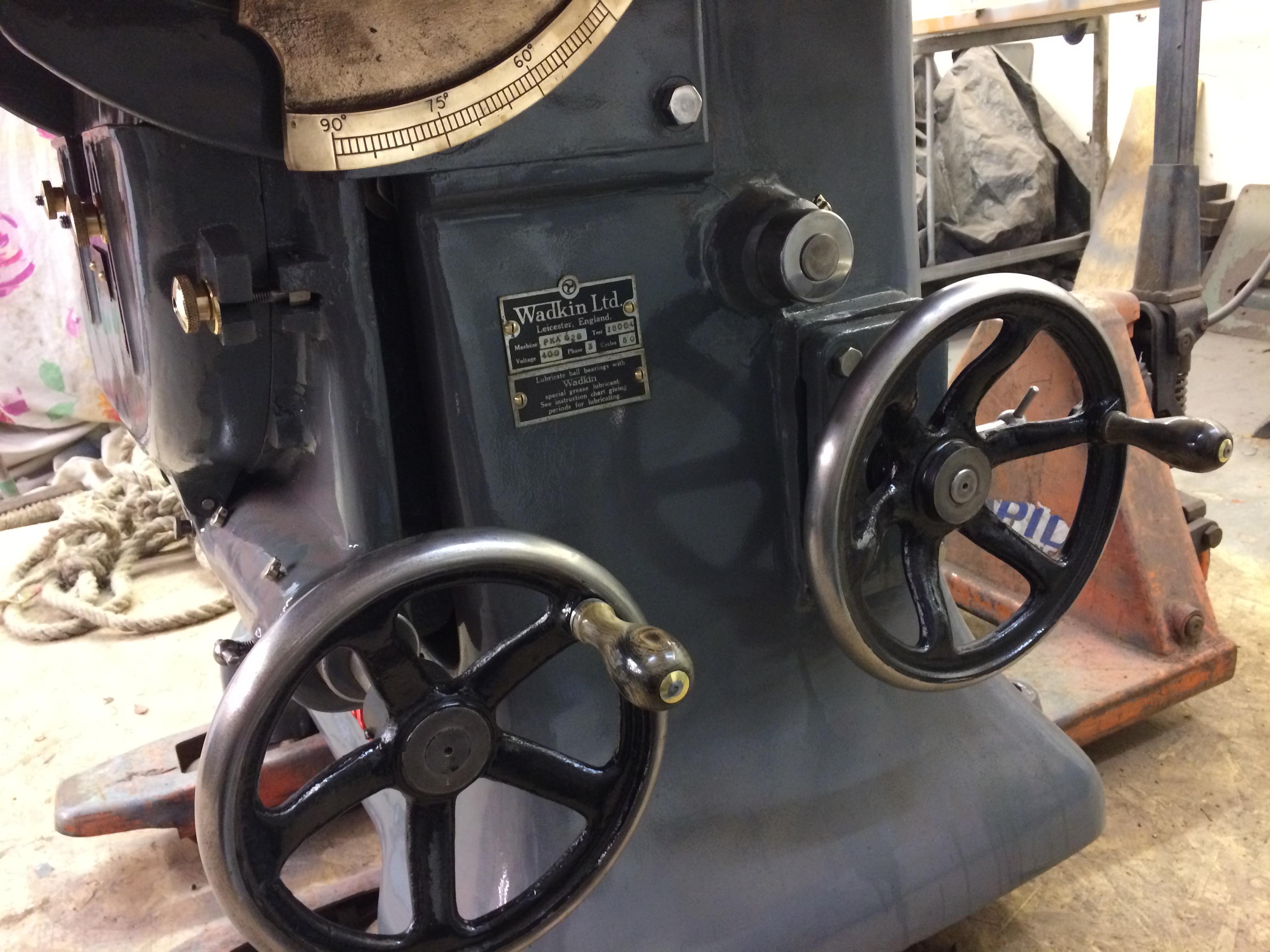

AJB Temple

Finely figured

That crown guard is ridiculously nice.

wallace":1z74cxz5 said:It cost £5OO in its original condition :shock:

TFrench":1cgl9vs9 said:Stunning work as always mate! Were all the crown guards brass or was it just early ones?

Enter your email address to join: