I have a Dewalt 708 SCMS. I am fed up with getting dust everywhere. I have tried the original factory fitted extract, I have tried the upgraded version. I have tried the roofing membrane trick and I have tried an adjustable dust nozzle adjacent to the saw. I even built a dust hood at one time. Does anyone know how to stop the dust getting everwhere with this otherwise good saw? Alternatively does the dust extraction on the alternatives work effectively?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SCMS Dust Extraction

- Thread starter PAC1

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

gidon

Established Member

The dust extraction in my Bosch is not much good either - dust does come out of the extraction hole so you need something collecting it but a lot also comes out around the saw.

I'm guessing the Festool Kapex saws do a good job - but apart from that it seems to be a common problem with SCMSs.

I have a vague recollection of Olly making a dust shroud for his saw but can't remember details or whether it was effective or not.

Cheers

Gidon

I'm guessing the Festool Kapex saws do a good job - but apart from that it seems to be a common problem with SCMSs.

I have a vague recollection of Olly making a dust shroud for his saw but can't remember details or whether it was effective or not.

Cheers

Gidon

OPJ

Established Member

gidon":2lpgx8or said:I have a vague recollection of Olly making a dust shroud for his saw but can't remember details or whether it was effective or not.

That idea (which was actually another of Steve Maskery's) is probably identical to the 'roofing membrane trick' mentioned in the original post. I've found it has helped much of the dust directed toward the rear of the machine to find its way in to the dust bag or vacuum hose. But still, as already mentioned, a lot of dust spews out from around the saw blade which I cannot seem to contain.

I can't think of a solution for this that won't potentially foul the timber you are trying to cut. Perhaps use decent respiratory protection and fit an air filter close by?

Max Power

Established Member

I have the large makita (ls1214) and even with a festool cleantec connected to it extraction is virtually non existent.  The kapex I saw demonstrated recently was excellent. Why is festool the only company that seem to place any importance on dust extraction ?

The kapex I saw demonstrated recently was excellent. Why is festool the only company that seem to place any importance on dust extraction ?

Doug B

Shy Tot

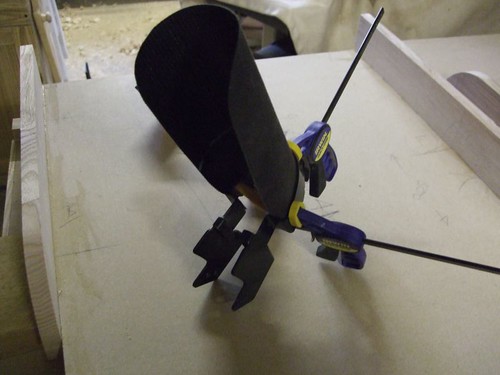

I made this for round my SCMS

It was made in sections joined by pegs, so it was easy to disassemble. the extraction went through the top.

It didn`t stop all the dust, but the vast majority of it, when i swapped the SCMS (just sold) for a RAS i went to the trouble of re-designing it for the new saw, as i`d been so happy with it.

It was made in sections joined by pegs, so it was easy to disassemble. the extraction went through the top.

It didn`t stop all the dust, but the vast majority of it, when i swapped the SCMS (just sold) for a RAS i went to the trouble of re-designing it for the new saw, as i`d been so happy with it.

Miles

The trick with the roofing membrane is to fix a small square of it around the dust extraction port or on the back of the saw guard in a U shape the idea being to catch the dust before it flies everywhere. Unfortunately on my Dewalt the amount it stops is minimal. I understand on some saws it makes a significant difference. Roofing membrane is used because it is strong and flexible. There is a post from Steve Maskery about it on the forum.

Trousers, for 960 quid I would want it to sweep up any dust that escaped the extraction system. I must admit having looked at the video on YouTube it is a very clever bit of kit. Do Festool do discount! Anyone want to buy a second hand Dewalt 708!!!!!!!

The trick with the roofing membrane is to fix a small square of it around the dust extraction port or on the back of the saw guard in a U shape the idea being to catch the dust before it flies everywhere. Unfortunately on my Dewalt the amount it stops is minimal. I understand on some saws it makes a significant difference. Roofing membrane is used because it is strong and flexible. There is a post from Steve Maskery about it on the forum.

Trousers, for 960 quid I would want it to sweep up any dust that escaped the extraction system. I must admit having looked at the video on YouTube it is a very clever bit of kit. Do Festool do discount! Anyone want to buy a second hand Dewalt 708!!!!!!!

Max Power

Established Member

Trousers, if only it was cheaper I'm sure everyone would already have one, but at 960 quid its probably not at the top of everyones list of must haves. That said I am determined to make my workshop as dust free as possible and intend to upgrade to one sometime this year

I've had it a while so was a fair bit cheaper when I bought it.

I haven't been able to teach it to sweep the floor yet but you never know.

It also comes into it's own on site when connected to the Cleantex cos it leaves customers houses relatively dust free.

I tried all that dust hood stuff with my not so old Makita and, to allow it to mitre/bevel at full capacity inside the hood meant the hood was as big as half the shop. Tried piping it up to all sorts of extractors and it just didn't do it for me.

As I get older I'm wanting a faff free life more and more, so things like extractors that auto switch on with good hand tools is something I have got to like.

To be honest I probably could do without a SCMS in the shop cos my table saw is v. accurate (and has built in extraction obviously), but for site work it's a must. However it is so useful for a lot of cuts in the workshop when the table saw is set up for ripping or moulding (its a combo).

I haven't been able to teach it to sweep the floor yet but you never know.

It also comes into it's own on site when connected to the Cleantex cos it leaves customers houses relatively dust free.

I tried all that dust hood stuff with my not so old Makita and, to allow it to mitre/bevel at full capacity inside the hood meant the hood was as big as half the shop. Tried piping it up to all sorts of extractors and it just didn't do it for me.

As I get older I'm wanting a faff free life more and more, so things like extractors that auto switch on with good hand tools is something I have got to like.

To be honest I probably could do without a SCMS in the shop cos my table saw is v. accurate (and has built in extraction obviously), but for site work it's a must. However it is so useful for a lot of cuts in the workshop when the table saw is set up for ripping or moulding (its a combo).

mailee

Established Member

I think I will just continue using the broom for my DW718. I did like the look of the Kapex but the handle was too clumsy for my small hands....plus it was almost twice the price of the DW! :shock:

maltrout512

Established Member

PAC wrote

:lol: :lol: :lol: :lol: Pigs may be able to fly before you will get discount.

:shock: :shock:Do Festool do discount!

:lol: :lol: :lol: :lol: Pigs may be able to fly before you will get discount.

OPJ

Established Member

OPJ

Established Member

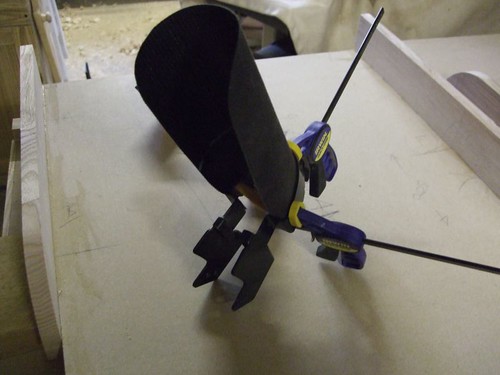

Hi, Tom. This is the only photo' I can find though, there really isn't much you need to know:

It was in one of Steve's articles from BW some time last year. The black plastic U-shaped-thing came from the bottom of the extraction port, behind the blade (I think it just un-clips, not screws or anything). I then took Steve's advise and glued the membrane on (smooth face on the inside) with a spray adhesive. Notice how the corners are rounded to prevent it snagging on the timber and fence.

Steve was kind enough to send me this small piece though, I don't know whether he'll have any left now. :wink:

By the way, if you think the SCMS is bad for spewing dust everywhere, you should try working on a floor-standing chain mortiser!! :x :wink:

:wink:

It was in one of Steve's articles from BW some time last year. The black plastic U-shaped-thing came from the bottom of the extraction port, behind the blade (I think it just un-clips, not screws or anything). I then took Steve's advise and glued the membrane on (smooth face on the inside) with a spray adhesive. Notice how the corners are rounded to prevent it snagging on the timber and fence.

Steve was kind enough to send me this small piece though, I don't know whether he'll have any left now. :wink:

By the way, if you think the SCMS is bad for spewing dust everywhere, you should try working on a floor-standing chain mortiser!! :x

Steve Maskery

Established Member

Tom

Settle down with a good bottle and get out your old British Woodworking magazines. It's in there somewhere. I can't remember which one and I don't have them catalogued, but it's there.

Actaully it's dead easy. Just cut a piece of roofing membrane wide enough so that you can fix it round the dust entry port of your machine and 3 or 4" deep. Stci it in place and it acts as a dust shroud persuading more dust into the DX than would otherwise be the case. The material is very flexible, like paper, and very strong, so it doesn't fray or wear out very quickly.

It's not 100% but it's the best I've found.

Cheers

Steve

Settle down with a good bottle and get out your old British Woodworking magazines. It's in there somewhere. I can't remember which one and I don't have them catalogued, but it's there.

Actaully it's dead easy. Just cut a piece of roofing membrane wide enough so that you can fix it round the dust entry port of your machine and 3 or 4" deep. Stci it in place and it acts as a dust shroud persuading more dust into the DX than would otherwise be the case. The material is very flexible, like paper, and very strong, so it doesn't fray or wear out very quickly.

It's not 100% but it's the best I've found.

Cheers

Steve

Max Power

Established Member

Olly your right about floor standing morticers, I've got a wadkin and dust extraction is non existent. the waste produced is chips rather than dust however so is not such a problem.

OPJ

Established Member

wizer":ahgfpsgg said:I'm intending on plumbing my RSDE2 in and ducting this year.

Well, you've got a busy two-days ahead of you, then!... :roll:

Alan, I was actually referring to a chain mortiser (quite different to a hollow chisel machine), which literally throws dust up and everywhere and makes quite a racket. Not a tool for fine furniture making though! :wink:

wizer

Established Member

- Joined

- 3 Mar 2005

- Messages

- 15,589

- Reaction score

- 1

OPJ":eocx0li4 said:wizer":eocx0li4 said:I'm intending on plumbing my RSDE2 in and ducting this year.

Well, you've got a busy two-days ahead of you, then!... :roll:

This is me we're talking about. It'll take a month of posting questions on the forums. Three days to balls it up. Another few weeks of questions on the forum. At which point I'll decide to sell it and buy something else. The cycle will then start again, ad infinitum

Similar threads

- Replies

- 6

- Views

- 1K