Shultzy

Established Member

I, and many others, on the forum managed to visit Corby to purchase these science tables. I bought two of these frames and four tops...

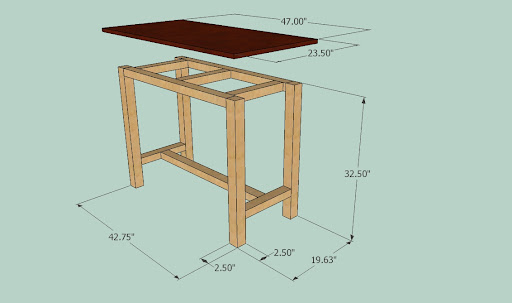

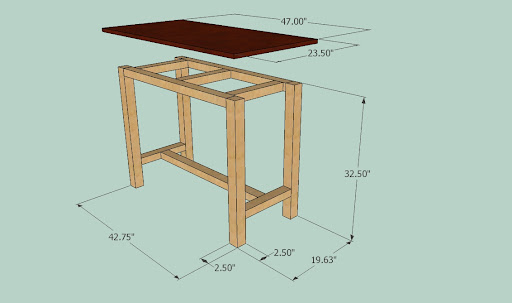

...and I'm going to convert it to this.

This is how they arrived, before cleaning, and after cutting the grooves...

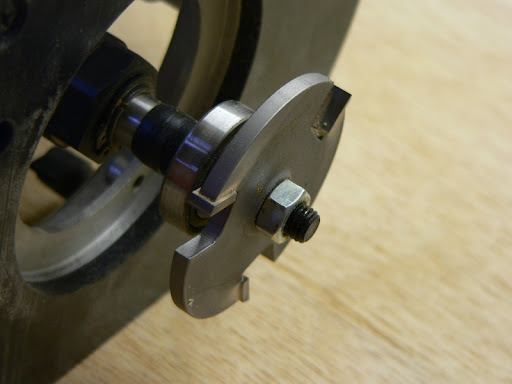

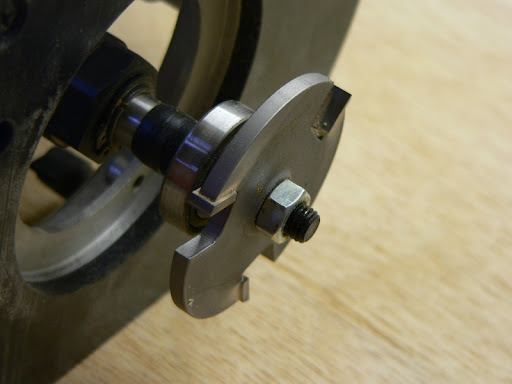

...with this monster. A bit scary to use "hand-held" but I cut the groove in three passes.

I cleaned up the original, made the end panels and the top and bottom rails.

I glued the panels and the top rails. The bottom rails are from another bench and were pocked-holed and glued as they weren't long enough to put a tenon on. I made the feet to raise the original bench. I bored 25mm holes at each end of the long foot, clamped these to the legs and used the hole as a guide to drill into the legs. Same with the short feet. I then turned four 25mm dia dowels and glued all together.

This is my 30 year old scraper which I used to clean off the varnish on the tops which I'm about to cut.

The drawers are 37 3/4" wide and I will use full extension slides and fronts similar to my other drawers shown in the fifth picture. I have lots of offcuts of 1/2" ply and mdf, so to get rid of these off-cuts what combination should I make the drawers out of :-

only the ply

only the mdf

ply base mdf sides

mdf base ply sides

I think it might be prudent to put a strengthening strip under the centre of each drawer base.

...and I'm going to convert it to this.

This is how they arrived, before cleaning, and after cutting the grooves...

...with this monster. A bit scary to use "hand-held" but I cut the groove in three passes.

I cleaned up the original, made the end panels and the top and bottom rails.

I glued the panels and the top rails. The bottom rails are from another bench and were pocked-holed and glued as they weren't long enough to put a tenon on. I made the feet to raise the original bench. I bored 25mm holes at each end of the long foot, clamped these to the legs and used the hole as a guide to drill into the legs. Same with the short feet. I then turned four 25mm dia dowels and glued all together.

This is my 30 year old scraper which I used to clean off the varnish on the tops which I'm about to cut.

The drawers are 37 3/4" wide and I will use full extension slides and fronts similar to my other drawers shown in the fifth picture. I have lots of offcuts of 1/2" ply and mdf, so to get rid of these off-cuts what combination should I make the drawers out of :-

only the ply

only the mdf

ply base mdf sides

mdf base ply sides

I think it might be prudent to put a strengthening strip under the centre of each drawer base.