wallace

Established Member

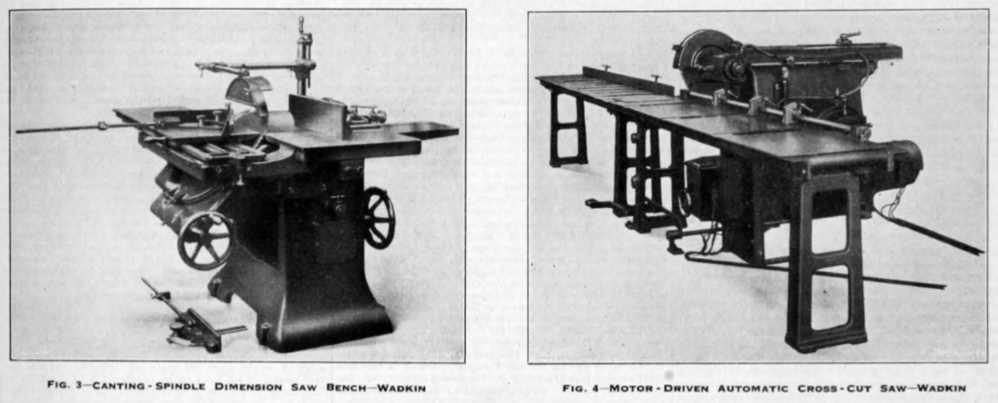

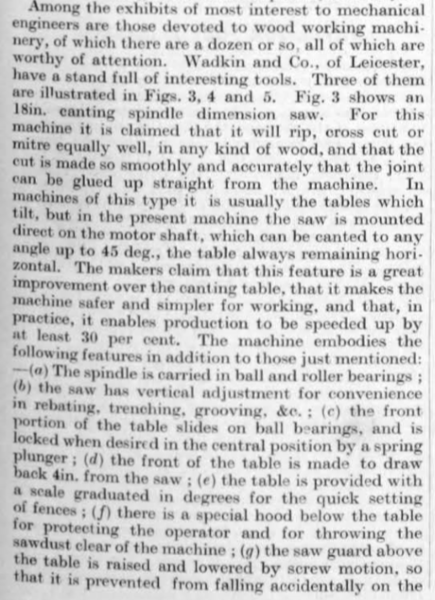

Since I finished the bandsaw yesterday I thought I'd crack on and start this thing. I got a message a couple of years ago asking if I knew of any history to it. All I knew was that it was an early generation 1 machine. Oh and I wants it.

I offered to buy it but he was not ready to sell it. But he did say if and when he would contact me. Going forward I messaged him every few months to see if it was for sale and eventually he must of got sick of me asking so he offered it. The price was high, twice as much as I knew I could buy one for elsewhere. But like I said earlier 'I wants it'.

His place was not suitable for pallet collection so I drove to halifax and put it in my VW. I remember it well because after I'd loaded up and secured everything I had a little rest and had some food and coffee. It was then I saw a middle aged woman saunter up to my window and ask, 'do ye fancy any business luv' in a very yorkshire accent. I declined but did offer her a butty, she looked knackered.

Anyway I digress, I've been looking forward to this one for ages.

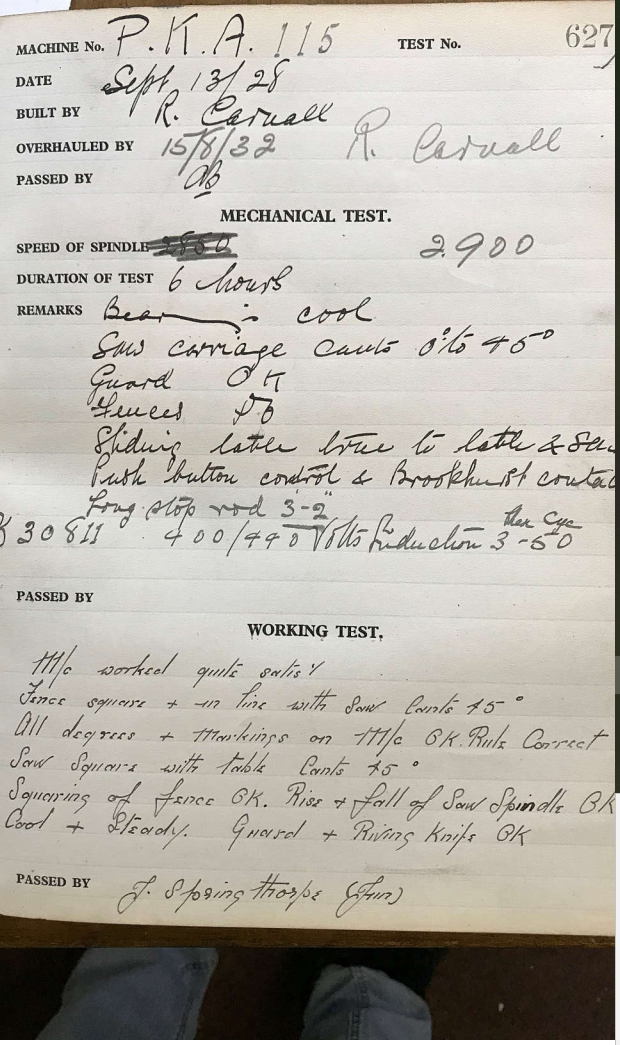

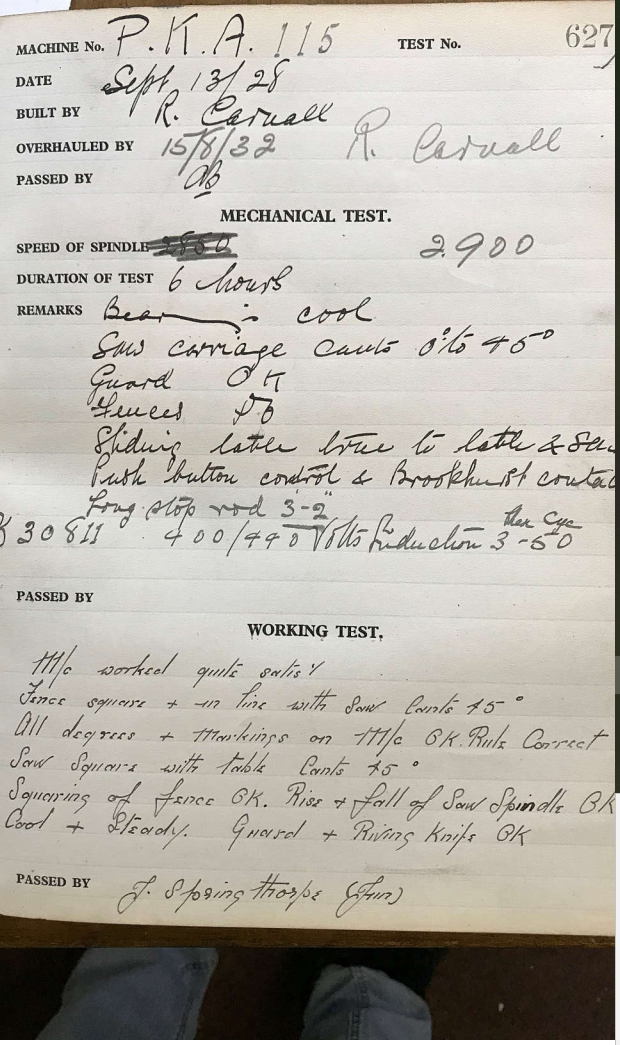

Do you see the 115 stamped after the PK, that is what number it is but wadkin started at 100 so my machine is the 6th machine built.

It was built on 13th sept 1928

It was overhauled 4 years later and it looks like the speed was changed. Can you imagine a machine nowadays being tested for 6hrs.

The thing that floats my boat is that the PK was unveiled to the public at the 1928 trade exhibition, maybe this is my machine.

This is the first time I've done a generation 1 and their are lots of modifications on later machines

The ruler is etched into the table, later a chesterman ruler was inset

These bolts are for extensions to acomodate a longer slider

Its had alot of work done to it at some point, it has a modern dc break and a crown guard from a much later PP

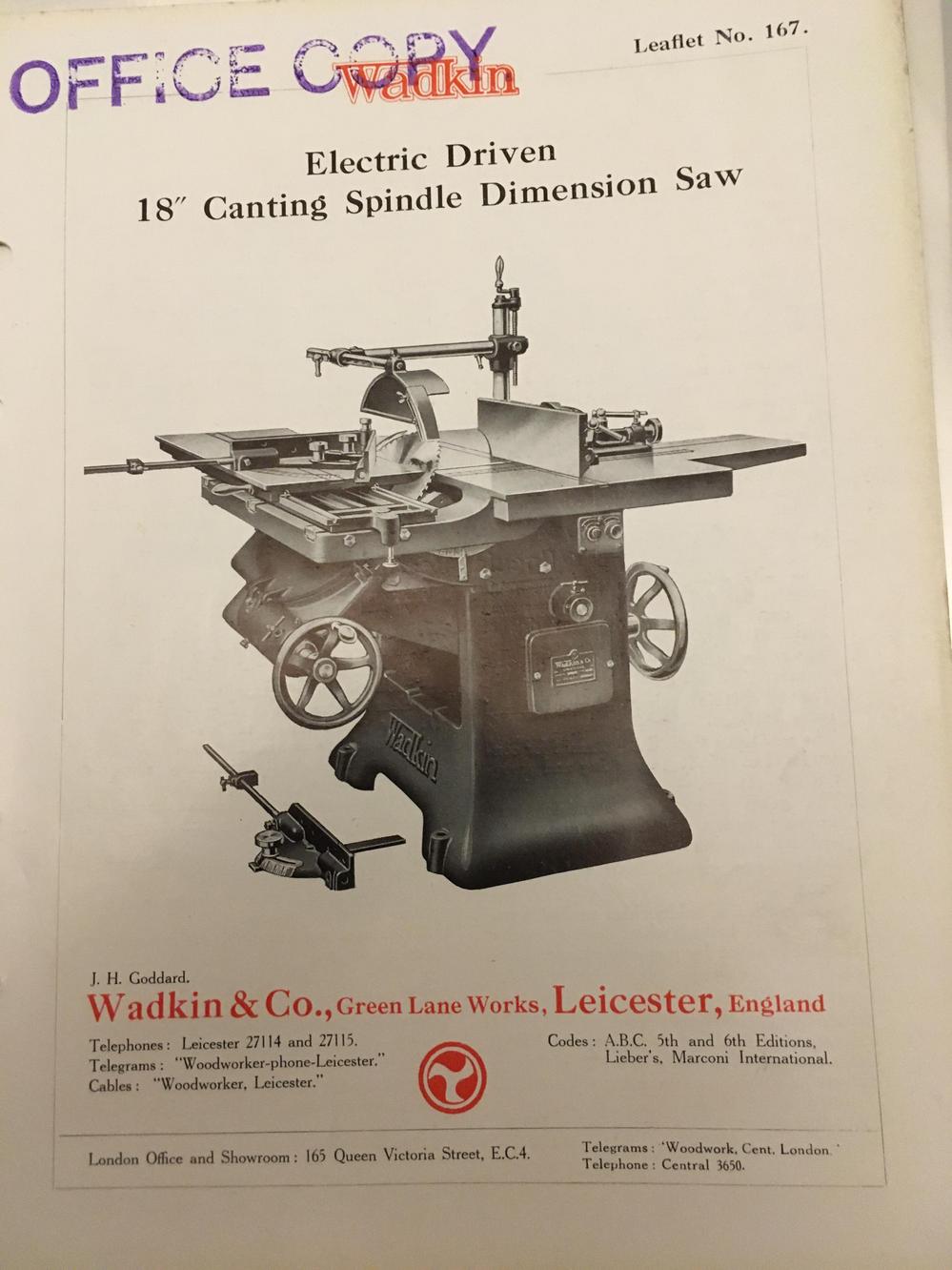

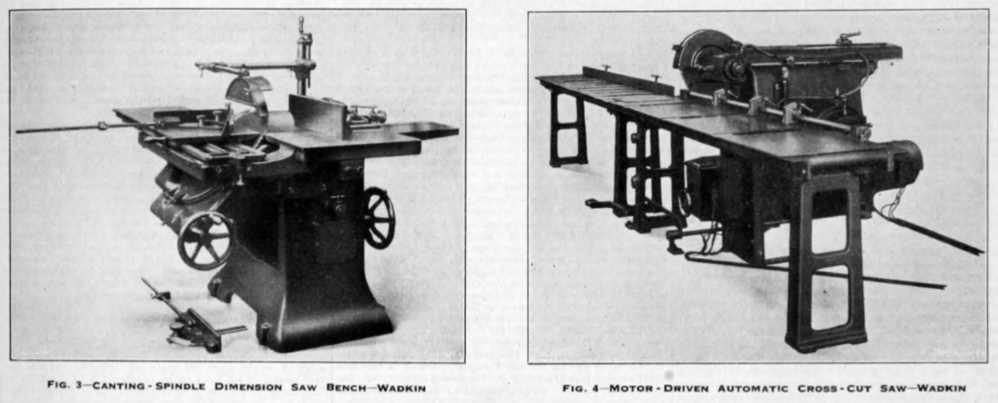

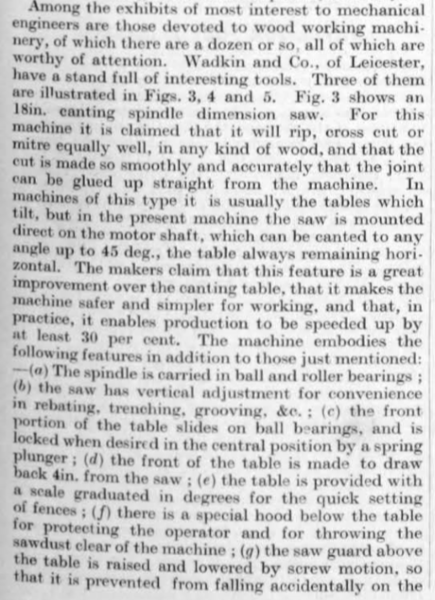

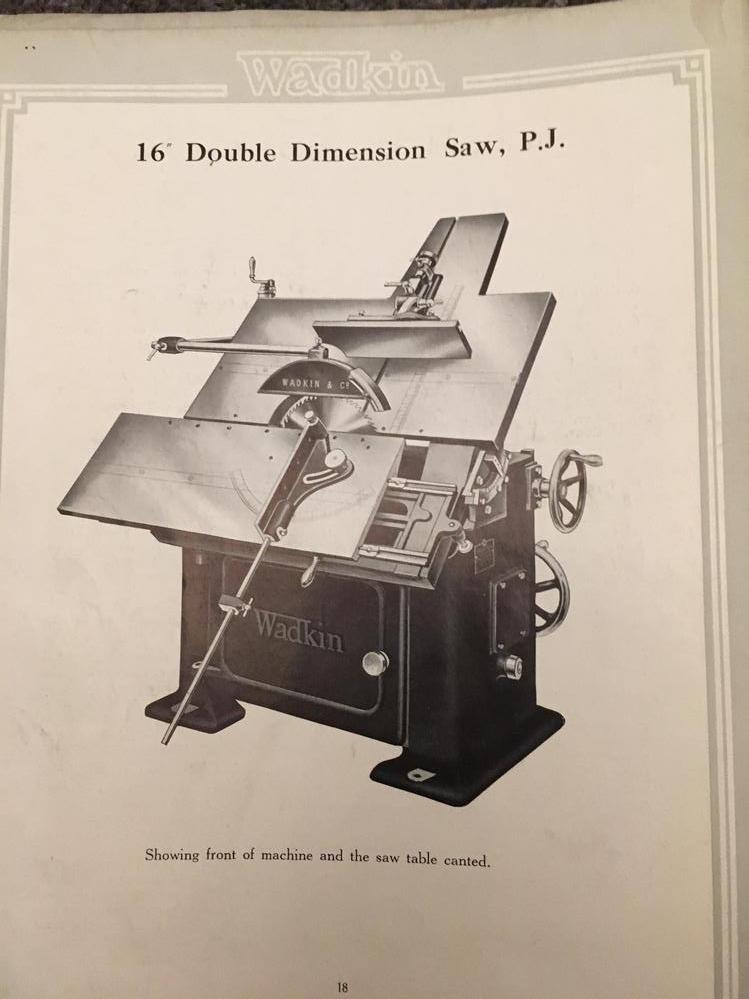

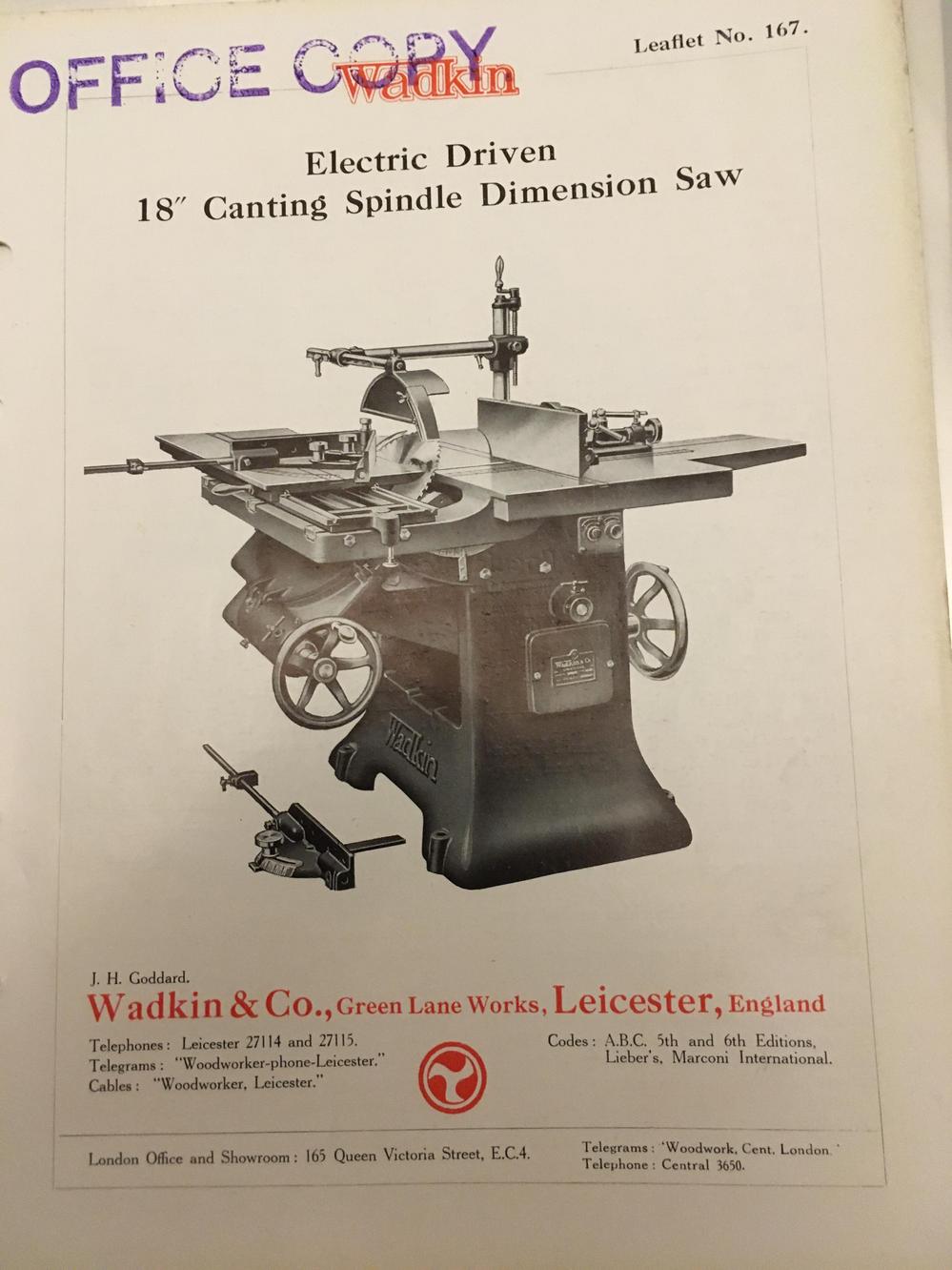

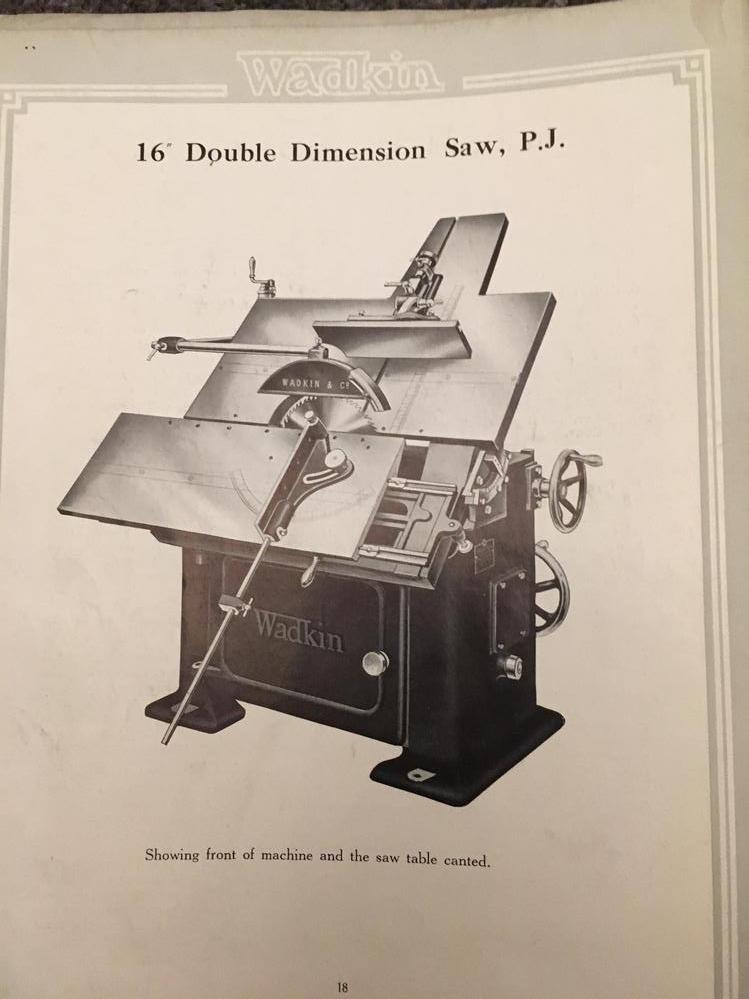

Back in the day this is what was in use

I cant imagine why the PK took off

I offered to buy it but he was not ready to sell it. But he did say if and when he would contact me. Going forward I messaged him every few months to see if it was for sale and eventually he must of got sick of me asking so he offered it. The price was high, twice as much as I knew I could buy one for elsewhere. But like I said earlier 'I wants it'.

His place was not suitable for pallet collection so I drove to halifax and put it in my VW. I remember it well because after I'd loaded up and secured everything I had a little rest and had some food and coffee. It was then I saw a middle aged woman saunter up to my window and ask, 'do ye fancy any business luv' in a very yorkshire accent. I declined but did offer her a butty, she looked knackered.

Anyway I digress, I've been looking forward to this one for ages.

Do you see the 115 stamped after the PK, that is what number it is but wadkin started at 100 so my machine is the 6th machine built.

It was built on 13th sept 1928

It was overhauled 4 years later and it looks like the speed was changed. Can you imagine a machine nowadays being tested for 6hrs.

The thing that floats my boat is that the PK was unveiled to the public at the 1928 trade exhibition, maybe this is my machine.

This is the first time I've done a generation 1 and their are lots of modifications on later machines

The ruler is etched into the table, later a chesterman ruler was inset

These bolts are for extensions to acomodate a longer slider

Its had alot of work done to it at some point, it has a modern dc break and a crown guard from a much later PP

Back in the day this is what was in use

I cant imagine why the PK took off