Again...many thanks for the comments guys...there are some old friends popping up here but some new ones too and I hope to meet you all some day.

Mick..the offer of coffee is still open to you as before if you are passing...we would love to say hi again.

Like most things with this plane, I have tried to get the best result from each component but at the end of the day...the bit that really matters to use this for its primary purpose...shaving wood... is the iron.

It was probably perfectly sharp enough to shave pretty well straight from Philly's hardening and surface grinding but obviously the grind marks on the face need to be taken out to give the one straight edge of two which make up the perfect edge.

Anyone considering buying one of Philly's replacement irons...or indeed, one of his excellent planes should look at the following images pretty closely...I think you will see why we all love his work!

Firstly...straight "out of the box"....

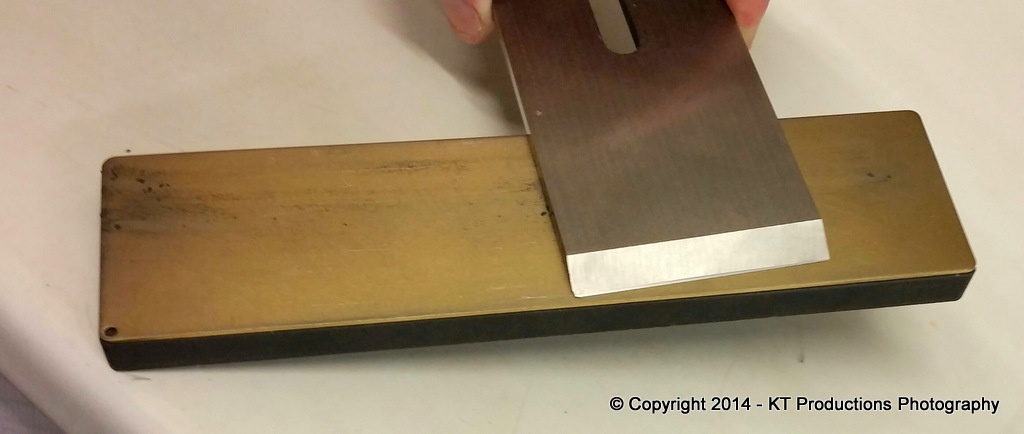

..wiped over the excellent Fallkniven coarse ceramic diamond stone...shows a very tiny dip at the end which is to be expected. When I say tiny we are talking microns here and the following pictures prove this.

I have often flattened irons on a whetstone with water and have had the iron "grab" the hone and stick to it so you can lift the stone....but NEVER on a dry diamond stone...

....and this is a very heavy stone so a good sign that things are as they should be.

After a few minutes most of the grind marks are gone and the following shots show how flat this face is....

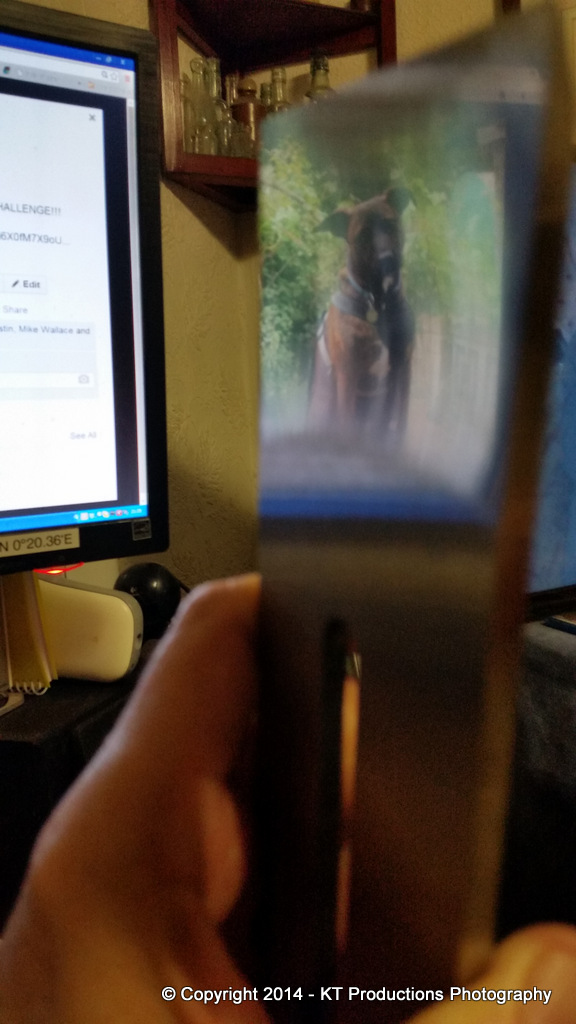

....and close up....

So I think we can only call this perfection and I am hardly surprised at this as it came from one of the master planemakers of our generation...

Phil Edwards and

Philly Planes!

I have to get to the edge and go a bit finer but the edge is already popping hairs on my arm which is now bald...so I'll leave with a huge vote of thanks to you Phil...you are the man!!

=D> =D> =D> =D> =D>

Jimi