shed9

establiSHED member

Not sure if this is the correct place to post, but as this is for my work bench and predominantly to work with hand tools, this seemed relevant. It's quite heavy in pics but I never hear people complain when they get put up so here goes.

My main bench is an odd one, a hybrid of extruded aluminium and MFT style top. It's a fair size and weighs a ton. The alloy use is an offshoot of a CNC self-build that went from horizontal to vertical, hence I had a left-over (and very expensive) base that was crying out for use.

The alloy has multiple channels which perfectly fit the Festool clamps so generally I have used this method to clamp wood to the side of the bench however this has not been the best approach most of the time and I really need a proper vice. Anyhow I've always liked the Moxon style vices but wanted to add my own touch and whilst I believe they are probably worth the money I couldn't justify that cost for something I can make myself, especially not when I wanted three vice's around the bench.

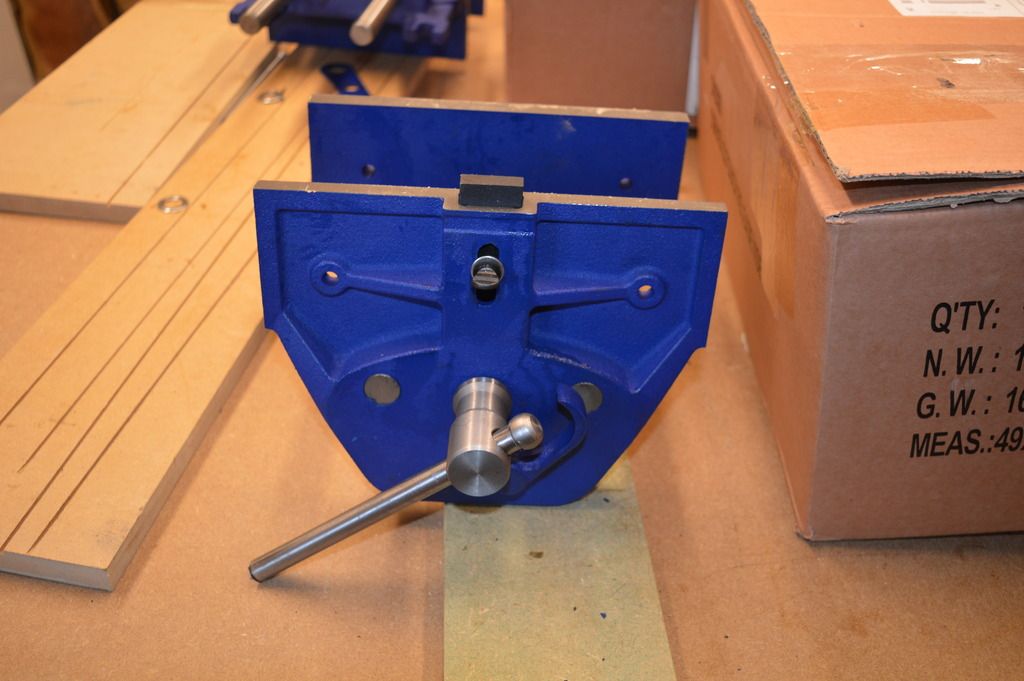

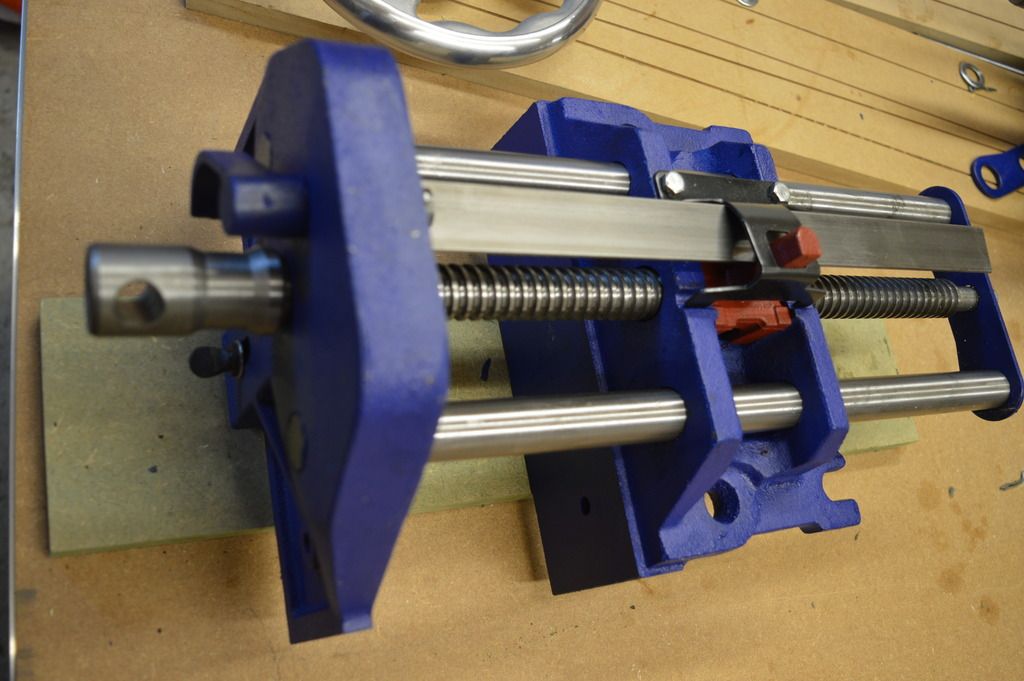

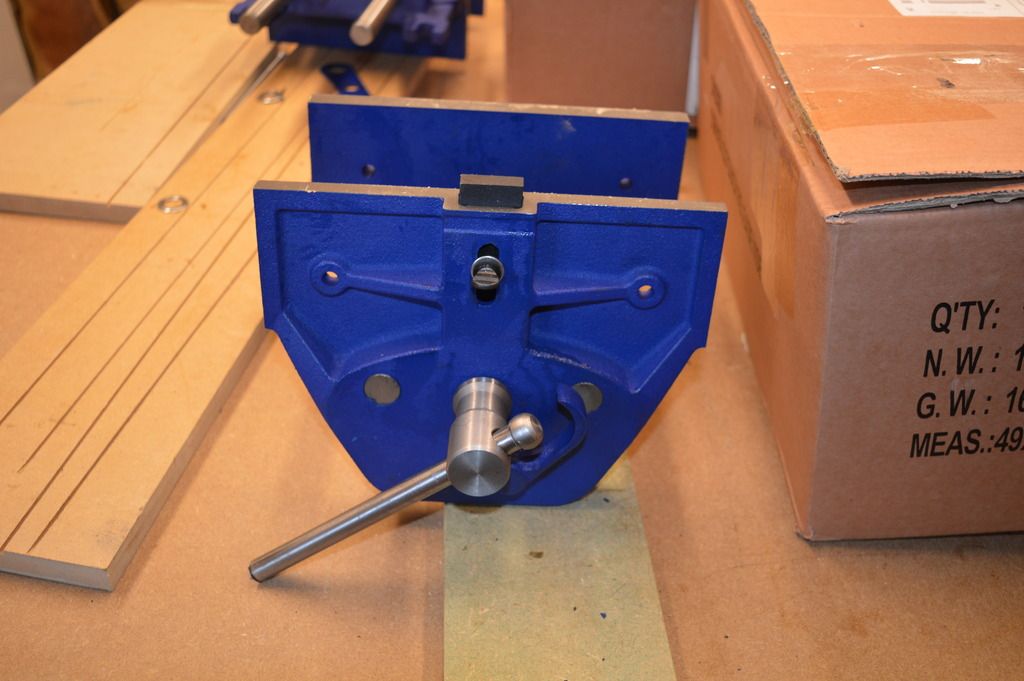

So I bought some Record 53 clones from Rutlands over the weekend with one of their 10% offers. These are effectively Record 53 derivative clones and copied by various suppliers from Axi to Eclipse, etc. They are not as tall (or heavy) as some of the usual suspects but given they will have wood backers this is kind of irrelevant to me. Also at £36 (with offer) a vice this is an absolute no-brainer for me and they are not too bad in quality.

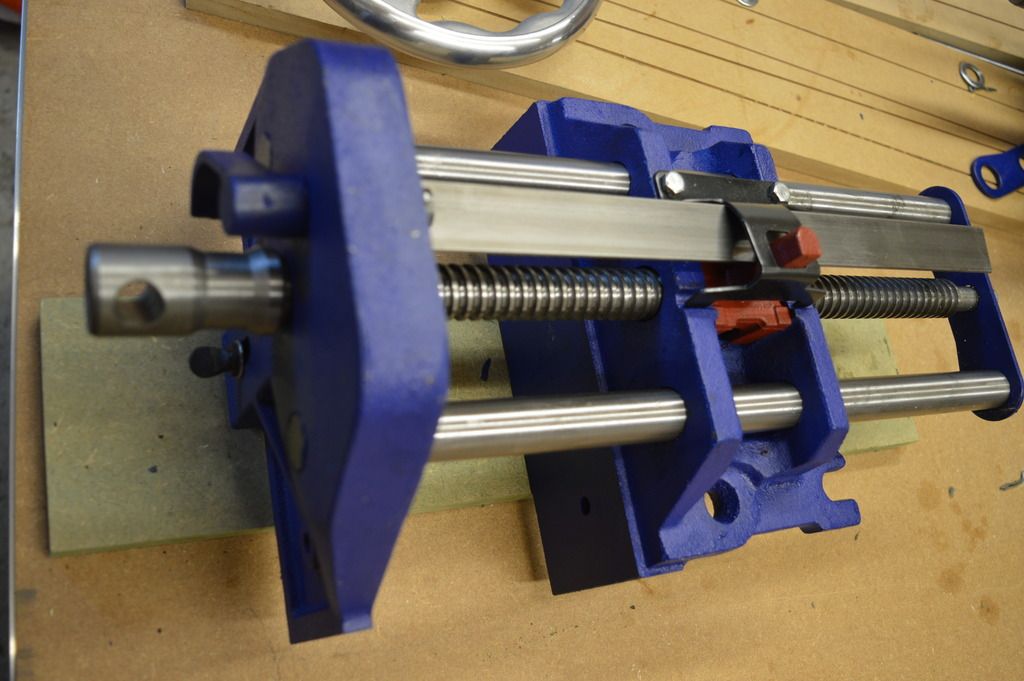

I then removed the screw;

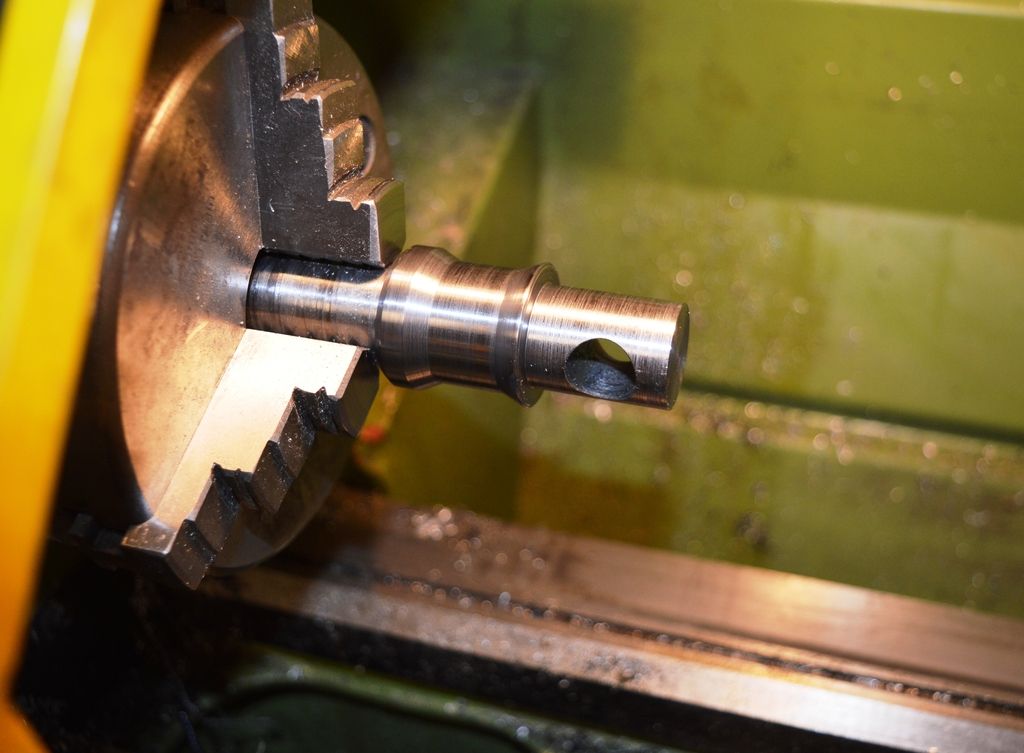

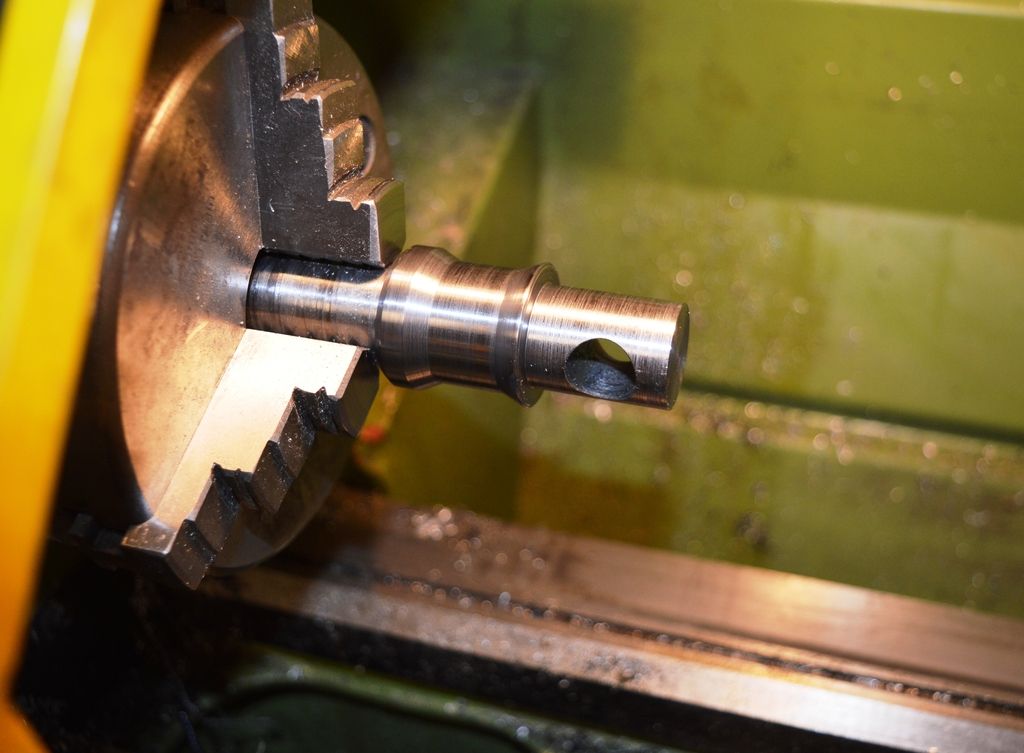

Set in the lathe and turned the end down to 22mm to this;

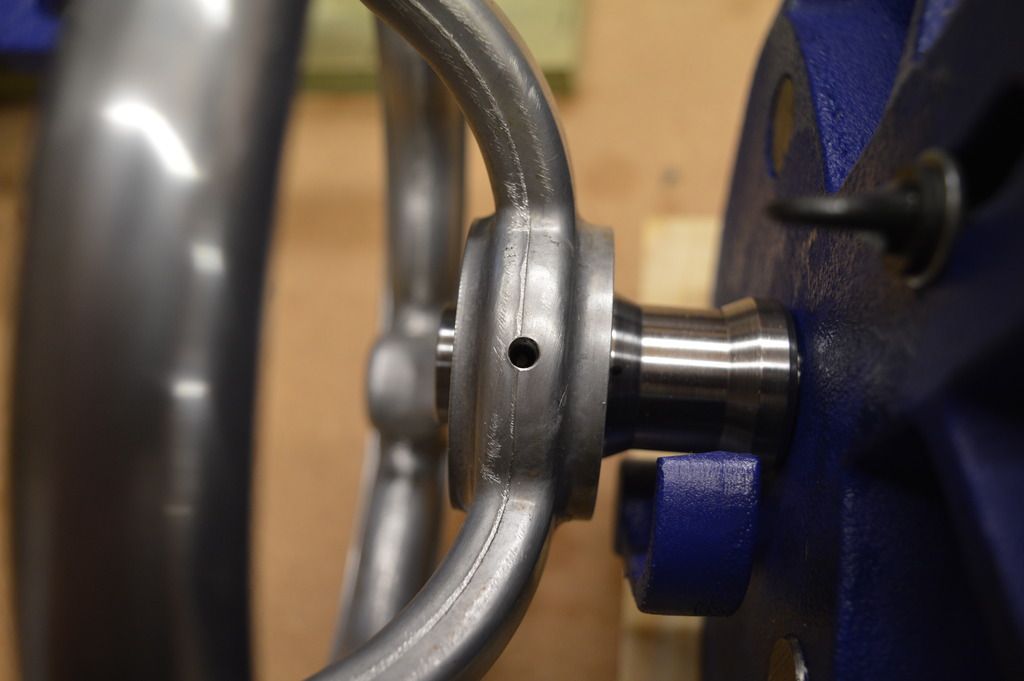

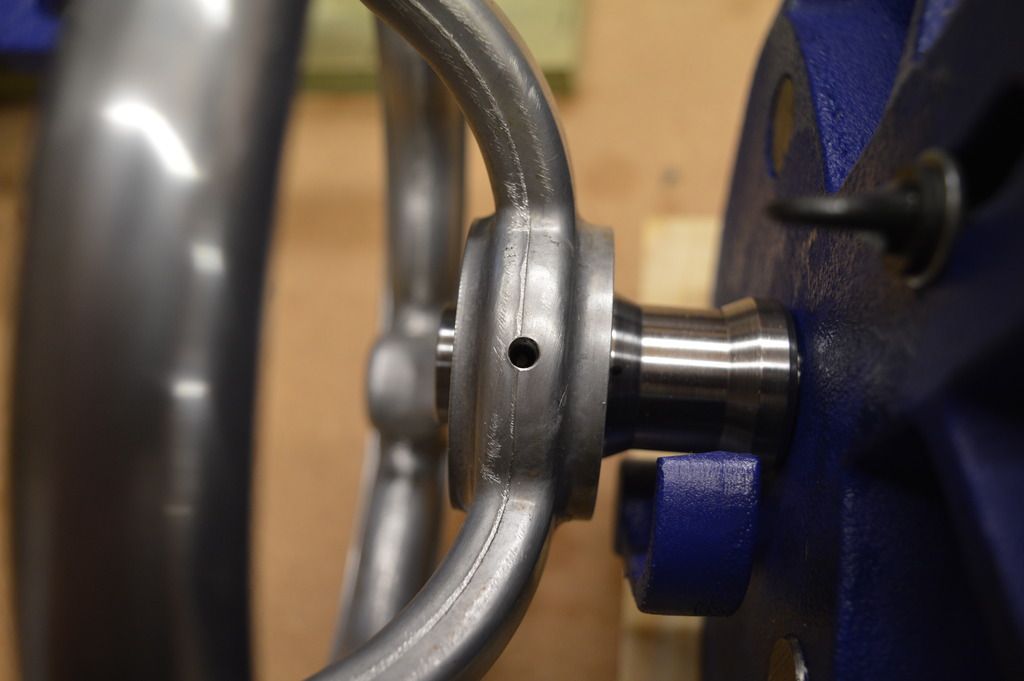

I then bought some 8" alloy cast hand wheels which were drilled out to 22mm;

Refitted to the vice with a tapped M5 grub screw;

And here is the finished vice;

Will post pics when fitted to the actual bench. The aim is to have two on one side and one on the end.

Anyone needing a vice or a replacement, although I haven't used them in anger yet I can't see how they can be churned out for >£40.

Any comments / advice appreciated.

My main bench is an odd one, a hybrid of extruded aluminium and MFT style top. It's a fair size and weighs a ton. The alloy use is an offshoot of a CNC self-build that went from horizontal to vertical, hence I had a left-over (and very expensive) base that was crying out for use.

The alloy has multiple channels which perfectly fit the Festool clamps so generally I have used this method to clamp wood to the side of the bench however this has not been the best approach most of the time and I really need a proper vice. Anyhow I've always liked the Moxon style vices but wanted to add my own touch and whilst I believe they are probably worth the money I couldn't justify that cost for something I can make myself, especially not when I wanted three vice's around the bench.

So I bought some Record 53 clones from Rutlands over the weekend with one of their 10% offers. These are effectively Record 53 derivative clones and copied by various suppliers from Axi to Eclipse, etc. They are not as tall (or heavy) as some of the usual suspects but given they will have wood backers this is kind of irrelevant to me. Also at £36 (with offer) a vice this is an absolute no-brainer for me and they are not too bad in quality.

I then removed the screw;

Set in the lathe and turned the end down to 22mm to this;

I then bought some 8" alloy cast hand wheels which were drilled out to 22mm;

Refitted to the vice with a tapped M5 grub screw;

And here is the finished vice;

Will post pics when fitted to the actual bench. The aim is to have two on one side and one on the end.

Anyone needing a vice or a replacement, although I haven't used them in anger yet I can't see how they can be churned out for >£40.

Any comments / advice appreciated.